Intelligent screening empowers printers

The phenomenal power of computers and the algorithms which run on them is visible for all of us in our daily lives – adverts are digitally ‘served’ to us based on our browsing preferences, age, location, searches, etc. Today’s AI (Artificial Intelligence) enables Amazon to inform us about products which we might like based on our previous purchases.

Information technology and innovation have changed the world we live in, and the same is true for print.

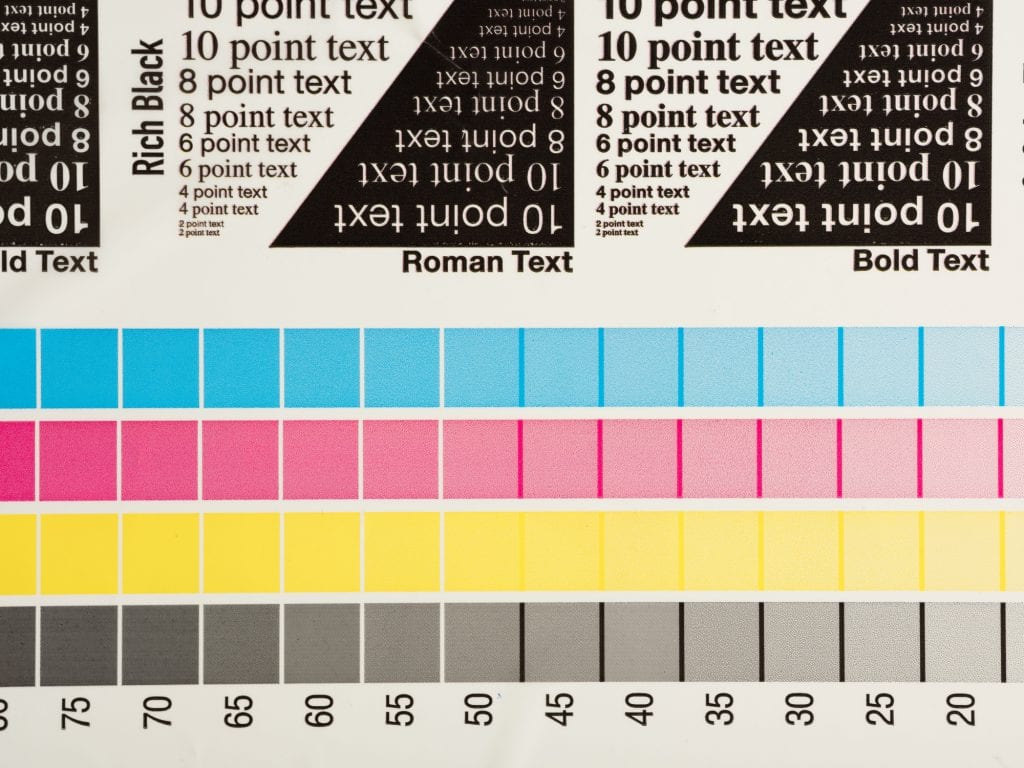

The invention of halftone screening came about over one hundred years ago. In the interim, printing and screening technologies have advanced and evolved but, perhaps surprisingly, we find that the original AM halftone screen is still the most commonly used – this is because, despite having access to many different and newer halftone screens, these alternatives do not address all the key problem areas and are not as compelling as AM.

Introducing the ‘intelligent algorithm for print’: Digitally Modulated Screening (DMS).

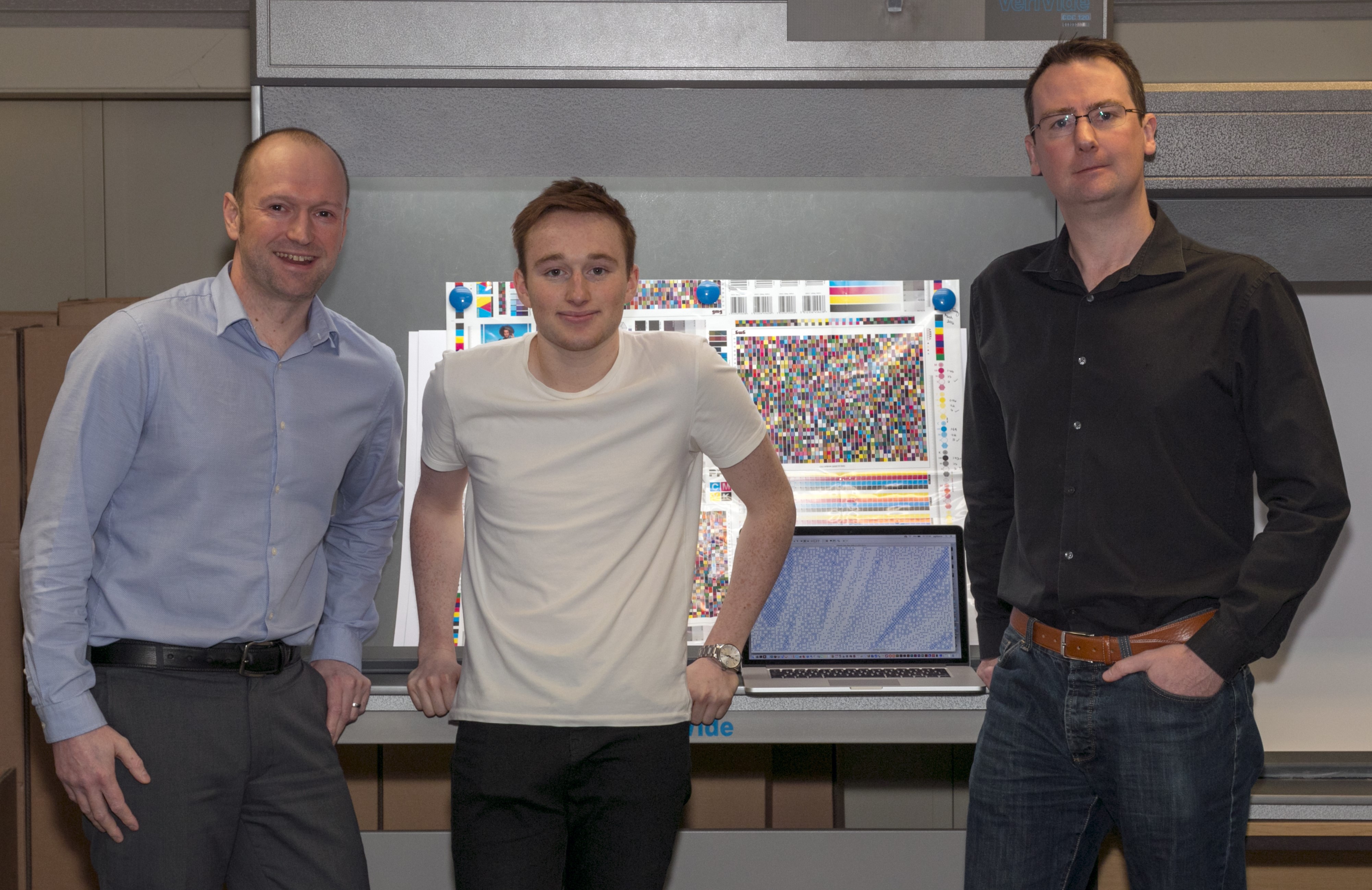

Hamillroad Software’s patented Digitally Modulated Screening (DMS) harnesses the phenomenal processing power of modern computers to overcome the issues with existing screens. This new invention has been developed into a product over the past ten years and is designed to overcome the inherent problems with traditional halftone dots – whether AM. XM or FM

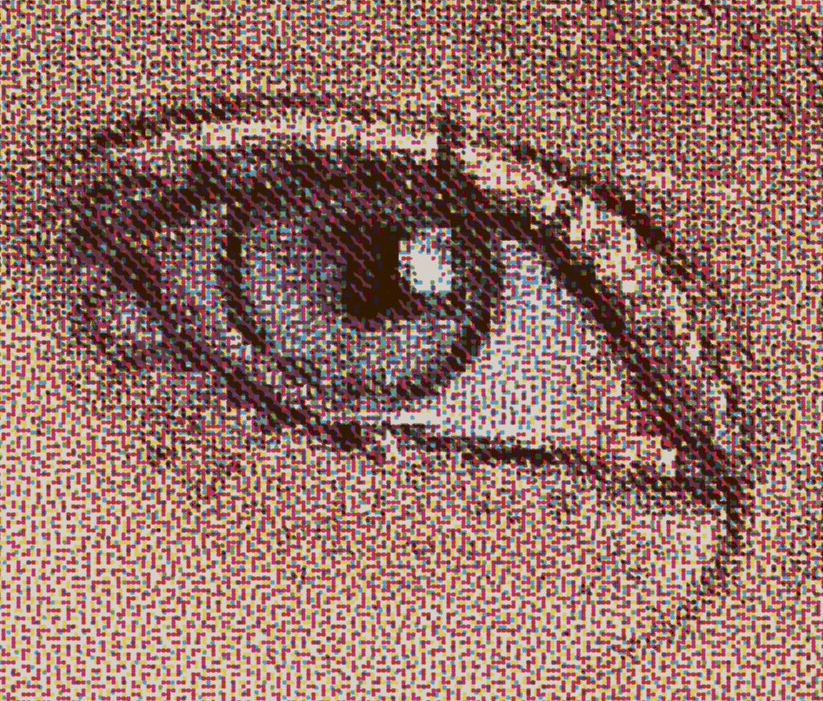

Halftone dots are a necessary evil in printing; however, print customers don’t want to see them and their potential artifacts in their print. Instead, they want to see their images reproduced as originally intended: moiré free and rich in detail.

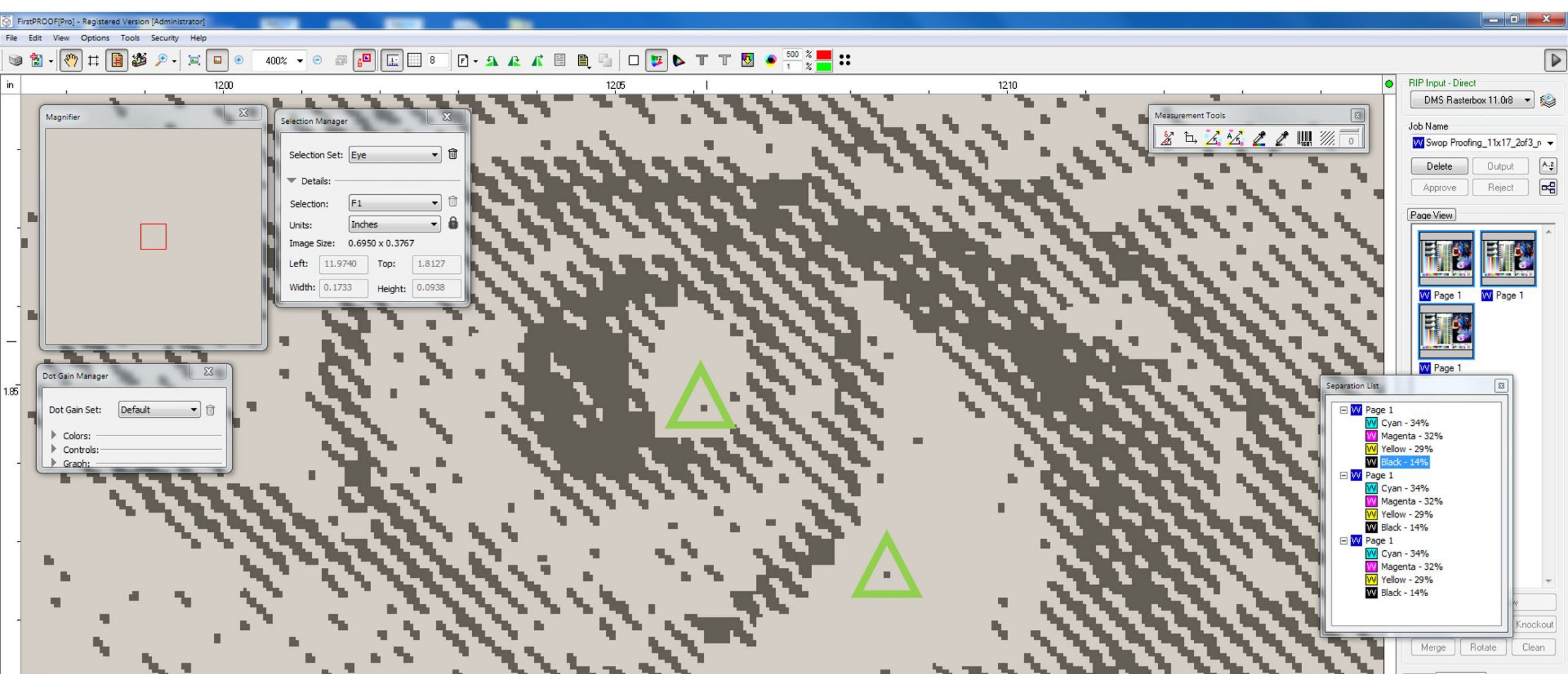

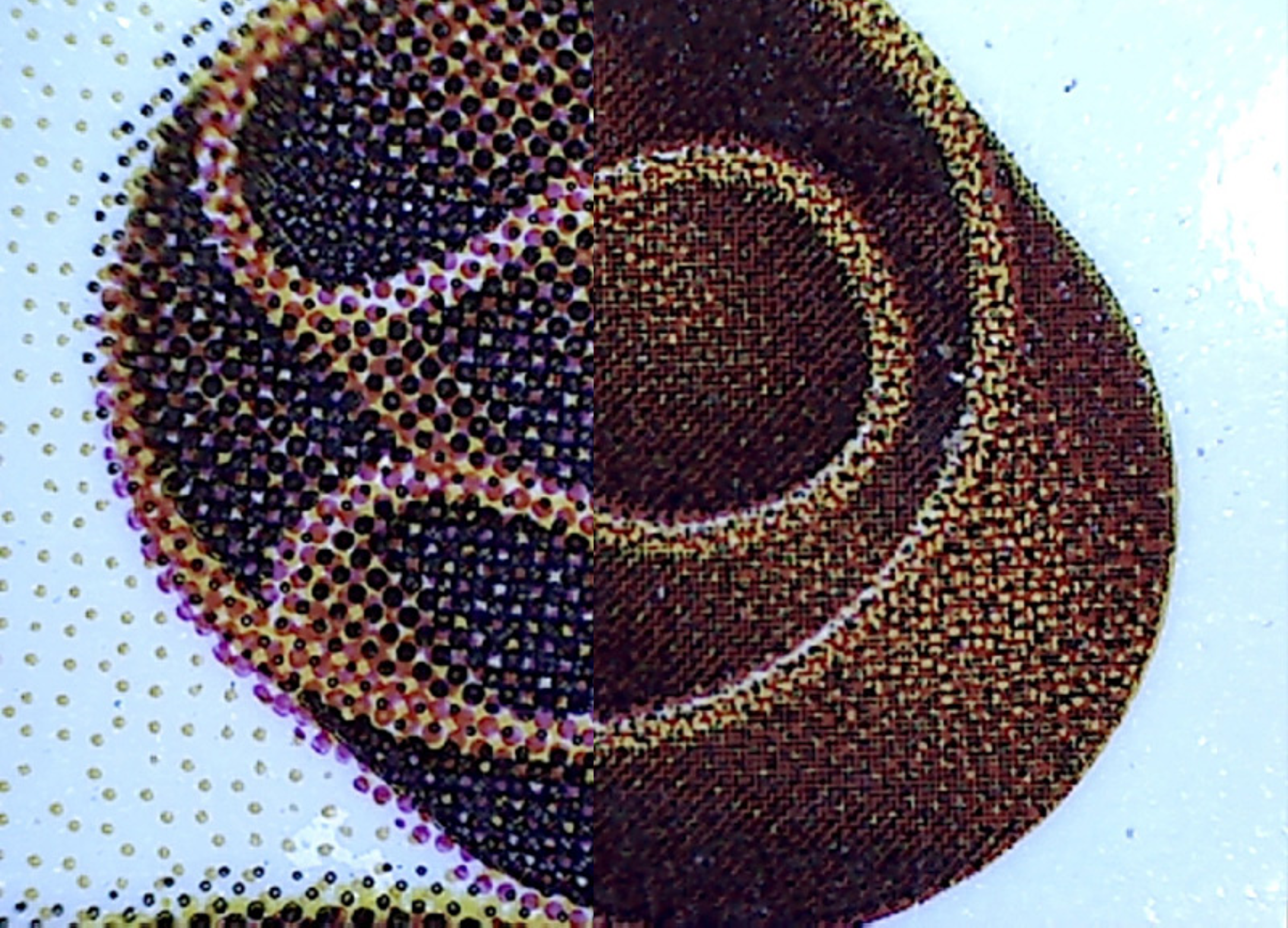

DMS can be summarised as ‘intelligent screening on steroids.’ DMS is unique in that it digitally decodes an image during the rasterizing process and intelligently analyzes the image to determine exactly where on the plate the dots need to go together with their correct sizes and shapes. The DMS halftone dots exhibit two extremely important characteristics: rendering images with dots which are small enough to produce near-photographic fidelity in print while also being robust enough to be stable in a real-world production environment. DMS results are more reliable and consistent and produce less waste than conventional AM dots.

In the dog eat dog world of print, printers are pushed and squeezed from all angles to deliver the highest quality product at the lowest possible cost while still meeting the exacting standards and demands of the print buyers.

The goal of magazine publishers is to sell magazines, but they care even more about selling advertising space to the brands which keep them in business. If advertisers do not feel that the fidelity of their print advertising does their products justice, they may pay less or, worse, take their business elsewhere.

Auraia DMS was developed specifically to address the issues of delivering the highest quality presswork at the lowest possible manufacturing cost.

Auraia is Hamillroad’s implementation of DMS technology for offset / litho and it is compatible with web heat-set, cold-set, and sheet-fed offset presses.

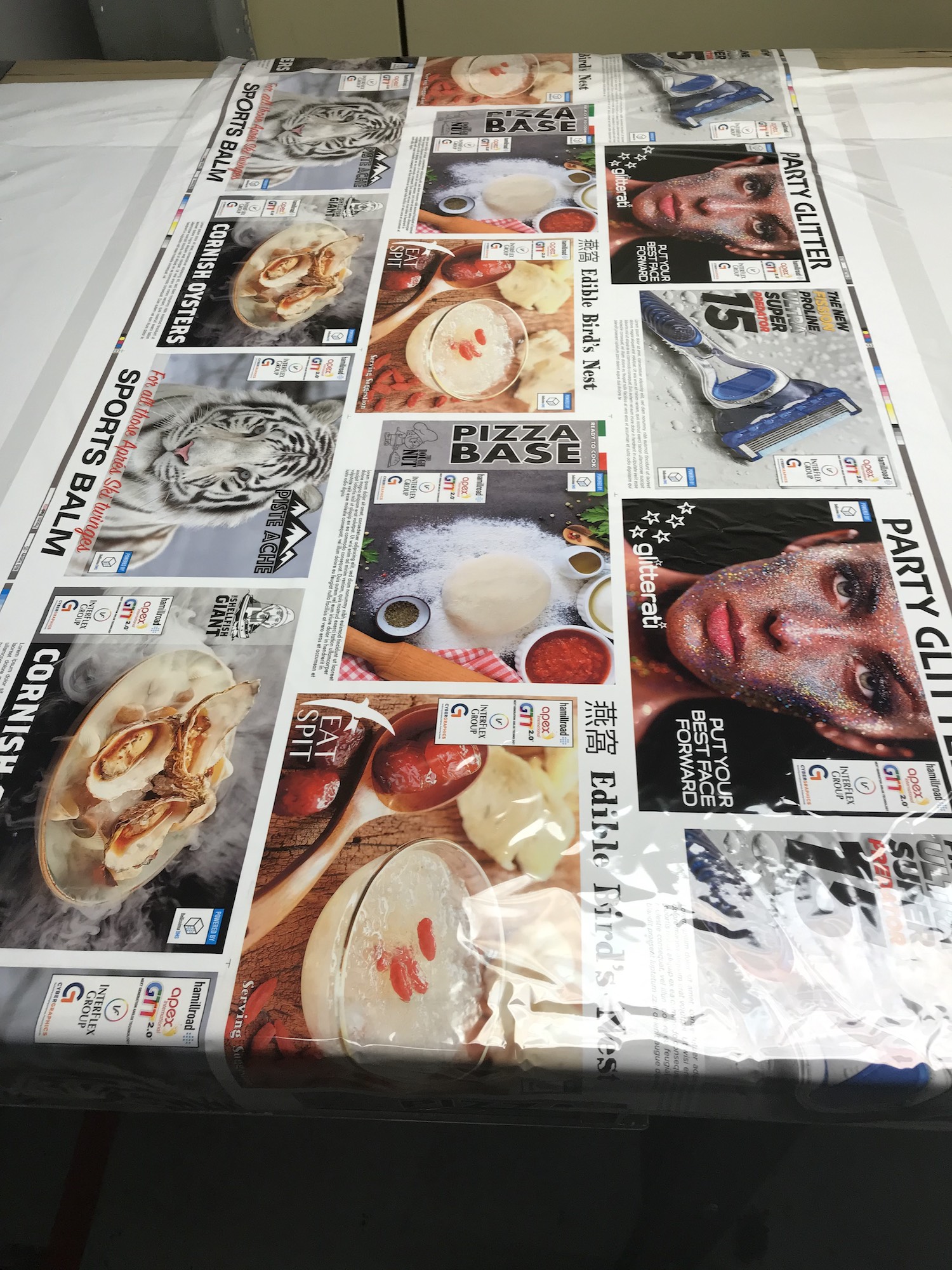

Auraia DMS enables customers to easily print at a higher effective lpi than their competitors (200-250 lpi for newspapers and 400-500 lpi for commercial printers) delivering photo-real image quality to clients. And, in addition to the benefits of enhanced quality, printers also benefit from the inherent ink savings in the range of 12 – 18% (delivered over and above GCR savings), reduced waste, and lower energy bills. Auraia DMS customers usually show a very attractive ROI within the first 12 months. Millions of magazines, catalogues, advertising brochures, books, and other printed materials are printed using Auraia every day.

Our biggest clients prohibit us from naming them, as they do not want their competitors to find out the name of their ‘secret sauce’.

And now intelligence comes to Flexo screening.

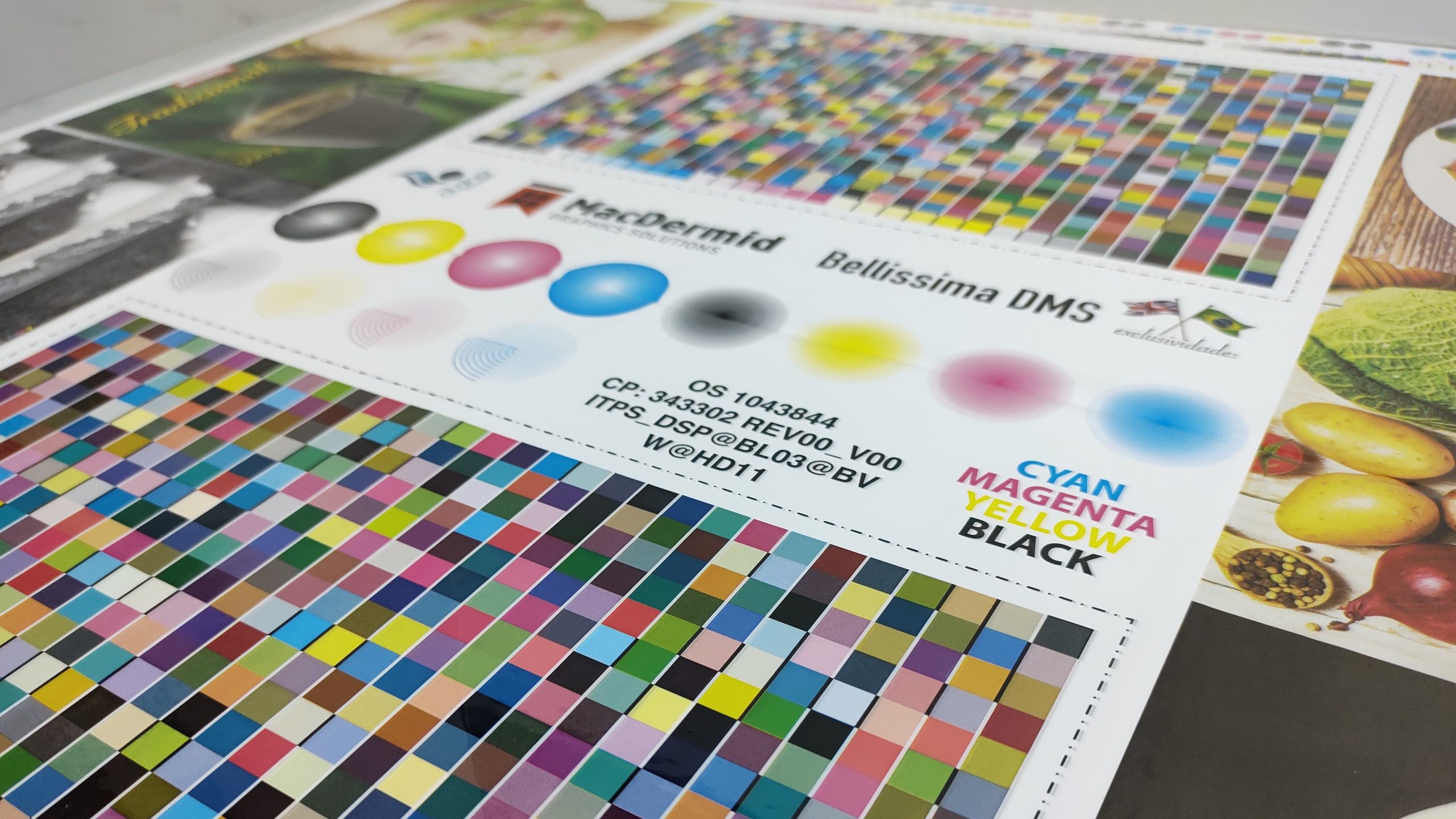

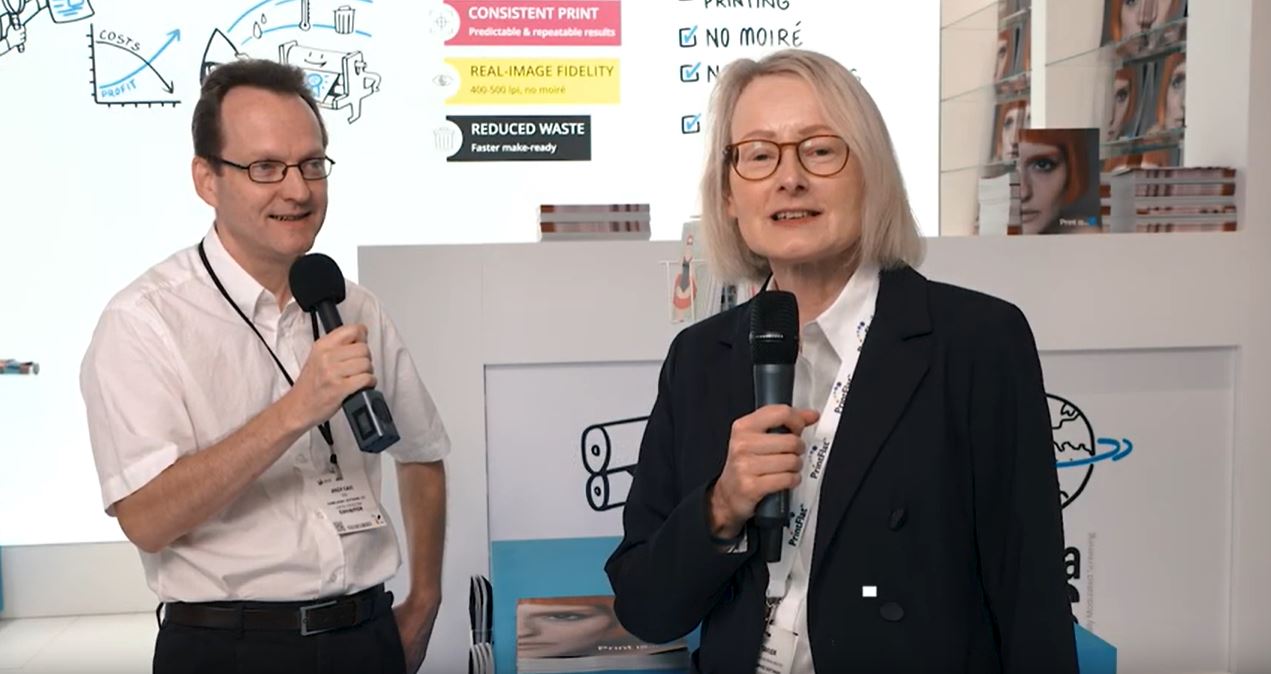

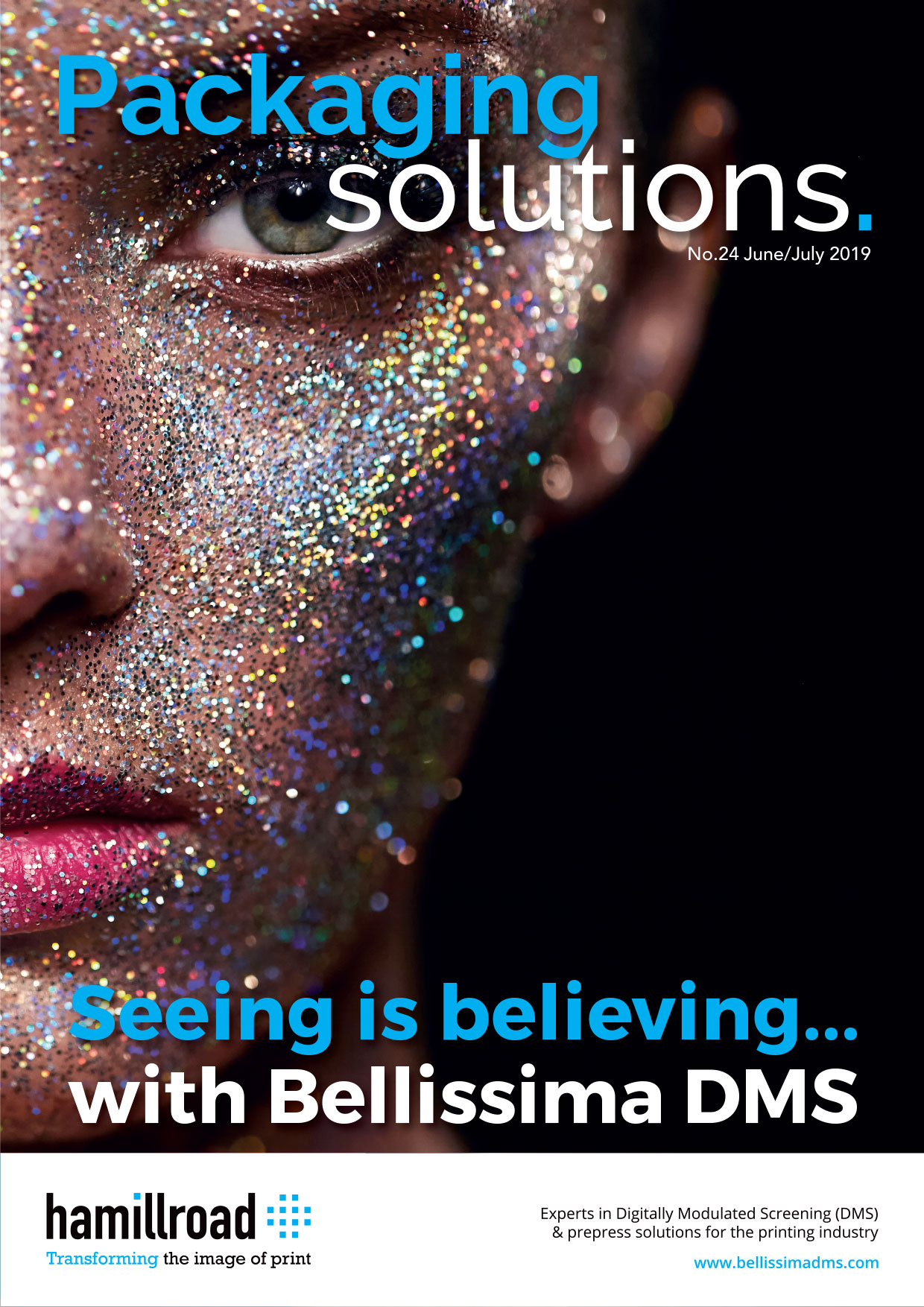

Launched at LabelExpo in September 2017, Bellissima DMS has scooped multiple innovation awards since its release.

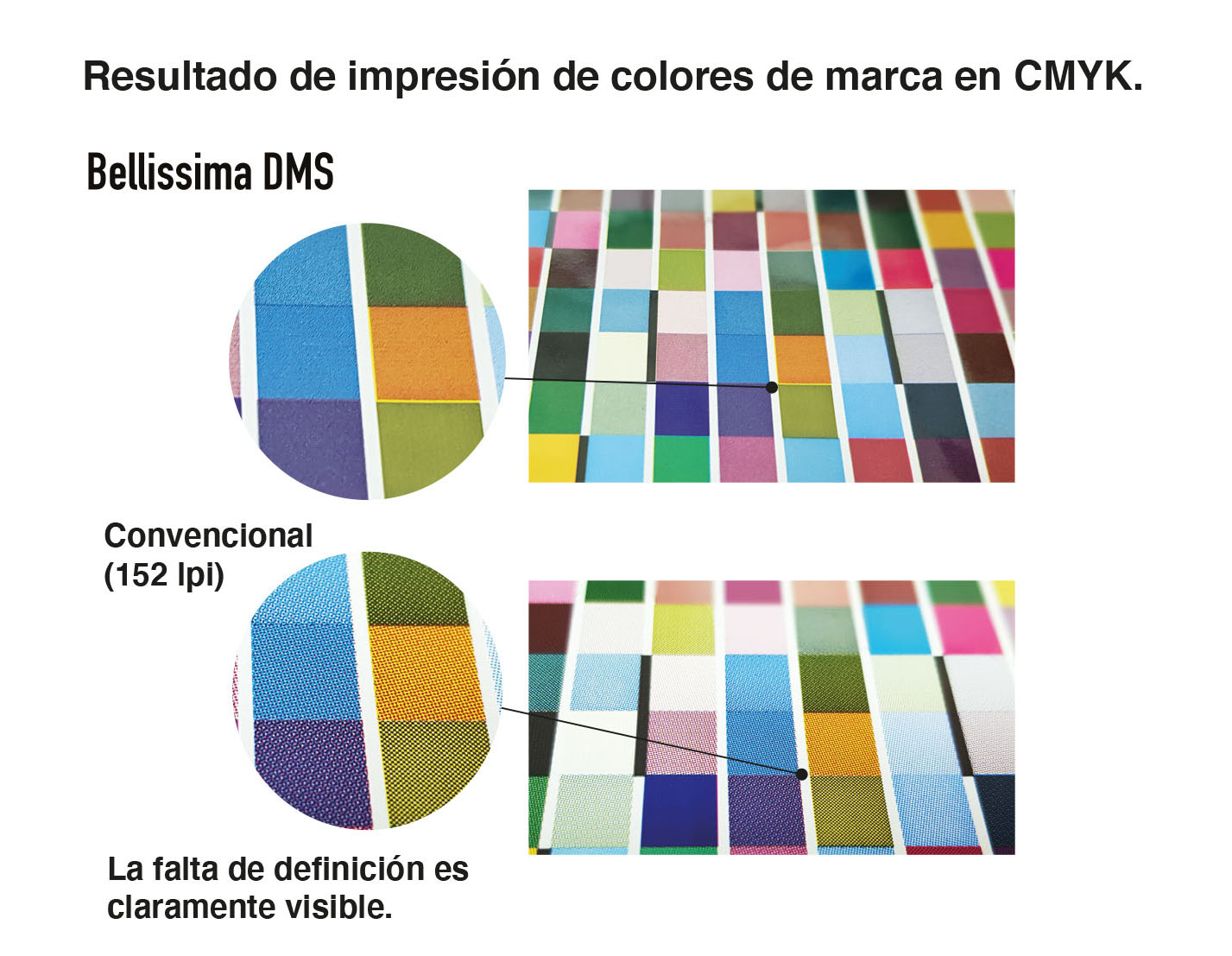

Bellissima DMS does what Auraia does, but it does it for the unique, specific, aspects of flexo printing. Bellissima DMS rasterizes the input and, intelligently, determines the correct shape and size of dots to use, as well as determining exactly where the dots need to go on the plate according to the image being printed. The halftone dots are small enough to be invisible to the naked eye, but they are large enough to withstand the rigors of the printing process. The dots are positioned to support each other on the plate, and this provides them with strength and stability to withstand even the most aggressive of bounces on the press all while delivering near-photographic fine detail and delicate vignettes.

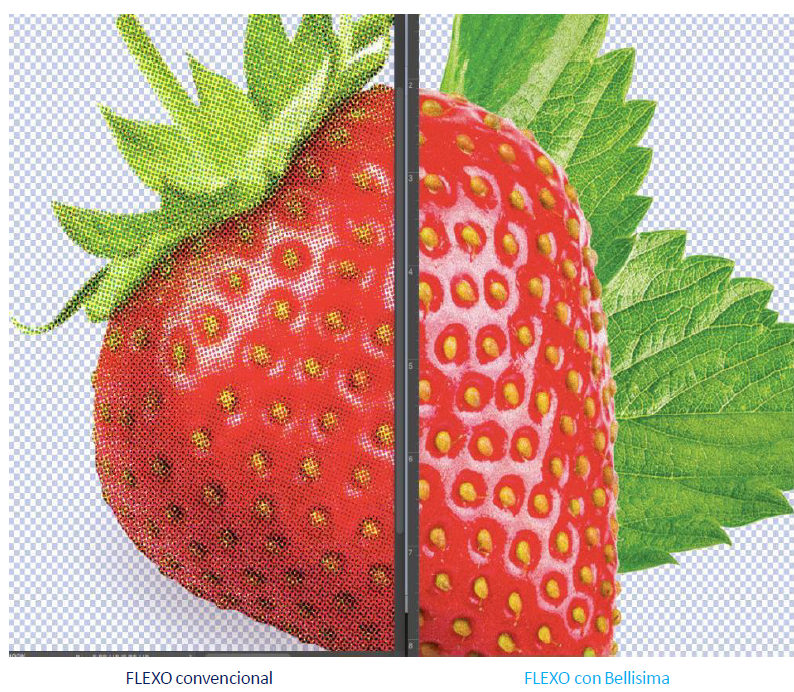

Historically, flexo was regarded as the poor cousin of offset. However, Bellissima’s arrival has shattered long-held beliefs about the limitations of flexo print quality and is forcing brand owners and printers to take a serious look at flexo’s new potential. In fact, in side by side comparisons of Bellissima vs. offset, the flexo printing often wins hands down on the image fidelity scores. Some have even said that it rivals gravure.

That’s what technology should do; it should disrupt, cause a stir, and provide tangible, outstanding, value to its users. DMS does so in a way which gives flexo more than a fighting chance of surviving in a world where print needs to achieve more with less. By enabling older technology to compete with the new digital kids on the block and allowing it to do so at a fraction of the cost of the capital expenditure typically required for new technological investments.

With DMS screening, the future of flexo now looks brighter than ever.