Auraia DMS (Digitally Modulated Screening) is a patented intelligent screening technology designed for the lithographic offset printing environment, that uses a unique and smart algorithm to lay down carefully controlled and robust dots on plate. The result is faster make-ready, and a more reliable production experience, so that you can print more chargeable jobs!

In addition, Auraia DMS is proven to reduce costs compared to conventional screening technologies, delivering real-world ink savings, as well as a reduction in waste, water, and energy. Crucially, there is no compromise on quality – Auraia DMS is held in high regard for its ability to produce photo-real image fidelity in stunning magazines, catalogs and books.

Quad has been using Auraia DMS for more than six years across its global heat-set printing operations including the United States, Peru, Colombia and Mexico, as well as at its European operations in Poland, and today Auraia DMS is its screening technology of choice.

How can Auraia DMS help reduce costs,optimise your heat-set print production and win new business?

Commercial benefits

- Proven ink savings

- Reduce blanket washes

- Less water and fountain solution

- Save energy – quicker drying

- Make ready waste reduction

Real world ink savings

" The printing result is convincing with very high detail and a fantastic brilliance. Images get an almost photo-realistic representation and colored surfaces appear printed as a spot color. In addition, we save about 20 percent of ink. "WALTER KNOPP, OWNER, OFFSETDRUCK KNOPP, GERMANY

Maximize your heat-set profitability

- Attract new clients and compete on price without compromising on quality

- Print more and invoice for more jobs in the same time period

- Win new business & retain customers with consistent 'photo-real' image fidelity

- Add value and help customers meet their sustainability goals

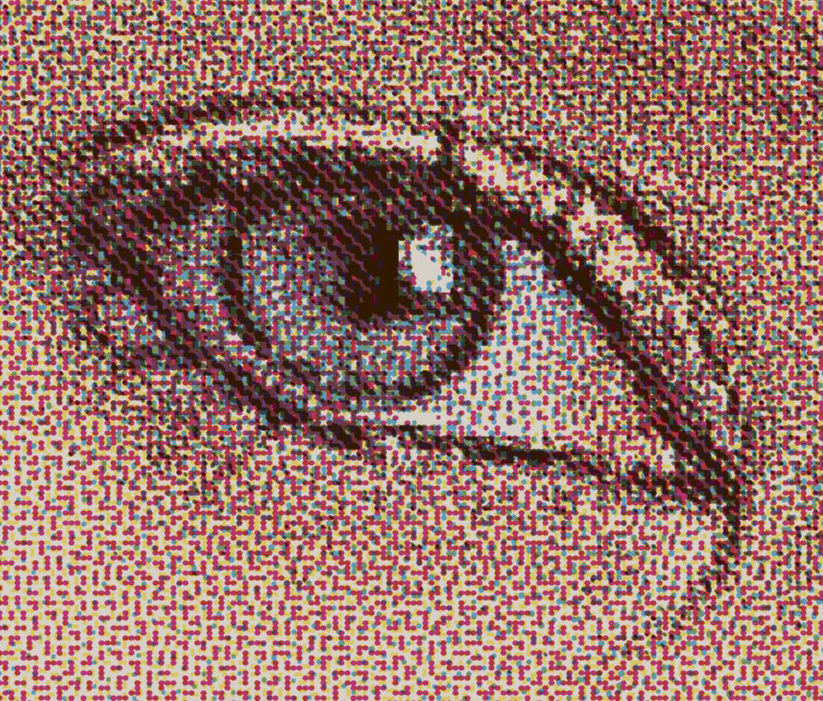

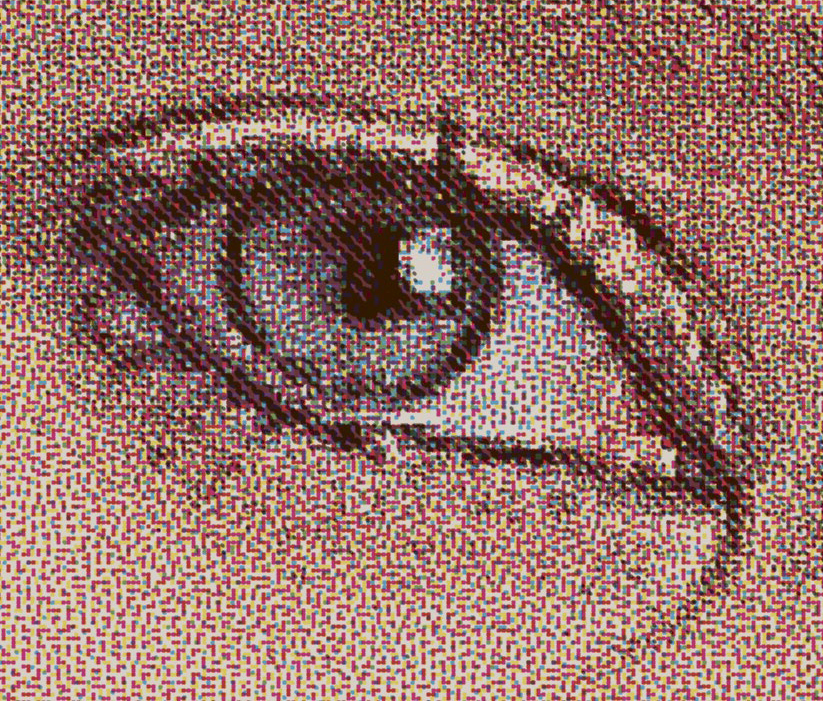

Auraia’s intelligent dots....

Auraia’s clever algorithm ensures that no dot is too small to plate or print yet still not large enough to be visible. The result is visually stunning ultra high-definition printed magazines and catalogues, not possible to achieve with conventional screening methods. No longer are printers restricted by problems with moiré, misregistration, rosette drift, color shifts, banding, dot gain variation, dot or shadow loss and so on, but are free to do what they do best – meet their customer expectations with ‘beautiful’ presswork.

Auraia DMS is the smart choice for publication printers and is proven to reduce costs, delivering real-world ink savings as well as a reduction in waste, water, and energy.