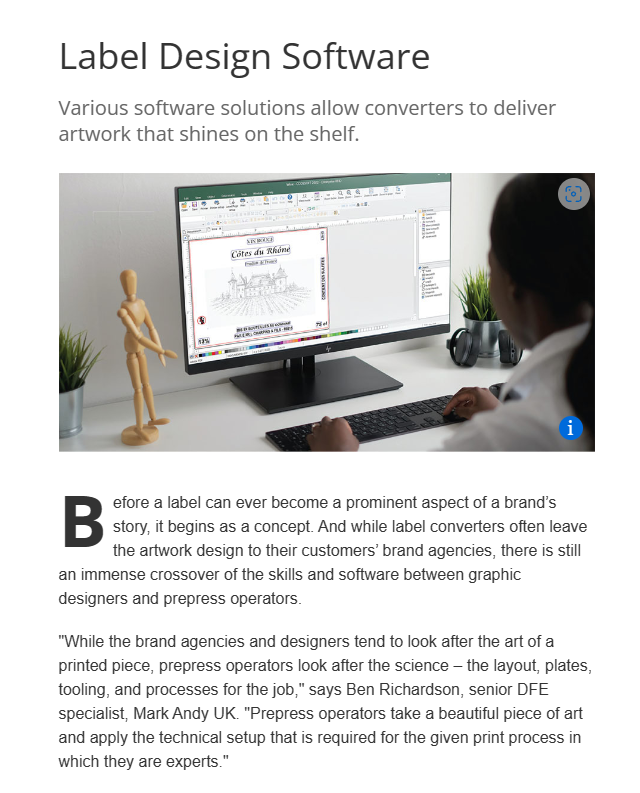

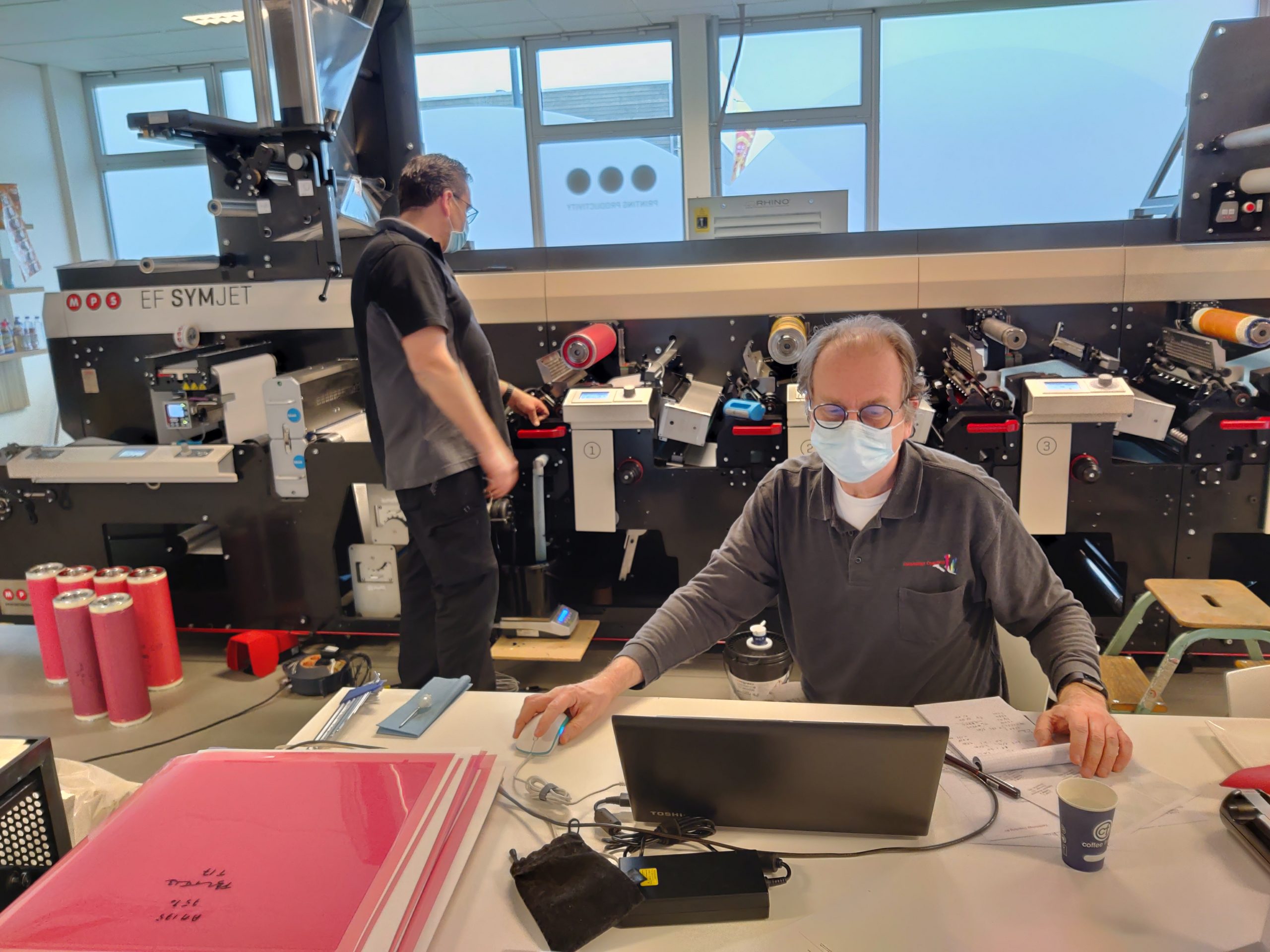

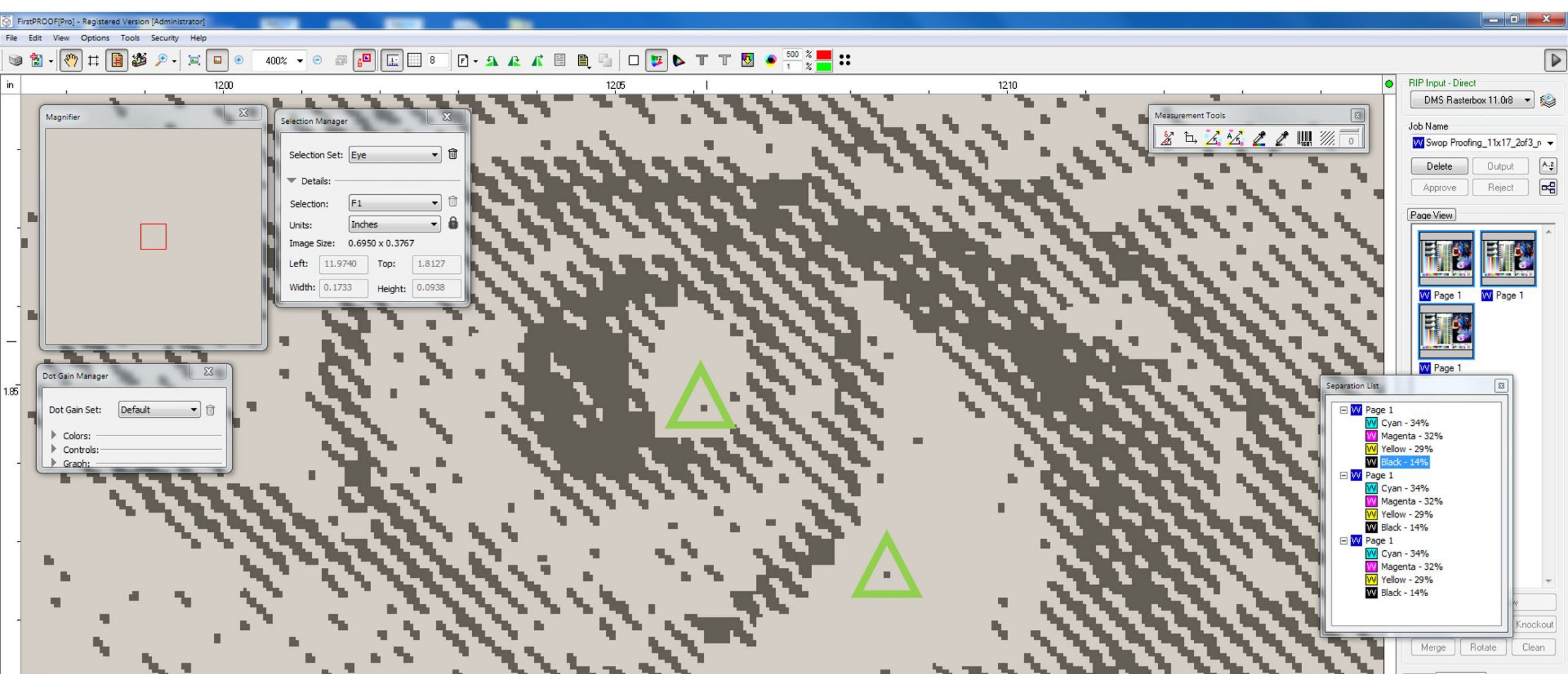

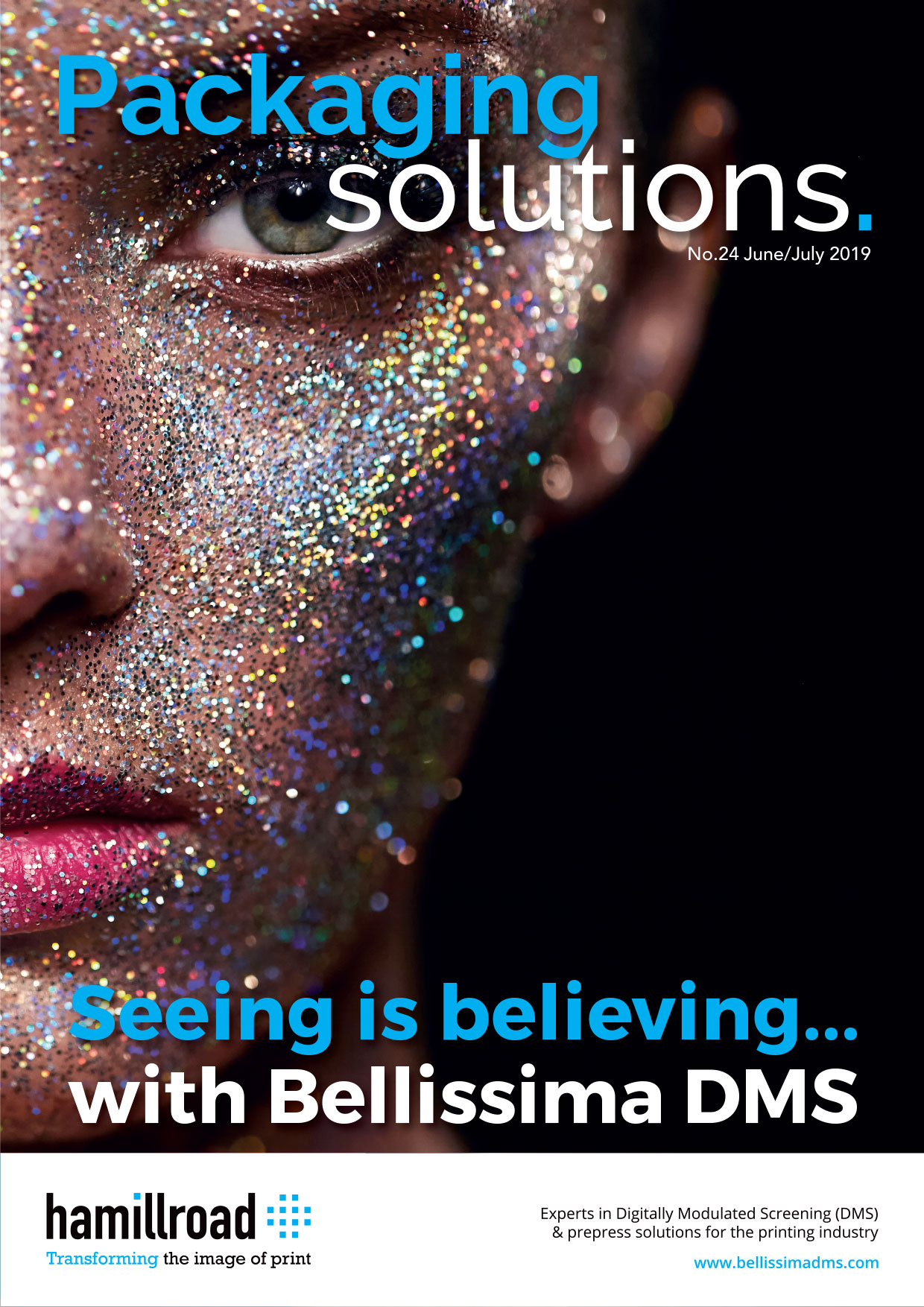

Joe Settanni of Apex International explains the benefits of using Bellissima DMS screening technology.

APR Technical Summit tackles screening

Greg Hrinya, Associate Editor 21 August 2019

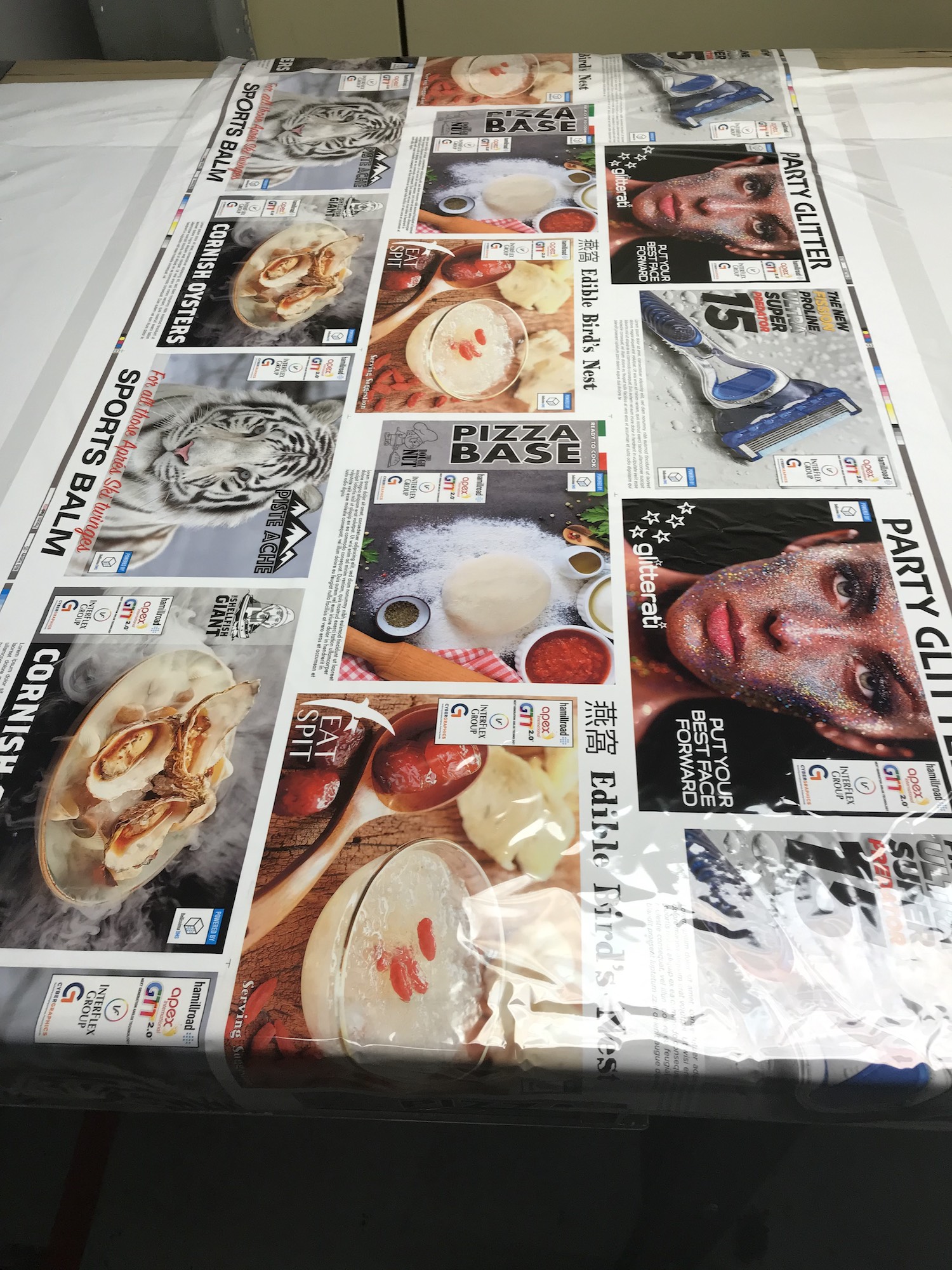

During a two-day event, All Printing Resources (APR) welcomed attendees to its facility in Glendale Heights, IL, USA, where the latest advancements in flexography were on display. APR invited a host of players from the labels and package printing industry to explain how flexo is being positioned for the future.

APR partners, including Apex International, Esko, Harper, MacDermid Graphics Solutions, and Siegwerk, delivered presentations on the state of flexo–and specifically how their technologies tie into the screening process. APR’s Catherine Haynes moderated the first day of the Technical Summit, themed “Advancements in Screening.”

The second day of the event, with a “Lunch & Learn” theme, featured advancements in the flexo pressroom, including cushion mounting products, flexo safety auxiliary products, Lean productivity protocols, new color matching metrics, and new training processes.

“In the last five years, screening has really been what’s taken the flexo industry to new levels,” said Haynes. “I love the concept of being able to automate this process.”

Perhaps not the sexiest industry products, the technology on display at the APR Technical Summit is every bit as responsible for producing an image that pops off the shelf–from the anilox roll to the ink.

“There are all these fascinating technologies that are developed, but if you don’t do the rudimentary processes you’re going to struggle with your print,” said Harper’s Sean Teufler. “Ultimately, there are a lot of factors that could affect your print.”

As printers look to enhance image quality, screening has emerged as a key driver. Larry Moore, VP Channel Partners, North America, for Esko, and Joe Settanni, business development director – North America for Apex, explained how XPS Crystal and Hamillroad Software’s Bellissima DMS, respectively, are helping converters achieve better printing results.

According to Moore, Esko’s Print Control Wizard takes the guesswork out of platemaking. “There’s a lot of art that still goes into the flexo process that, to be as efficient as possible, we need to get to a manufacturing process,” he stated. “We want to minimize our roles as much as possible and maximize the manufacturing process as much as possible. That’s the whole goal behind a product like Print Control Wizard.”

Crystal’s screening technology comes in various versions, which can be tailored to each printer’s application, press configuration and platemaking environment. Since producing custom screens and curves has traditionally been a manual and time-consuming process, Print Control Wizard has been developed to simplify this step for labels and flexible packaging.

“Print Control Wizard allows you to set standards based on your print process,” noted Moore. “That can coincide with whatever color standards you’re using today. It will walk you through everything you need to do in the process.”

The product quickly formulates data sets for screens and curves, creates print targets (mid-tone targets and highlight targets), maintains a Dot Gain Chart, and allows for the entry of various parameters like what plates are being used, thickness, ink set, anilox properties, and so on.

Moore added that by saving just five minutes of make-ready per job, printers could see annual savings of roughly $43,000.

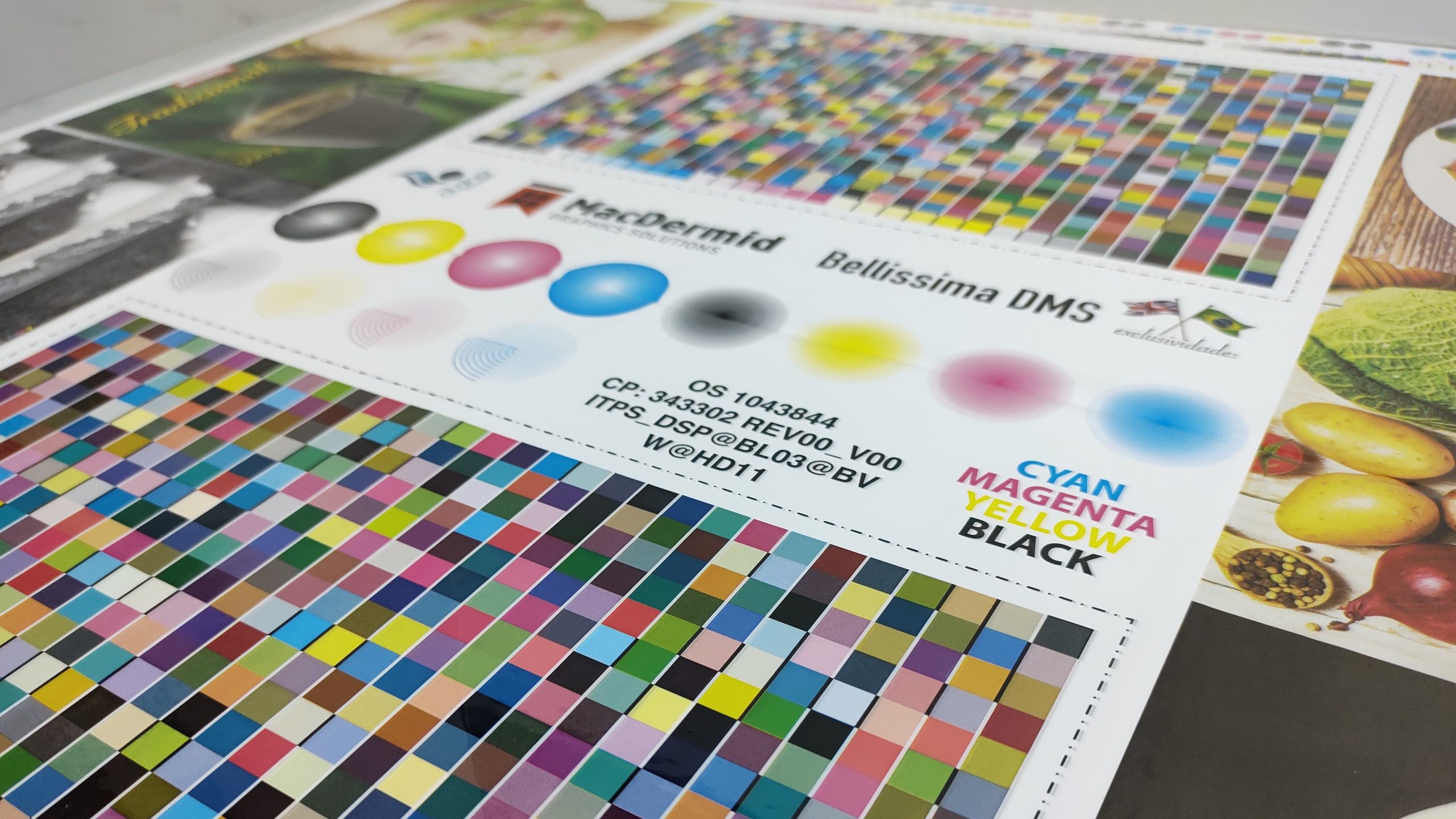

Apex’s Settanni, meanwhile, cited his company’s success as the distributor of Hamillroad’s Bellissima DMS. This technology has been optimized for use with Apex GTT anilox technology and with plate partners such as MacDermid.

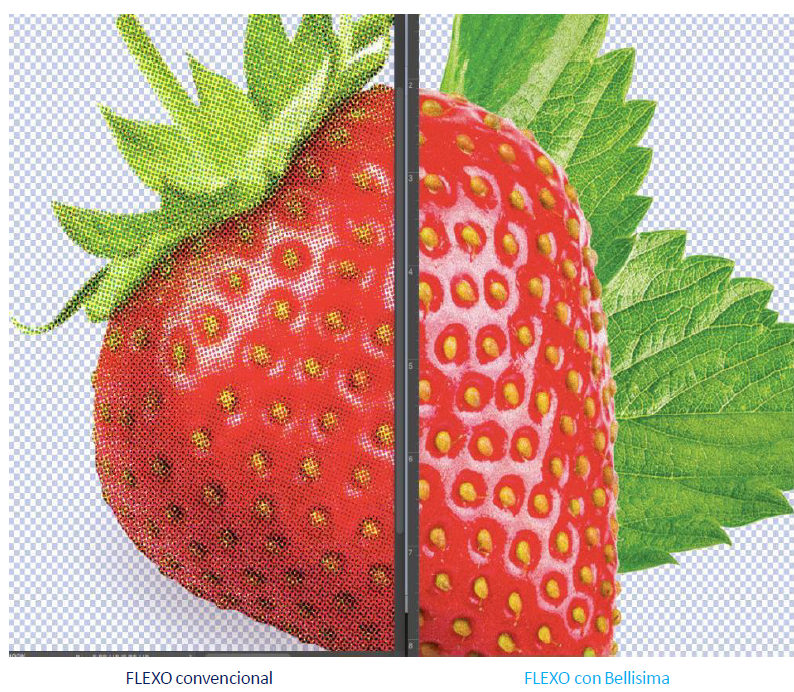

“I’m not here to say digital is going away,” said Settanni. “It’s not a fad; it’s here to stay. But I think there has been a segment of flexo that has been pushed to digital because of quality, and we think we have the technology to bring that business back to flexo.”

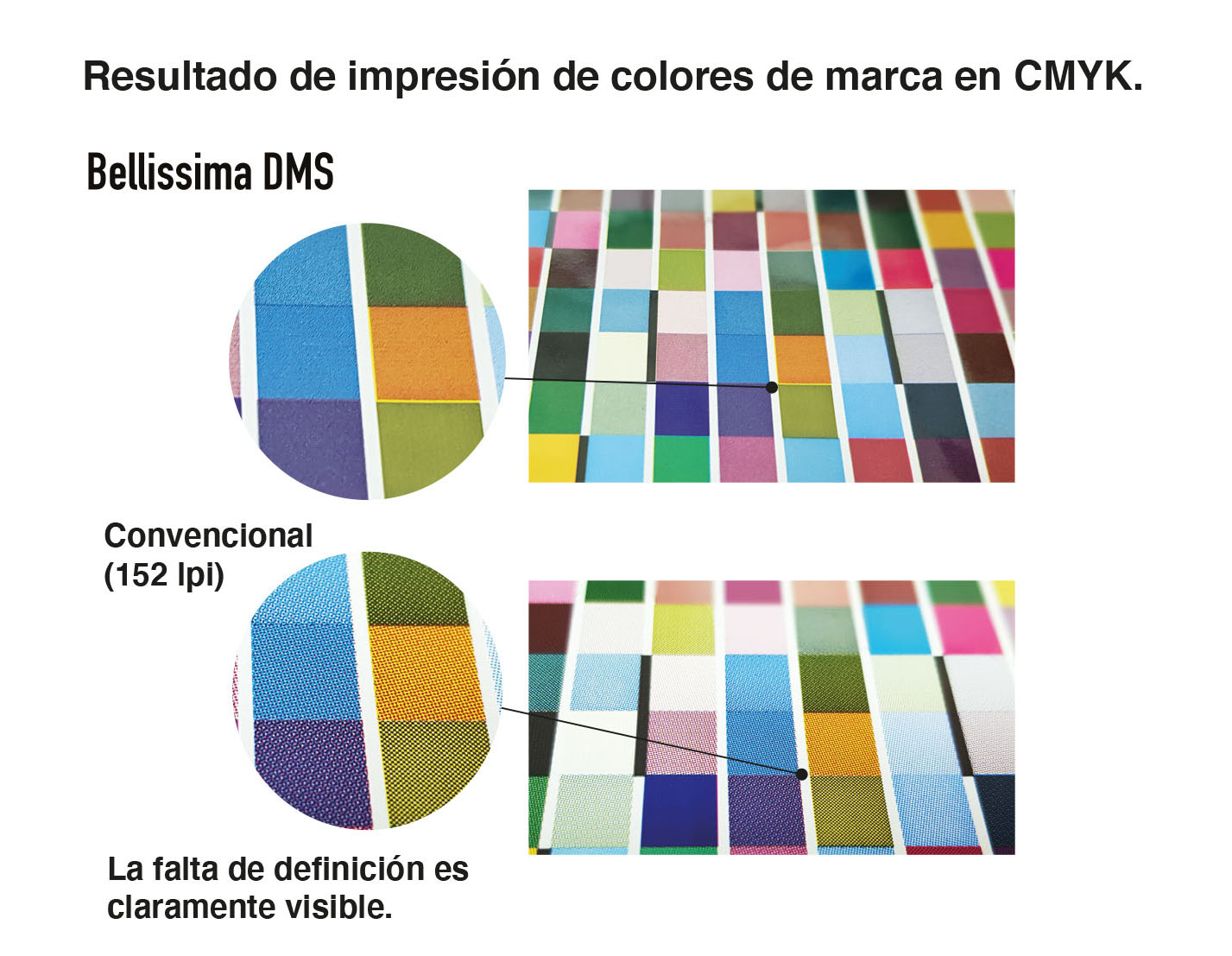

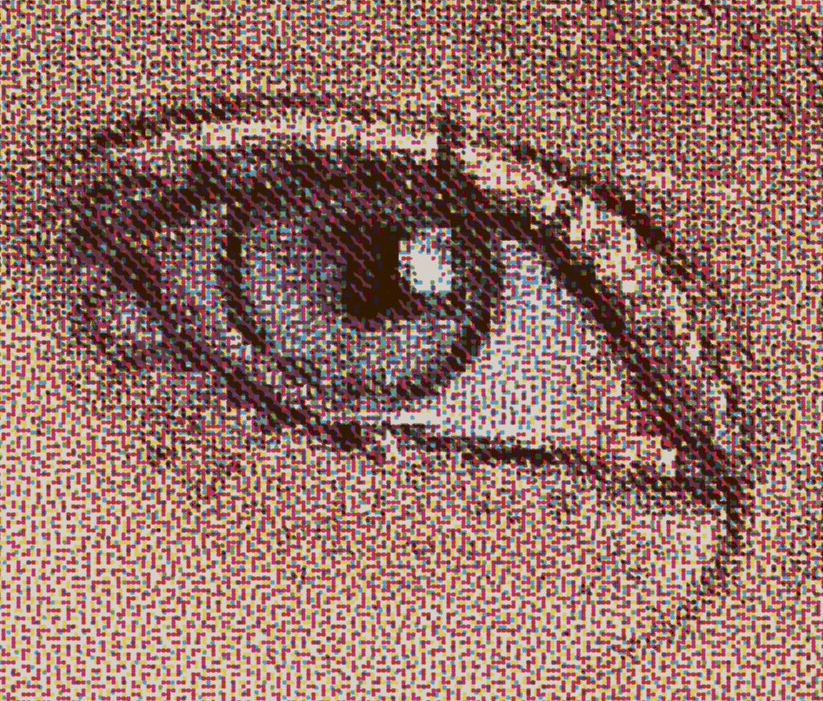

According to Settanni, Bellissima DMS has been an “unparalleled and transformative screening technology for flexo.” The software, developed by Hamillroad Software’s Andy Cave, delivers high-fidelity image reproduction while addressing highlights and fades. The solution’s lower dot gain translates to vivid detail and consistent color, and the product took home the Technical Innovation Award at the 2018 FTA Forum.

Settanni likened this screening technology to producing high-definition versus standard images. In addition, independent testing has realized 4.5-7.5% ink savings for flexo printing.

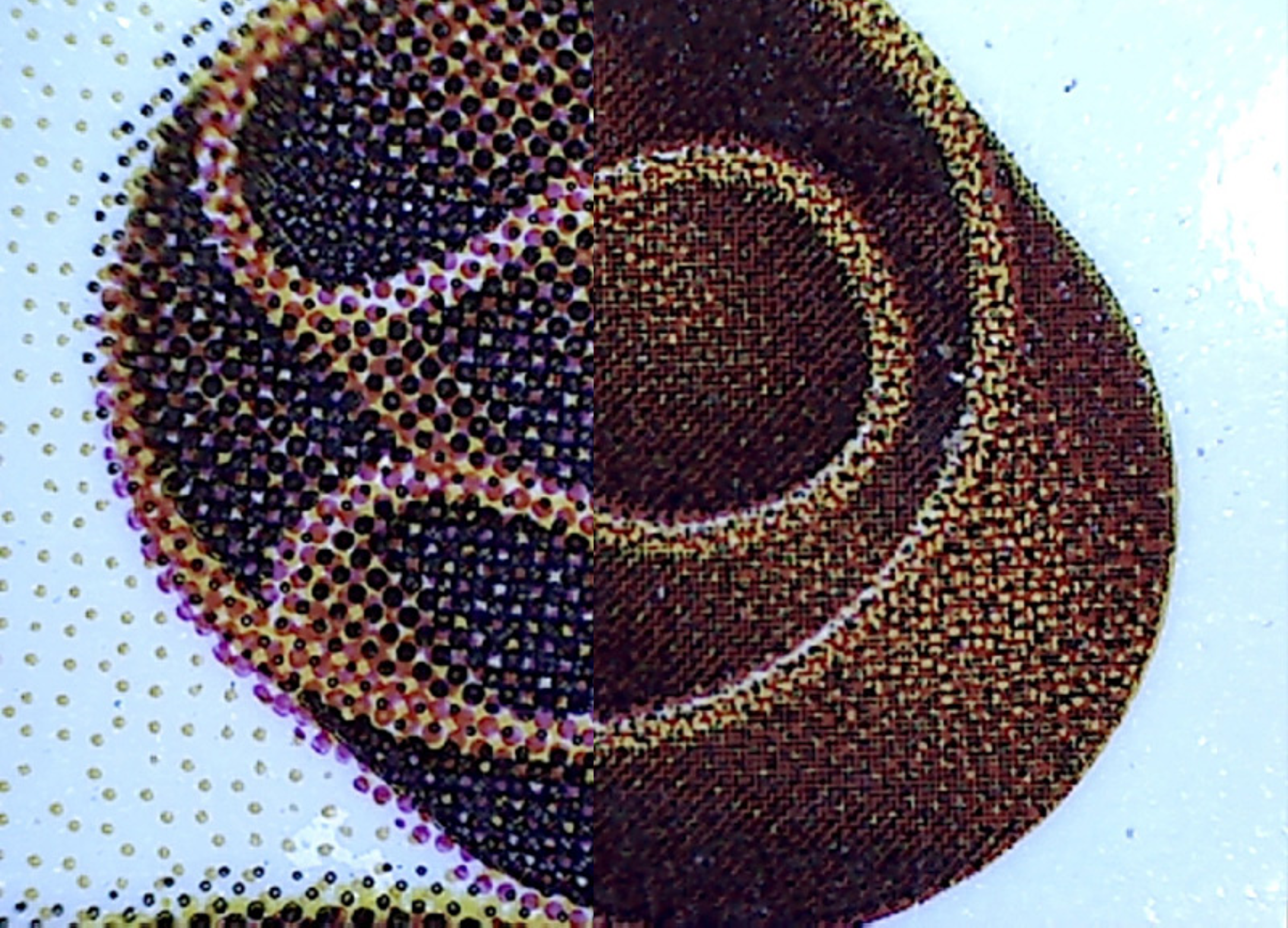

“Bellissima is the best use case for a stochastic screen for flexo that’s been made,” added MacDermid’s Brian Cook. “They thought about it a different way. In the highlight end, each color has its own randomized pattern, so the dots don’t print on top of each other. The dots are smaller and they’re able to capture detail more effectively.”

Cook noted, too, that MacDermid’s LUX plate technology has experienced excellent results with both Esko and Bellissima screens. MacDermid’s LUX ITP 60 flat-top dot technology doesn’t require extra steps and sees exposure times down to 8-10 minutes. The plates are inherently less affected by oxygen than round-top dot plates, resulting in a smaller printed dot.

“Generally, we’re at about a 1% bump, and that allows us to get more detail into the highlight,” said Cook.

3M sponsored the second day of the Technical Summit, which also included live demonstrations from Esko, Techkon, SpotOn, and MacDermid.

Read online at Label & Narrow Web: https://www.labelandnarrowweb.com/contents/view_online-exclusives/2019-08-21/apr-technical-summit-tackles-screening/