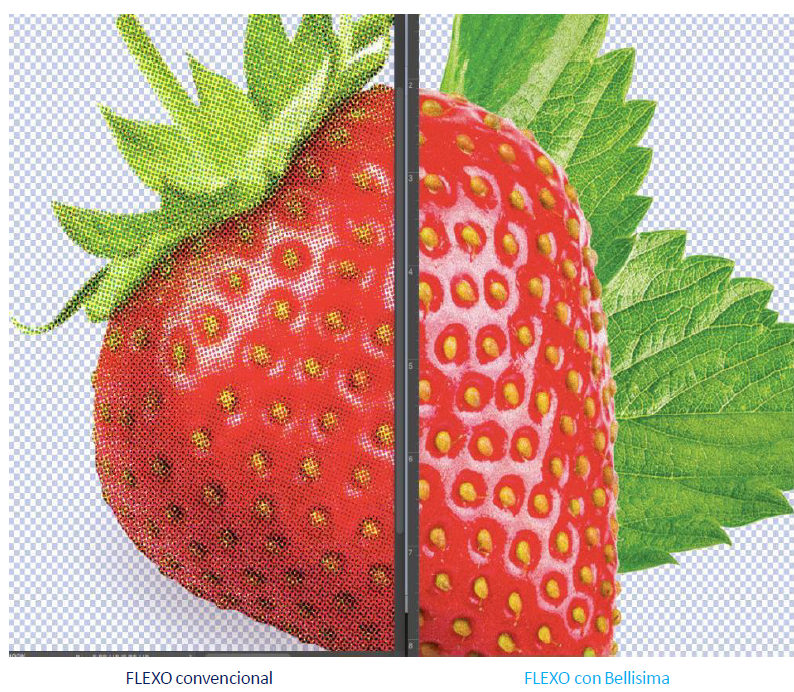

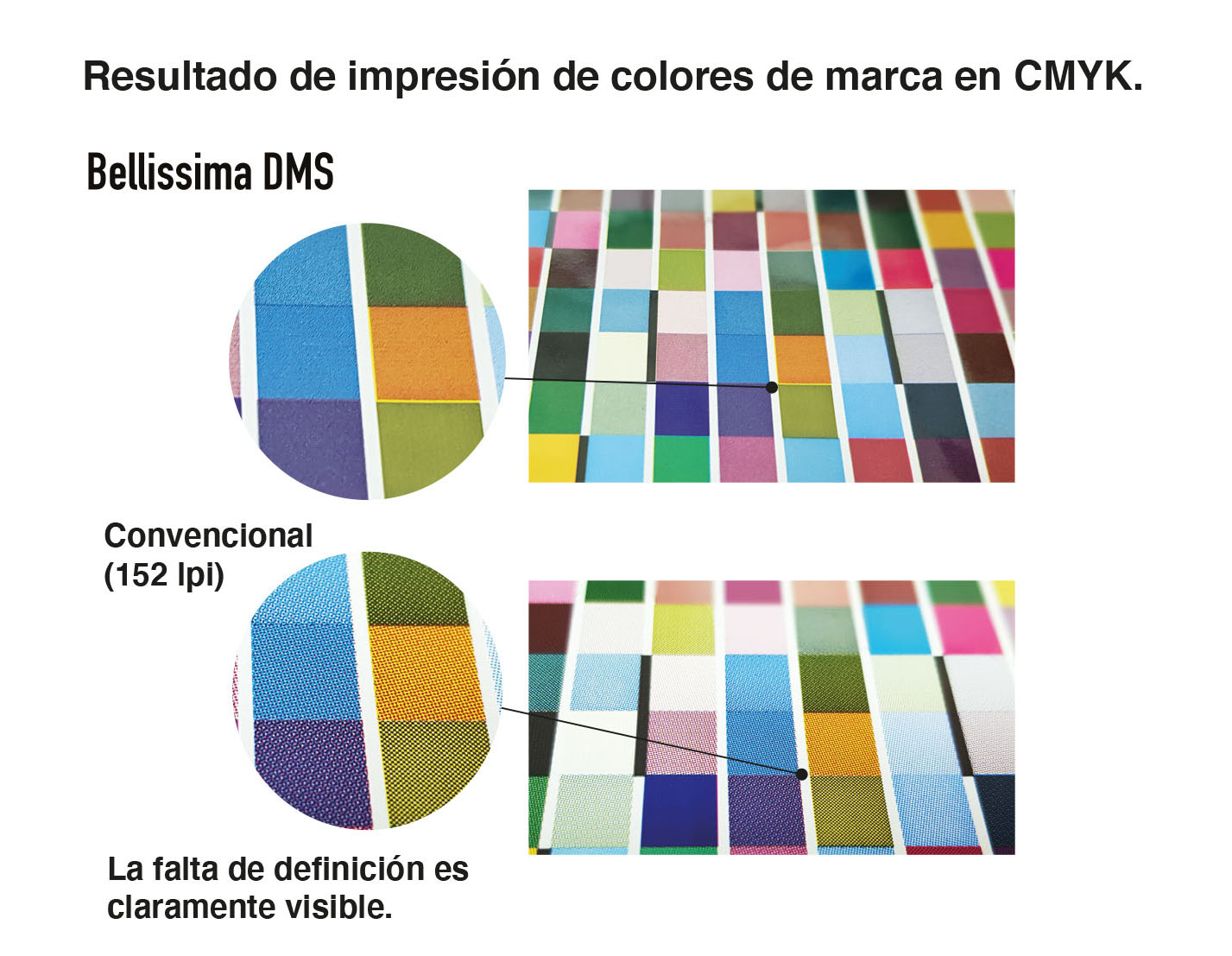

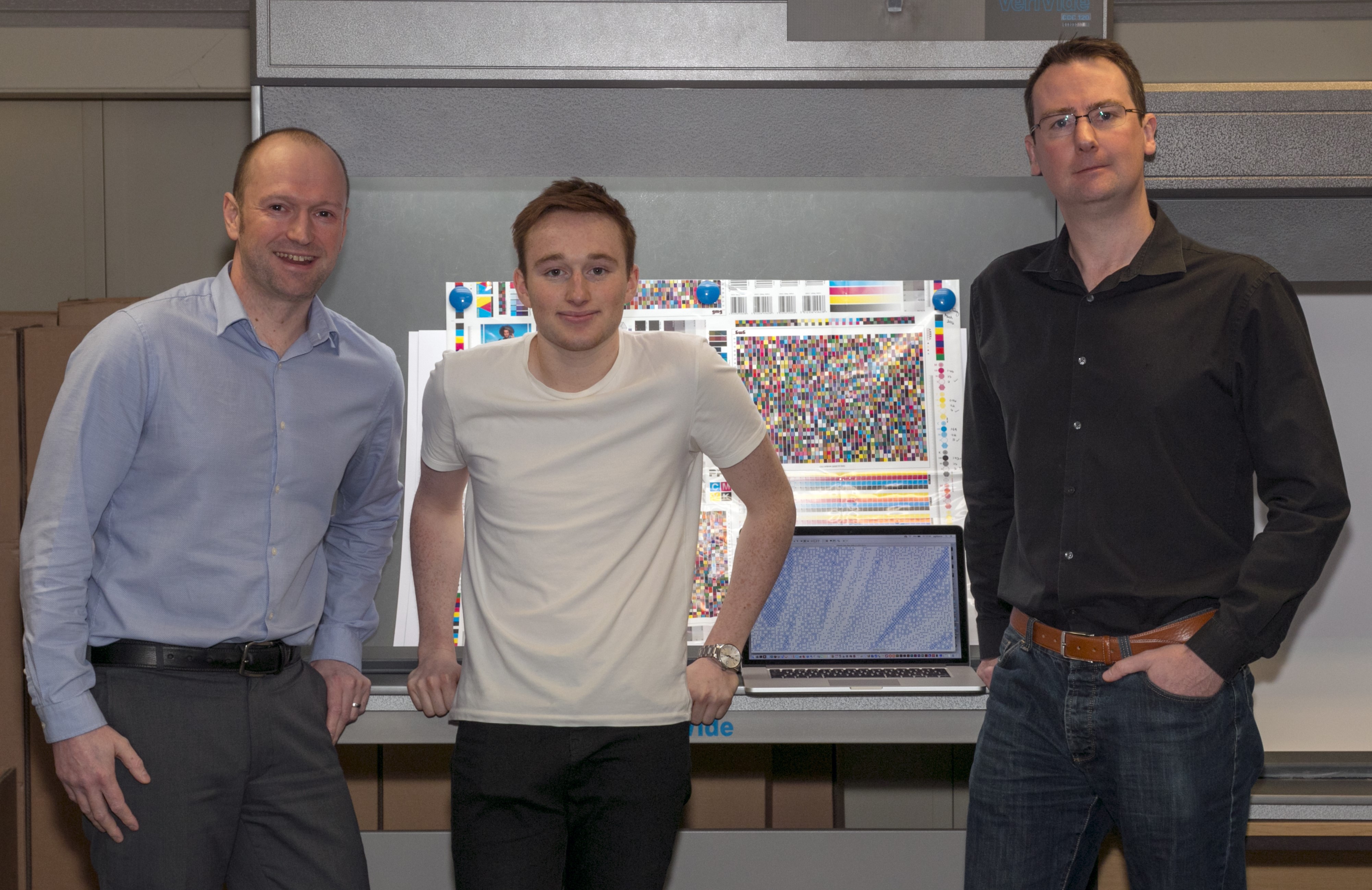

Emsur shows a resolution never seen in Flexography

Bellíssima, the new technology adopted by the Valencia plant, is positioned for its image quality as the future of flexible packaging and labels.

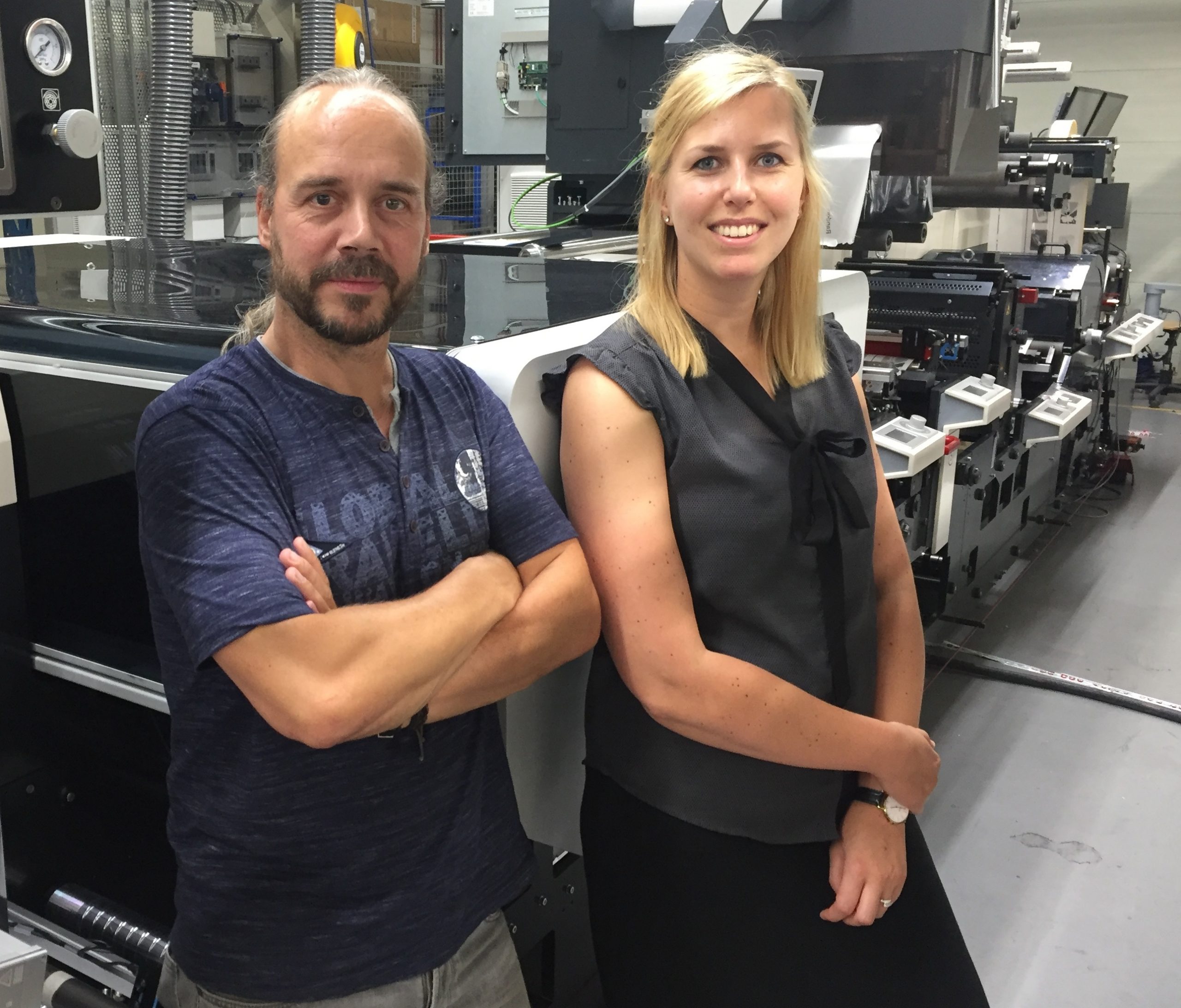

Madrid, 28th May 2020. – EMSUR Valencia Saymopack is to be congratulated. The Spanish flexography plant of the Emsur group, specialized in the market of snacks and pastries, coffee, fresh products and personal and household care, has opted to incorporate into its offer the new technology developed by Hamillroad, a new concept of screening without considering the plot angle. It is called Bellissima, an innovative technology merging the best frame features like AM, FM, XM, GS and CS.

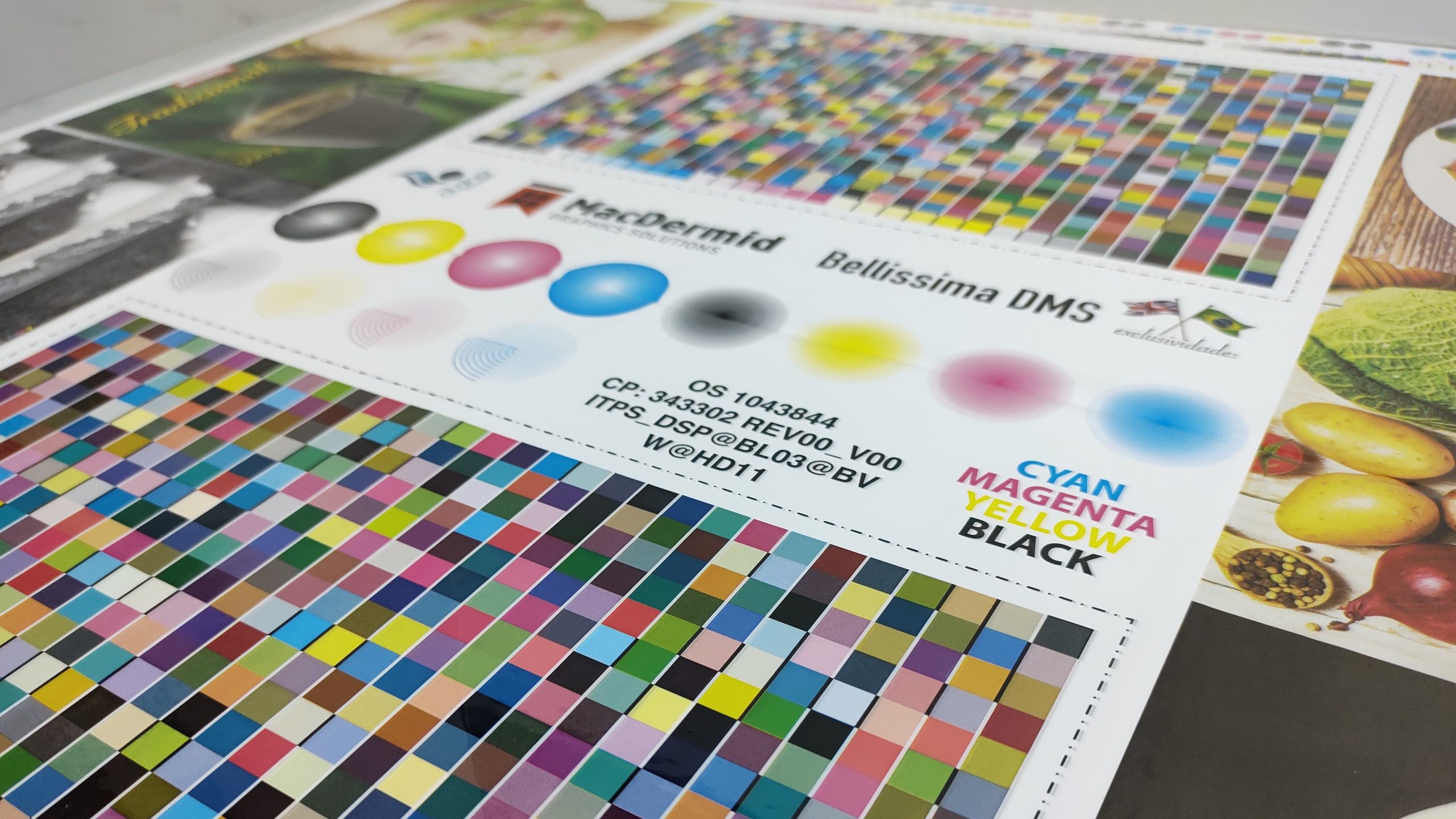

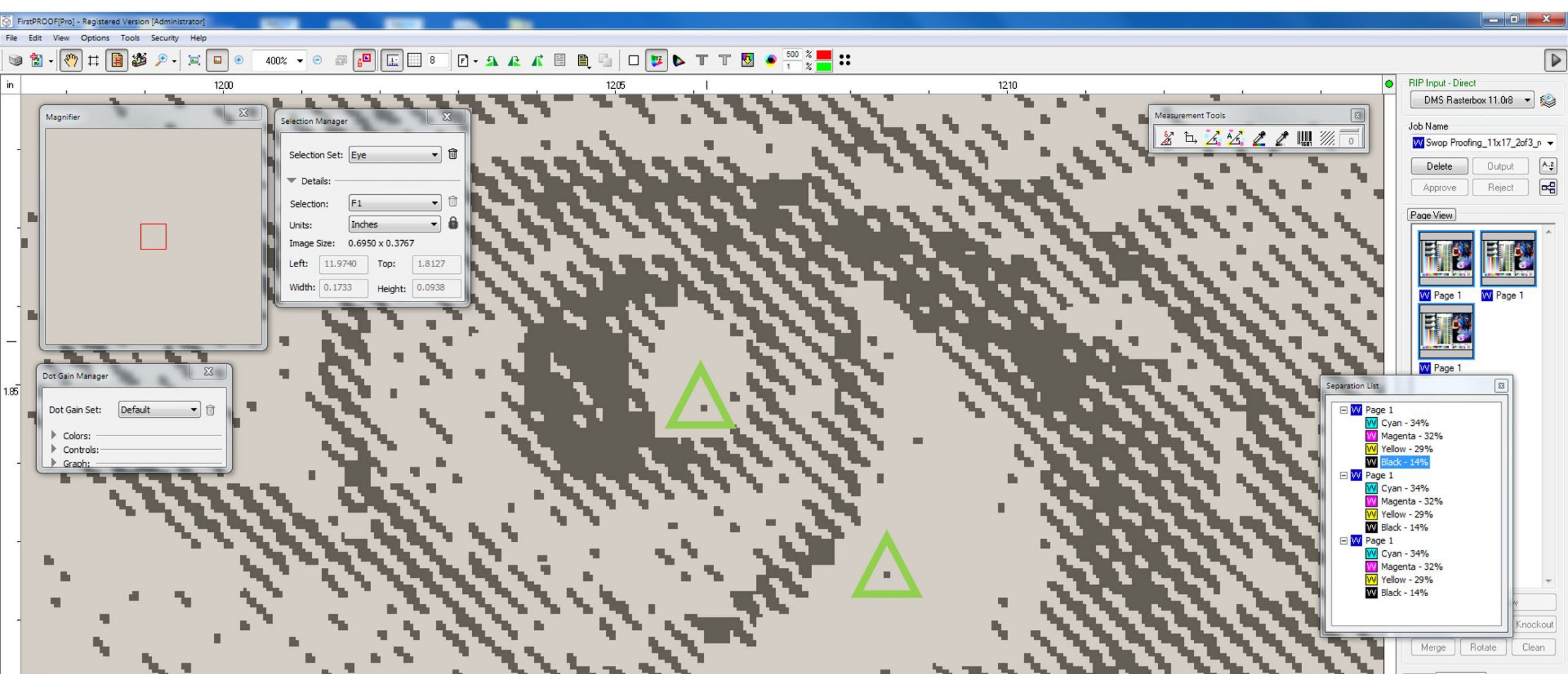

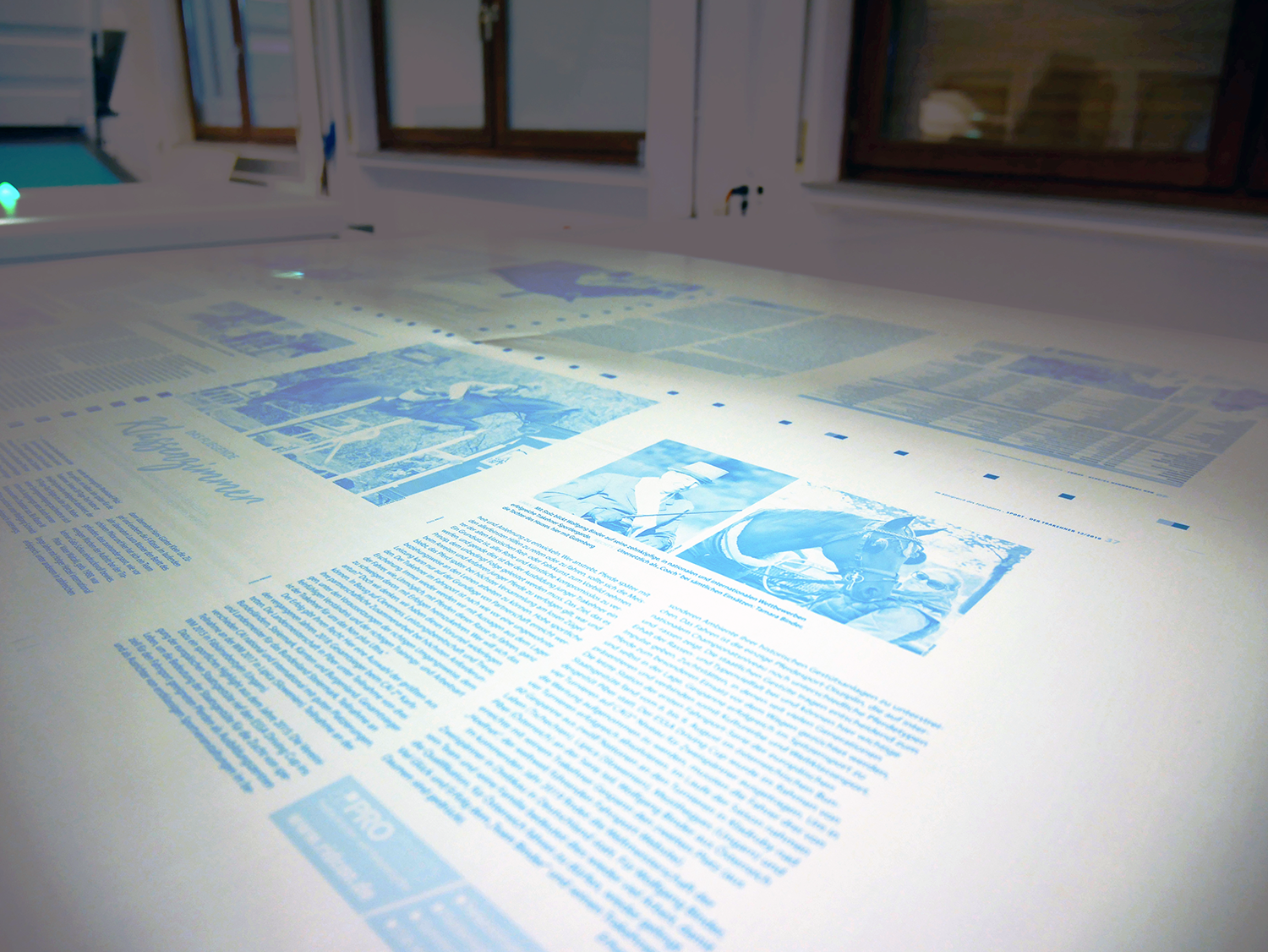

Bellissima, distributed in Spain by Flexographic Solutions, uses Macdermid (IT60) flat point plates for its printing, reducing the point size to 19 pixels and eliminating the vision of the tracing point. By not using in-line highlighting, raster angles per color, or anilox trim, you need Apex Open Cell Anilox (GTT) technology.

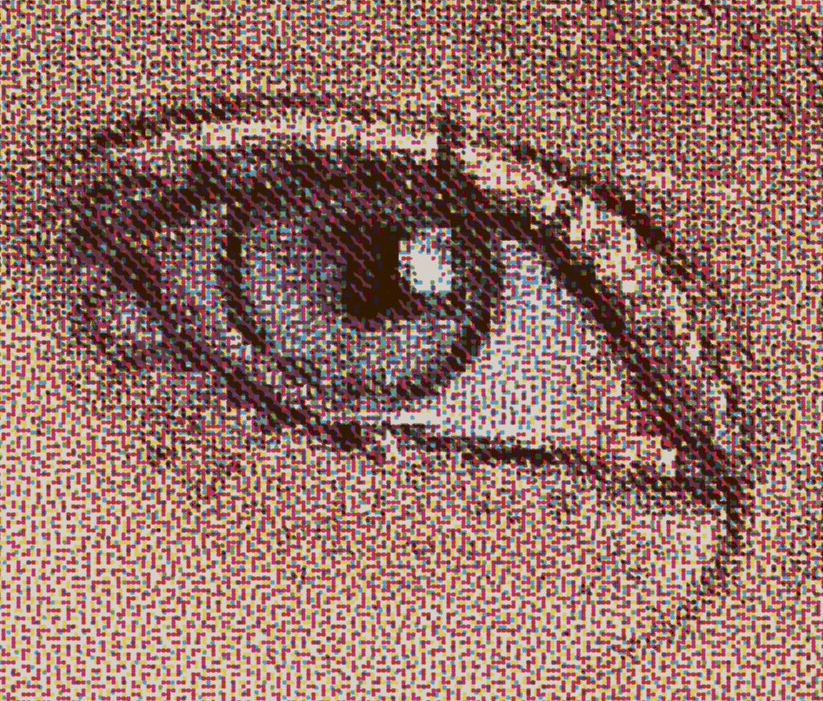

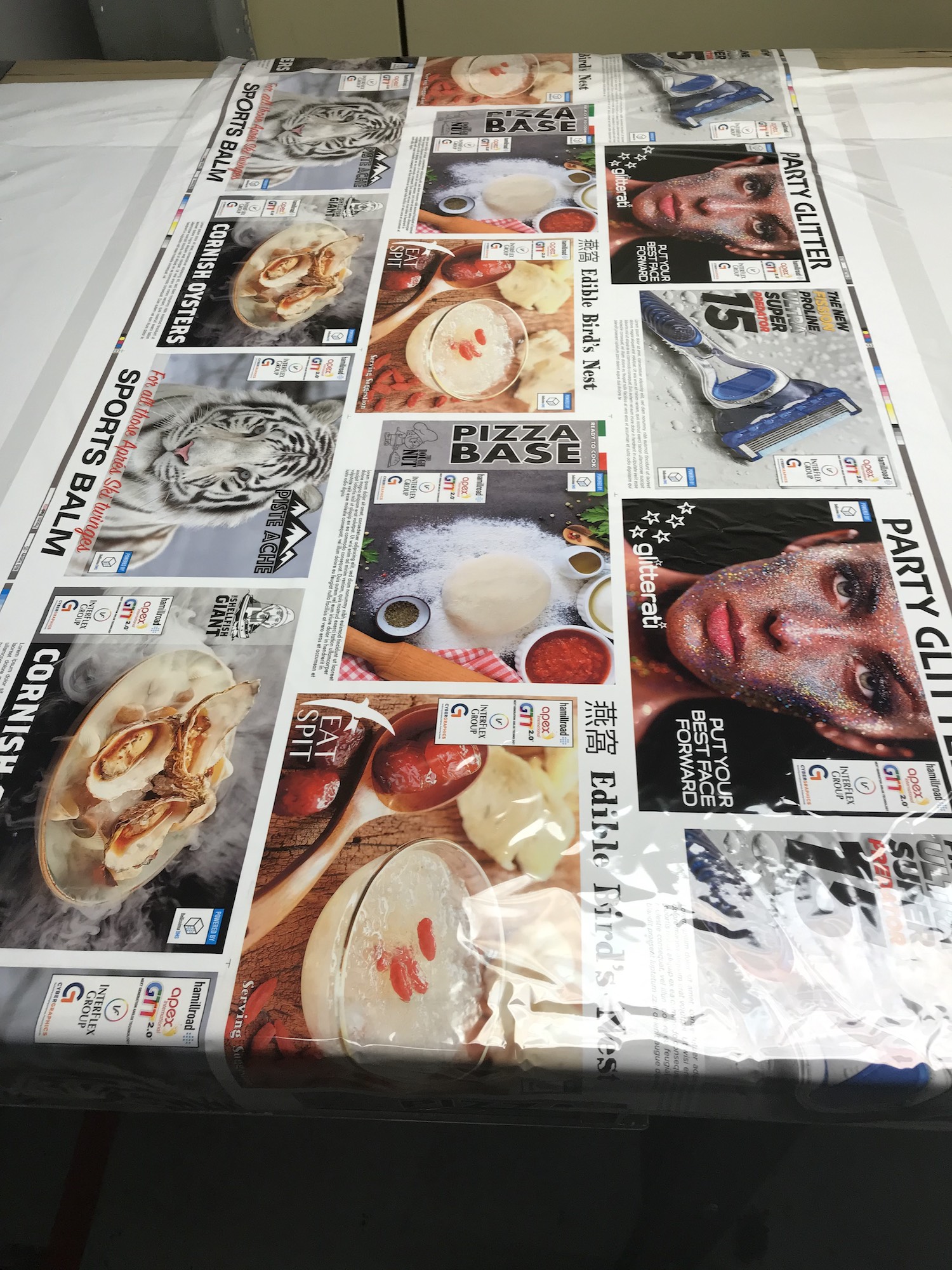

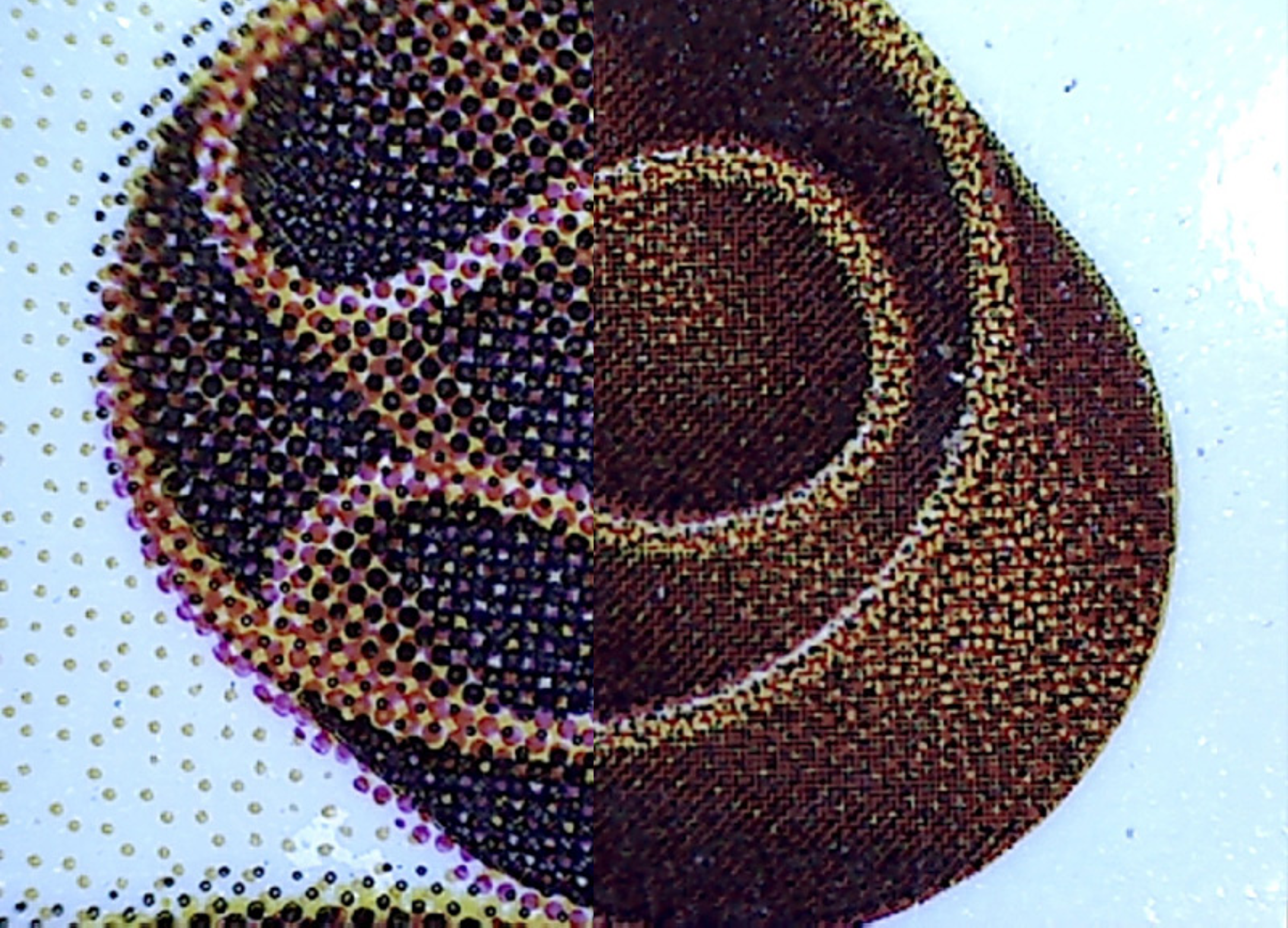

By overriding the moiré and improving registration problems, you get high-quality prints that EMSUR Valencia Saymopack can currently develop for your flexible packaging solutions.

In addition, Bellissima optimizes the amount of ink on the substrate and minimizes the amount of ink on ink, expanding the range of available colors, while eliminating color changes due to incorrect registration. Outcome? print quality never seen on the market, particularly on flexible substrates.

Some of the most exclusive Bellíssima benefits:

- High quality prints (450lpi). Increased contrast

- Moiré free

- Gradients to “0”. No color shifts

- Not visible dots

- Smooth flat tints

- Improved text quality, better patterns cut, better definition

- Improved image registration

- High solid ink densities

- Bounce reduction and bending. Calculated in the Bellissima algorithm development system

- Optimizes the amount of ink used

Read online at Emsur: https://www.emsur.com/emsur-flexography-bellissima/