The Printer Perspective on Forum 2019’s “A Screening of Screening” Print Jobs

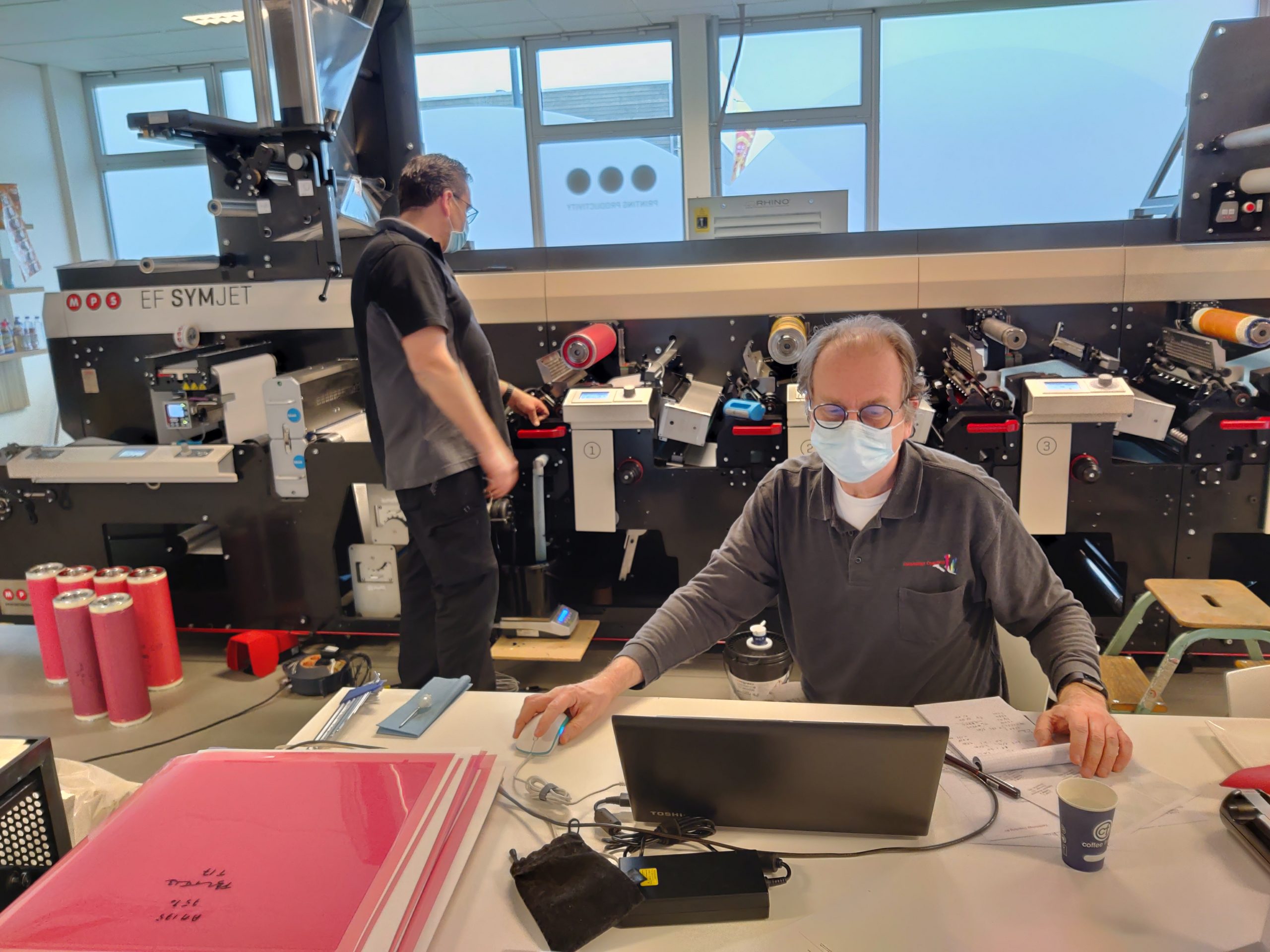

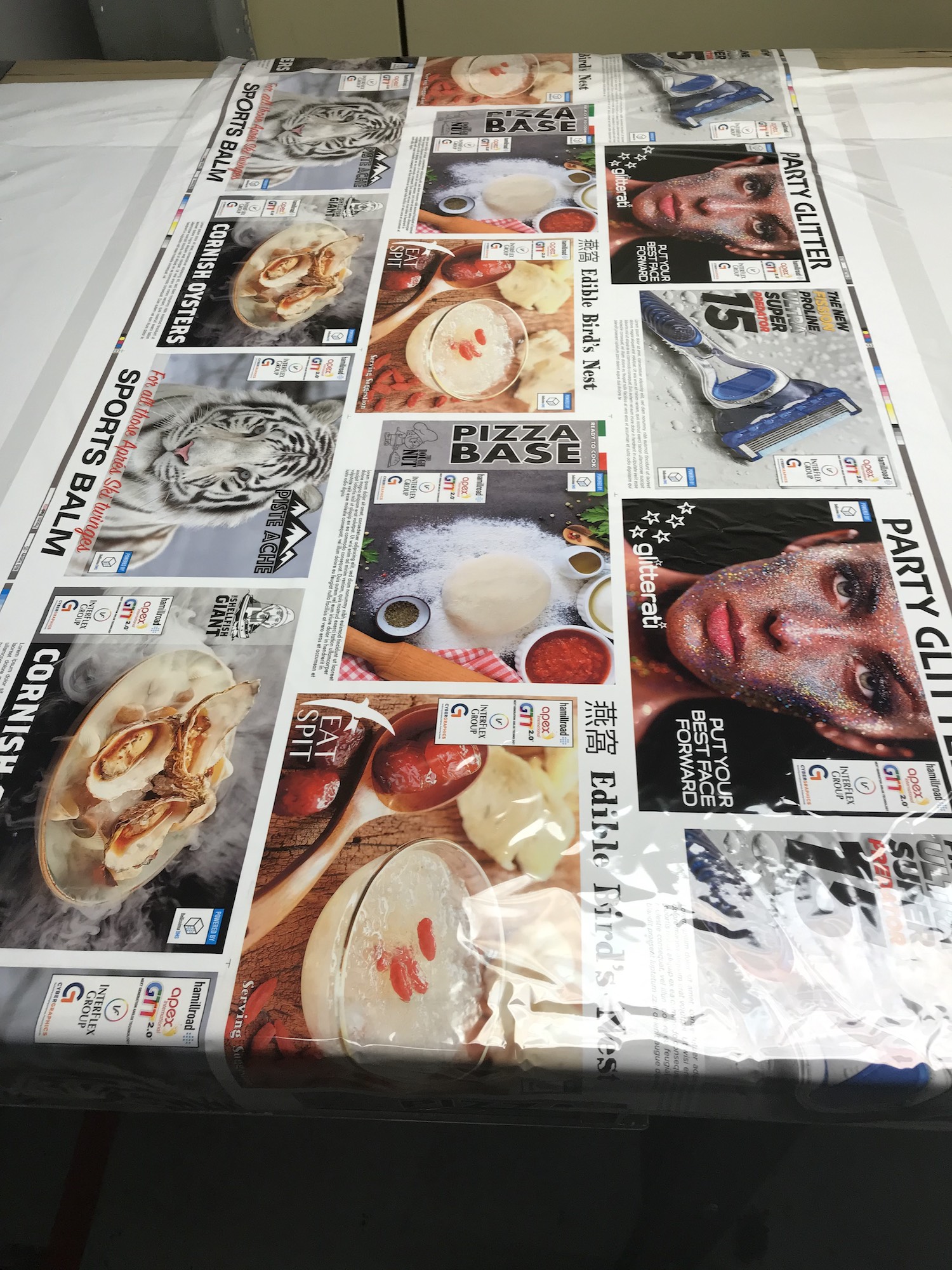

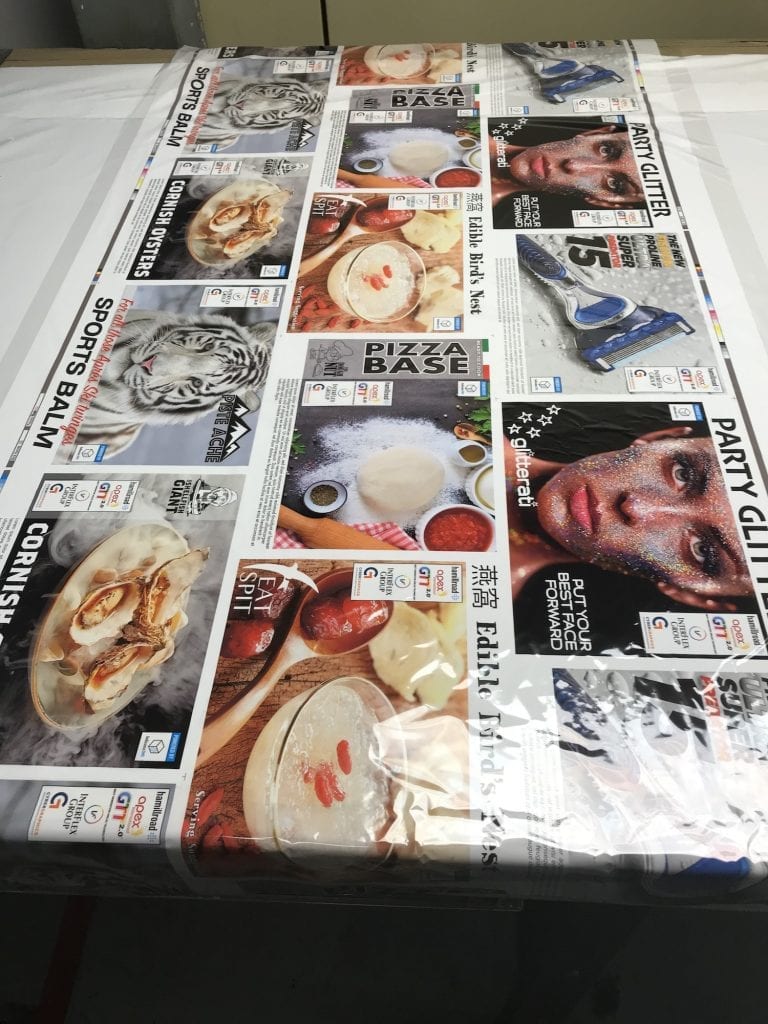

Three jobs, three consecutive days; same press, same crew, same ink, same substrate, same plate mounting tape—fair, consistent and equal conditions had to be maintained in readying each job for public peer review at FTA’s Forum 2019.

A daunting task? Perhaps for some. Interflex Group in Merrill, WI, presented with the potential assignment, answered affirmatively and emphatically: “Challenge accepted.” It wanted to learn. And learn it did. At project conclusion, the consensus of those involved: “Flexo wows all!”

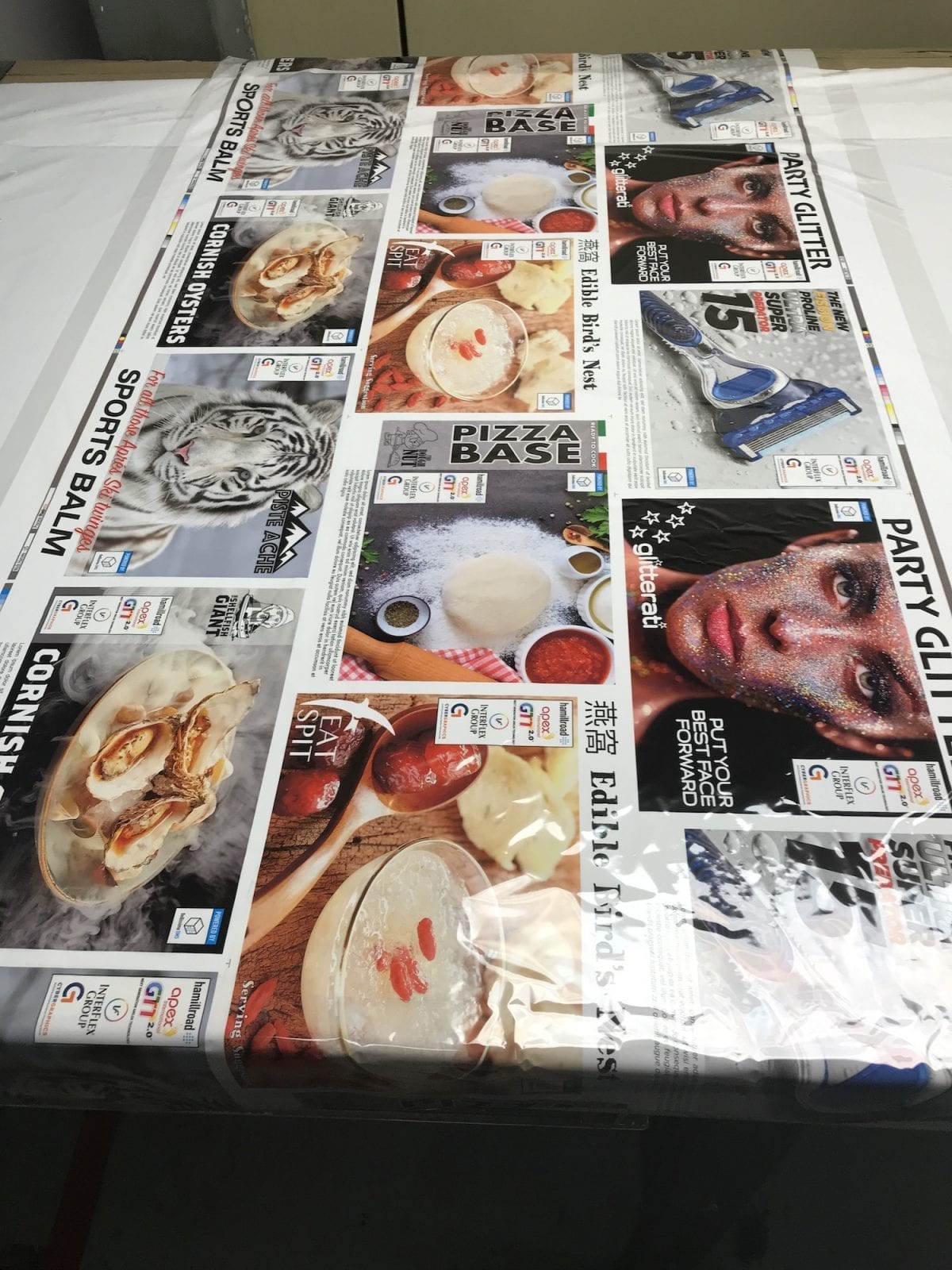

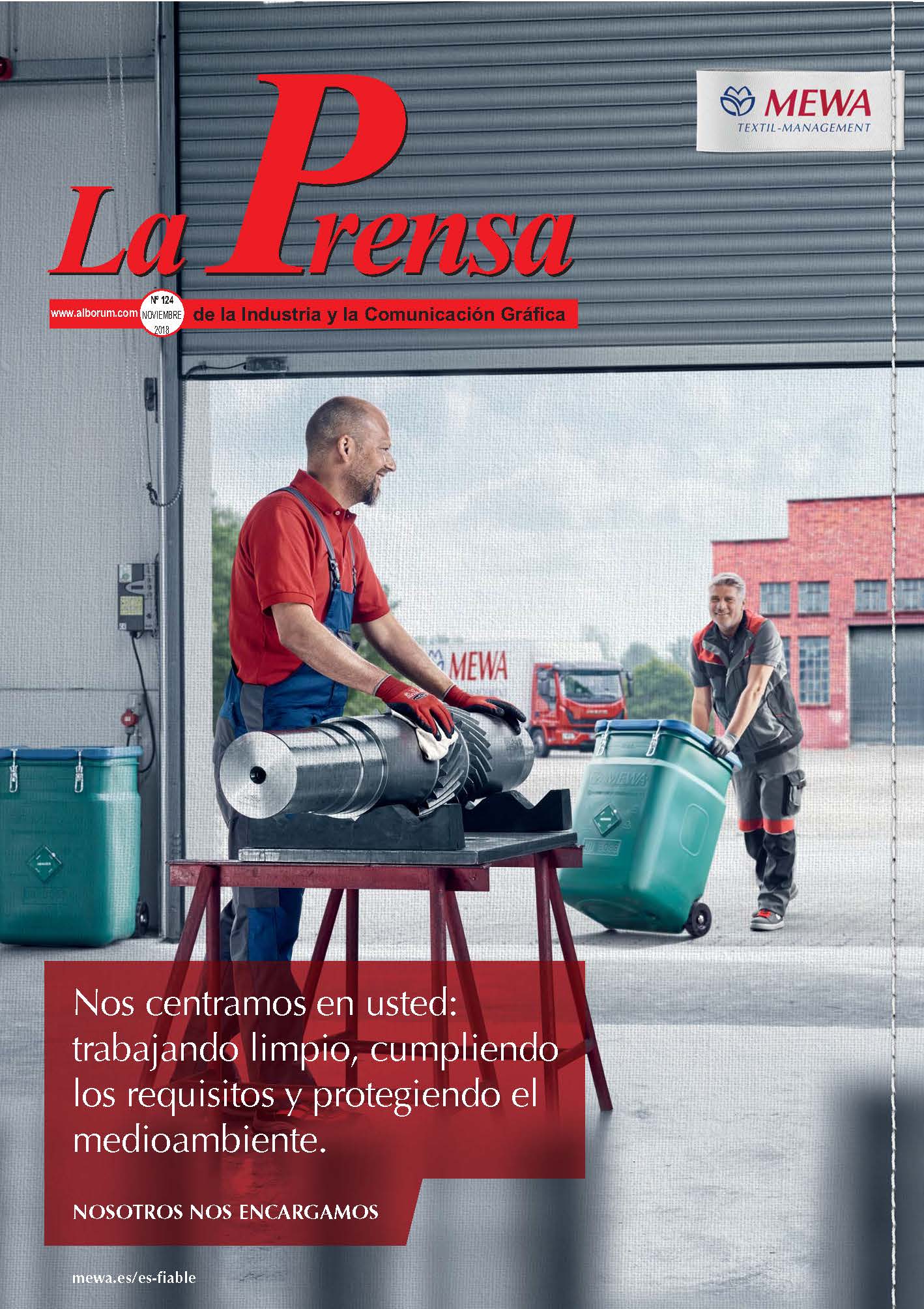

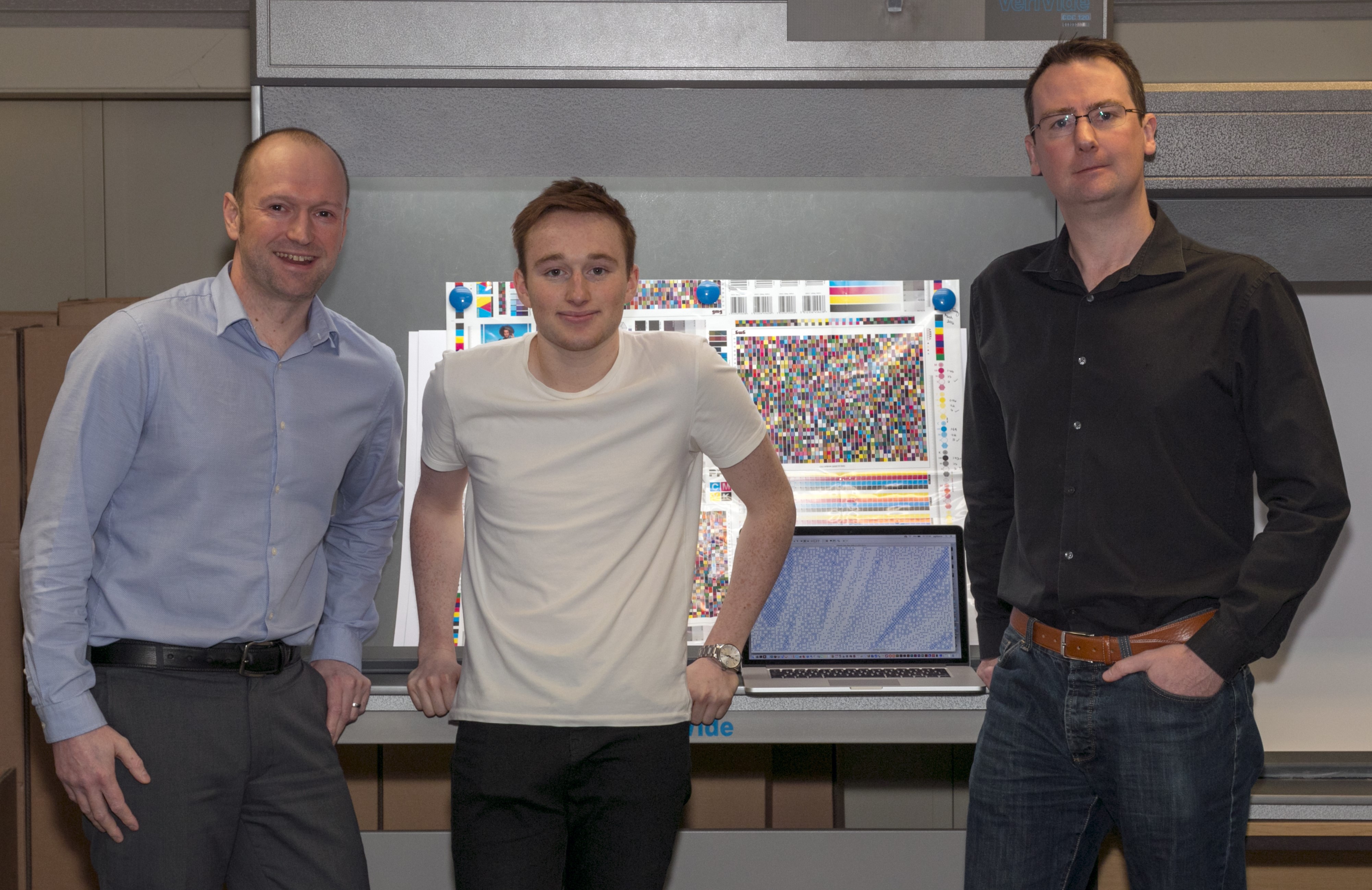

Interflex Group’s Bart Wright (left) and Kurt Krueger pose with a print sample from Forum 2019’s “A Screening of Screening” session. All photos courtesy of Interflex Group

Back in February, this proactive FTA printer member joined forces with three FTA supplier members, themselves assisted by a host of premedia member professionals, in demonstrating newfound capabilities.

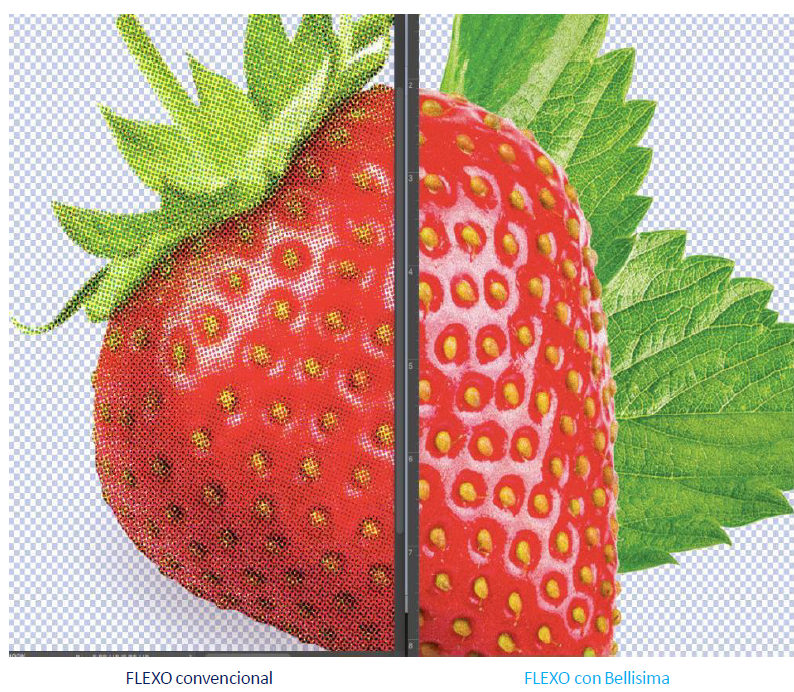

- The task: Showcasing modern-day prepress and screening technologies that position flexo to effectively compete with the likes of offset and gravure

- The firms: Esko, Hamillroad Software Ltd and Kodak (now known as Miraclon Corp)

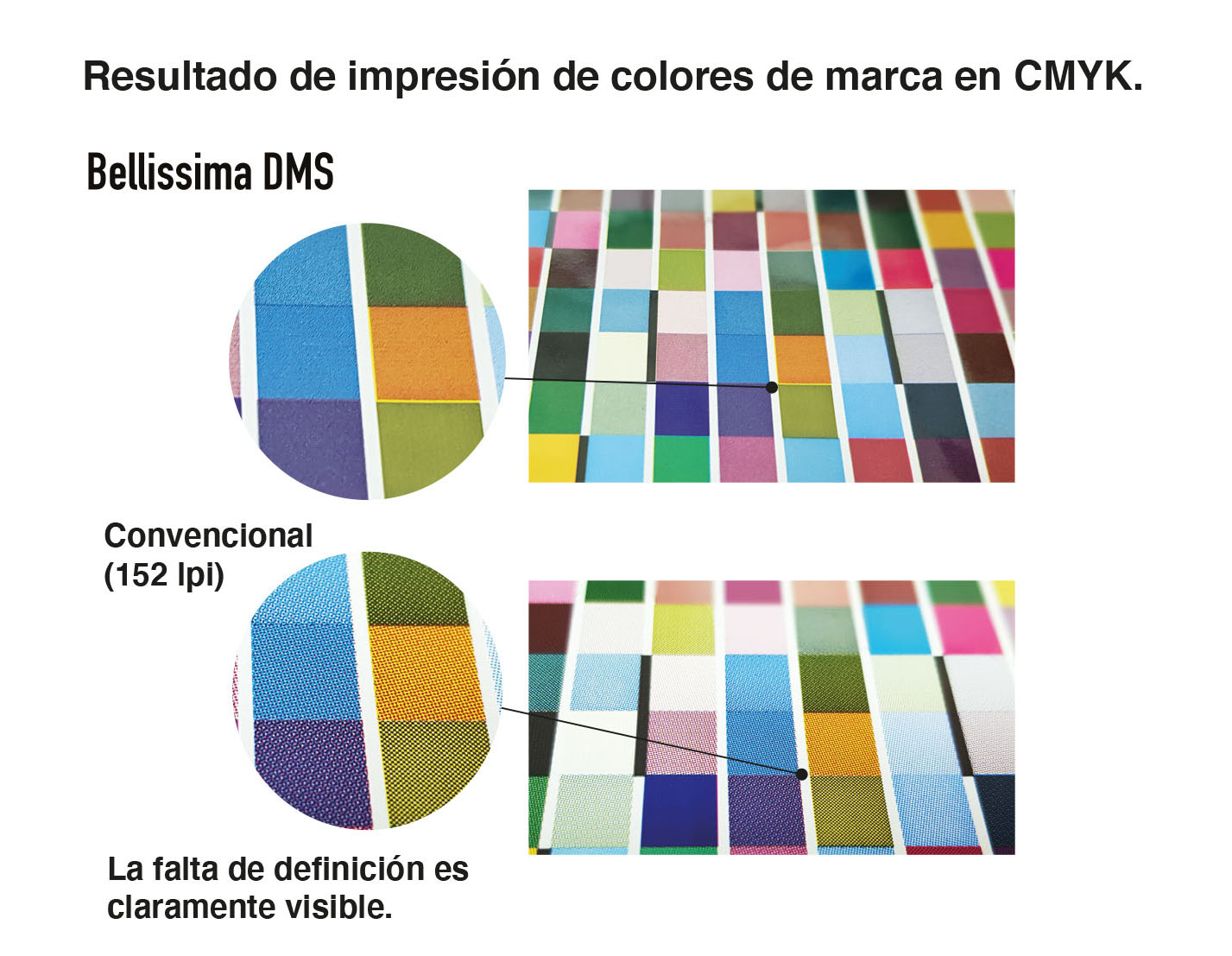

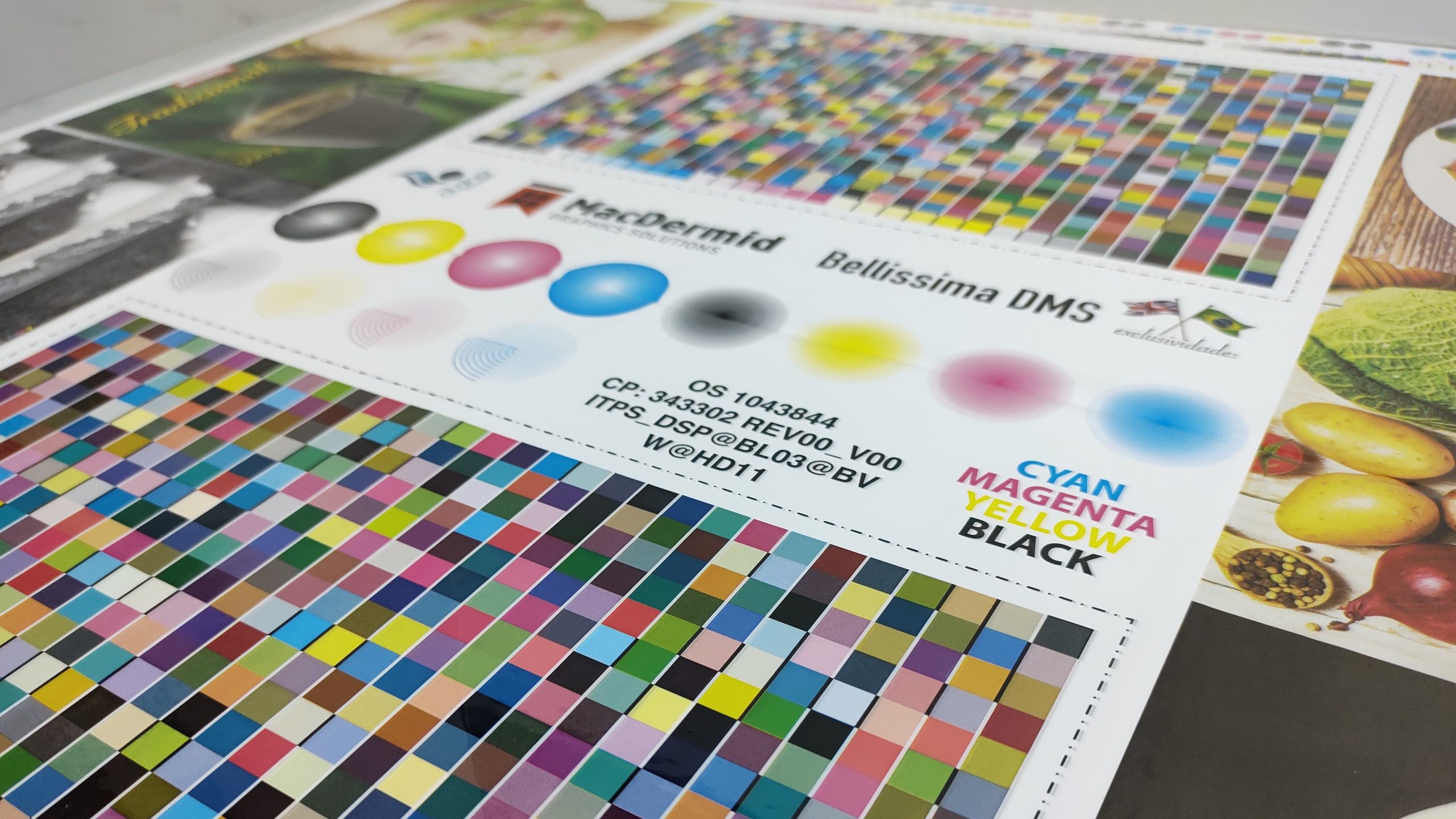

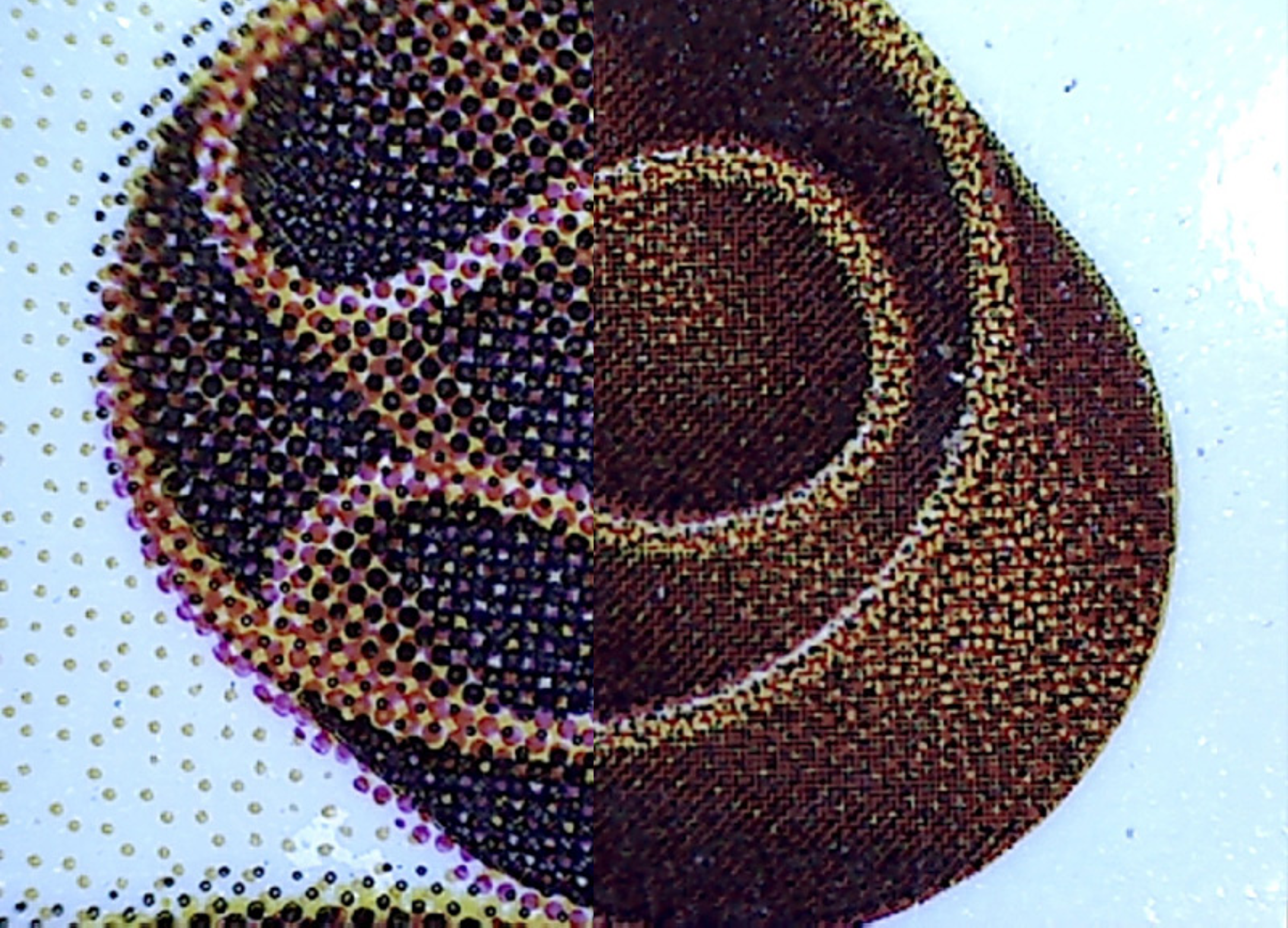

- The specific technologies: Print Control Wizard (PCW) powered by Crystal Screening, Bellissima DMS, Kodak Flexcel NX solution (respectively)

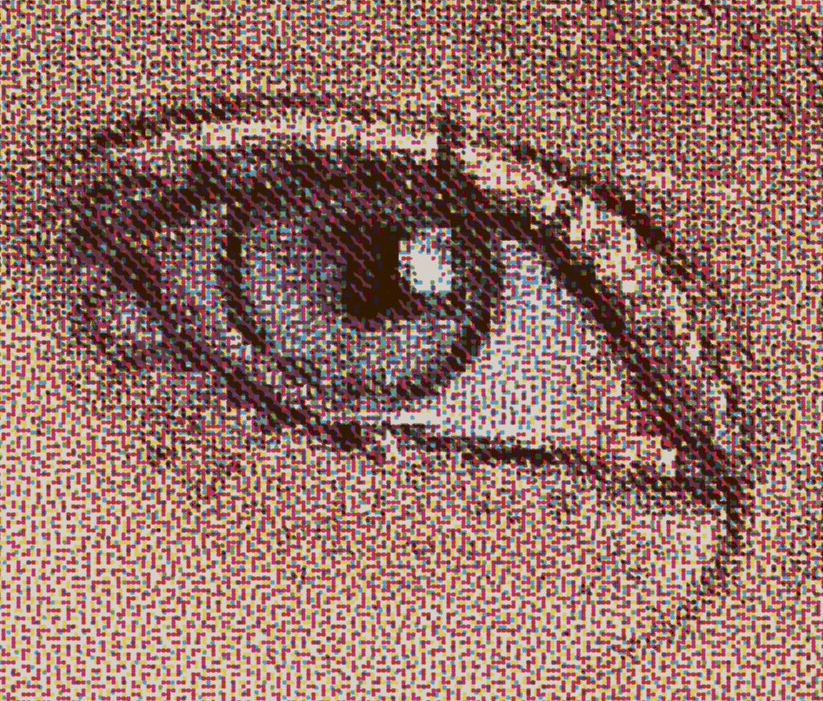

The multi-part demonstration project was the brainchild of Forum 2019 Session Chairs Dawn Connell, Krispy Kreme and Laura Wright, CSW Inc. In planning the session, dubbed “A Screening of Screening: Investigation into Prepress and Plate Advances,” the pair resolved to “introduce technologies, discuss printed results and demonstrate advancing capabilities of flexography.”

Their targeted audience: converters who would like to shift work from offset to flexo without loss. The thought, as expressed by Connell and Wright: “They’d be intrigued to help clients achieve the print quality results they aspire to.” What transpired before a live audience on Wednesday, May 8 lived up to the promise. What follows is a behind-the-scenes report from the printer perspective.

Serving as Interflex’s clients were the speakers selected for the session—Dr. John Anderson, Miraclon Corp, home of Kodak Flexcel Solutions; Andy Cave, Hamillroad Software, creator of Bellissima Digitally Modulated Screening (DMS); and Rory Marsoun, Esko, winner of a 2019 FTA Technical Innovation Award for PCW.

In-Plant Performance

For Interflex, some were familiar technologies; others were not.

Bart Wright, North American graphics director for Interflex, spearheaded the project at the plant. He also briefed Forum 2019 attendees on results, admitting that he—and some might say, his team—are avid “print geeks.”

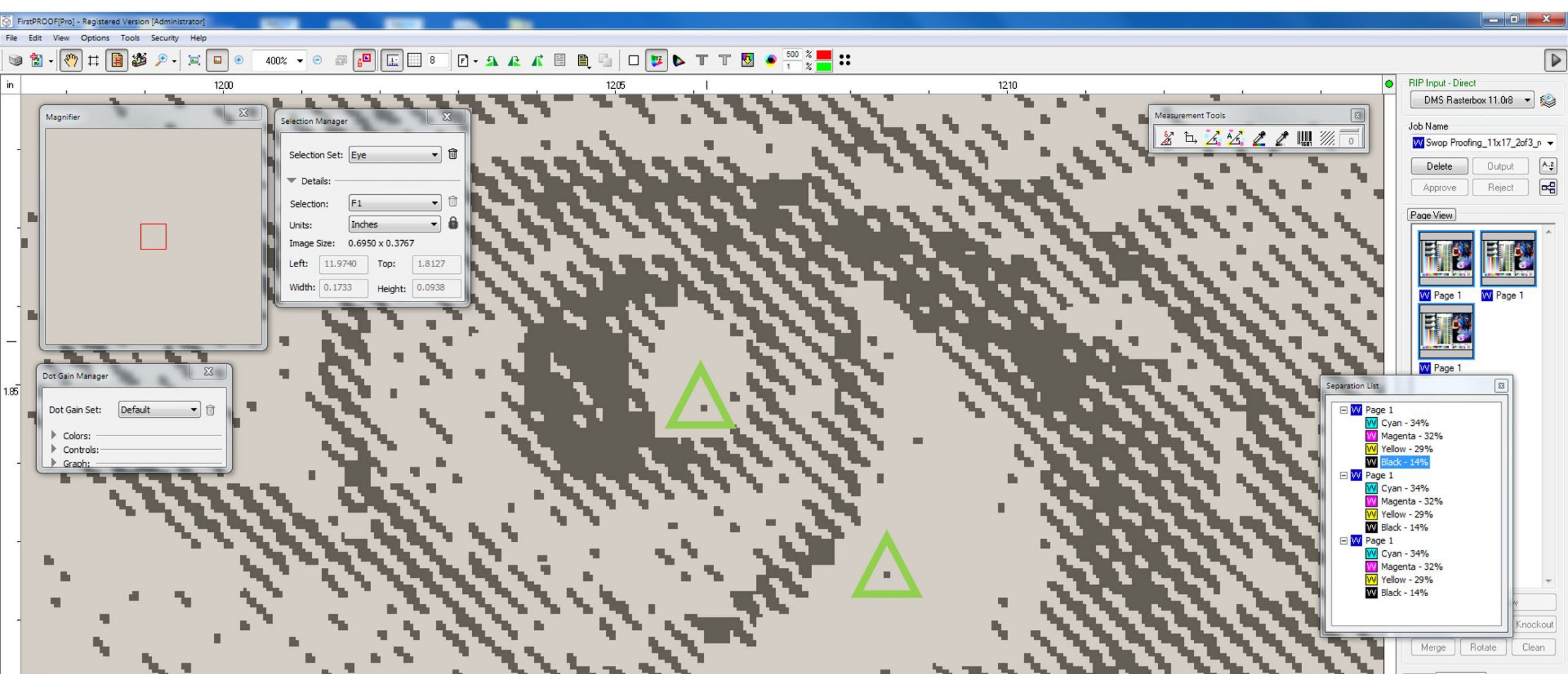

He acknowledged that at the outset, the team had run a lot of Kodak material and had been fingerprinted with Bellissima through Cyber Graphics. It had little experience with Esko and did some 1-color work prior to the test to establish a baseline and profile.

Detailing the equipment and materials involved, Wright listed the following:

- Press: Windmöller & Hölscher Miraflex, 10-color with Easy Set

- Ink: Siegwerk, 4-color process + white

- Operator: Kurt Krueger

- Plates: Kodak (Miraclon Corp) and MacDermid Graphics Solutions—tied to screening technology involved (MacDermid is standard with Bellissima)

- Mounting tape: 3M 1320 cushion tape

- Film: 48 gauge PET, corona treated. Typically used on reverse-print standup pouches, laminated to sealant web

- Job widths: Slightly different. Each two across, approximately 25-in. wide for full width (with slight variation)

- Reverse print

- Impressions: 5,000+

- Anilox change with technology: Apex International GTT is required for Bellissima, 1200s were used for Flexcel and PCW with Crystal

- New doctor blades at the start of the job

Wright noted, “There were some neat things entailed as well—bright colors, tight graphics, traps… nothing out of the ordinary.”

Asked what attracted Interflex to the project, he replied, “hands-on experience and interaction with industry executives that brings value to the production floor as pressroom efficiencies are pursued.”

Wright further explained, “Currently, Interflex’s philosophy, as a small mid-range company, is to find a way to compete with some of the bigger guys out there. We probably won’t beat them on price, but service and adoption of technology can certainly further our cause.” Presented with the opportunity to get involved with the demos, he explained, “Since we run a diversity of materials, we saw it as a perfect fit. We were excited to test all three and get a close look at [them].”

Elaborating on how it all worked out, Wright said, “By consistently following our standards and procedures, profiled separations came in the door. That helped make all three work. What we can do with flexo now proves and demonstrates the wow factor. We can do really nice work as an industry and compete with gravure.”

Talking directly to the experience, he reported, “The press team learned a lot. Benefits accrued in terms of both experience and knowledge. We tried to get them involved in asking questions, and going hands on with technology.”

Wright continued, “One of our best teams did the work. Being that they don’t get out a lot, to have industry come in—Tom Kowalski of Miraclon Corp, Joe Settanni from Apex International (representing Hamillroad), and Marsoun—and gain such experience through interaction broadens their knowledge of what they are doing, what they want to do and where they are going.”

Turning his thoughts to the jobs themselves, the graphics director said, “Everything went really great. Everything pulled up quick. Everything looks great. Everybody’s stuff looks amazing. The ‘one a day’ setup plan went well. We put a job in, pulled it right up.” His succinct assessment of the outcome, “No real issues. No technology showed any signs of trashing up or not wanting to print clean. Highlights and shadows look great. Good solid ink density with minimum dot gain. The output looks better than the proofs!”

Addressing the technologies, Wright stated, “They’re relatively simple to learn. Some investment in hardware might be required. Good anilox rolls are needed.” To other printers, he said, “Good tools and equipment, combined with standardization of procedures—profile setup and confirmation of fingerprint—will bring you right in and ready to use the technology. At Interflex Group, we are using all three technologies on a commercial basis with success. The winner is flexo!”

Clients & Comments

Dr. Anderson noted, “On first viewing, the job is appealing to the eye. Colors are vibrant, no hard edges, clean reverses, minimal bridging, good gray balance, excellent trapping, excellent registration, excellent opacity, consistent highlights, stable dots, excellent tonal reproduction and resolution was achieved.”

He declared, “Flexo can consistently deliver the brand owner’s requirements daily,” then he thanked collaborators on his firm’s piece—Kirk, Task (these two related firms engage in plate making and package design), Simplot Australia (a CPC) and Splash Graphics.

For the record, the job contained Kodak hybrid screening with dot support applied to images that were selected for fine details and color range; plus surface texture Digicap NX Advanced Edge Definition AM screening FM screening Hyperflex NX2.

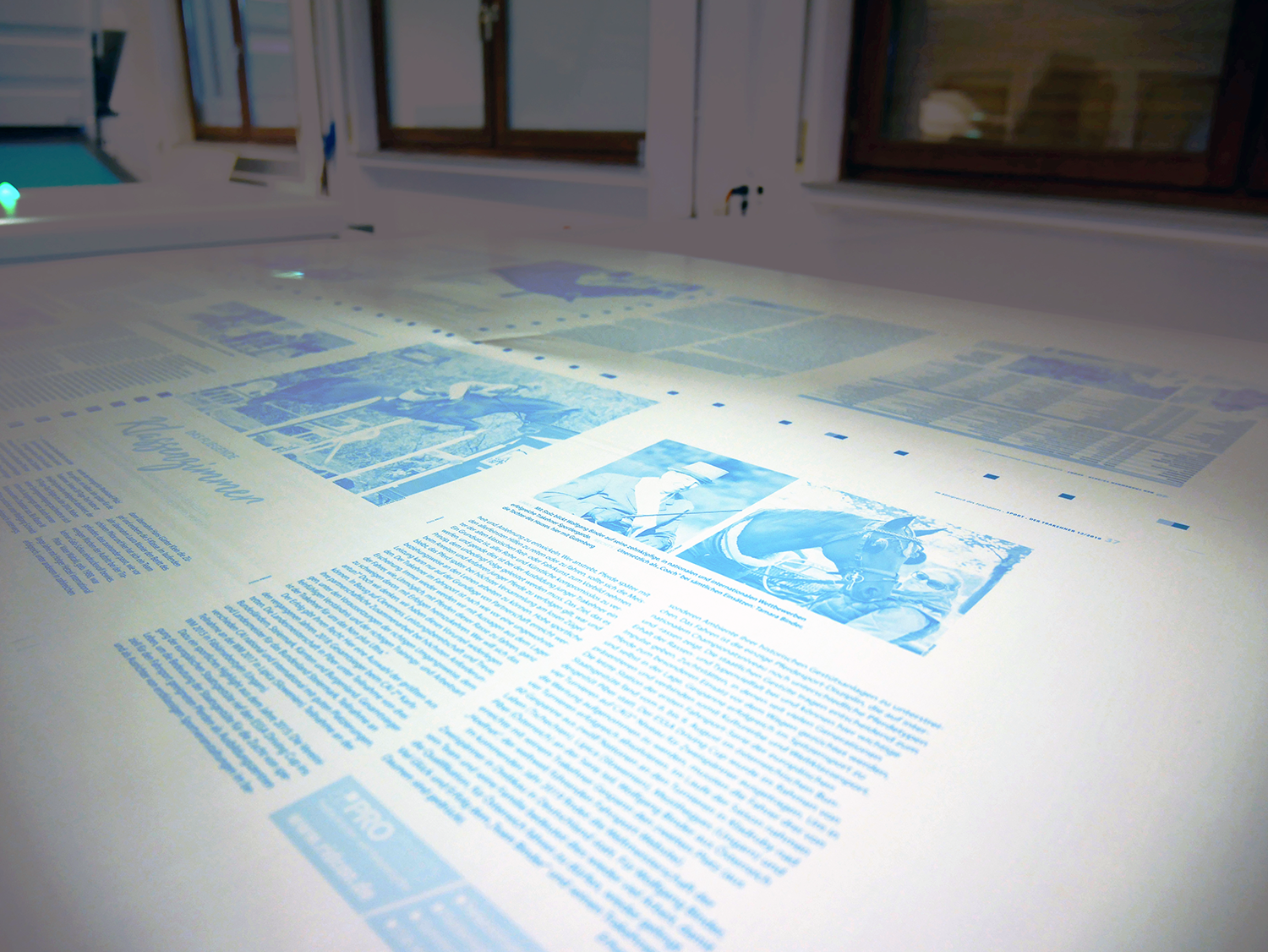

Cave boasted, “No change from first pull to the last at a speed of 800 fpm.” He noted, “Image fidelity was maintained, as were smooth tints with no color shifts or misregistration.” He too thanked project supporters: Apex International, PEI Graphics, Cyber Graphics and MacDermid Graphics Solutions. The job incorporated conventional AM and XM screens, plus Bellissima standard and eXtended.

Marsoun concurred with the rest. “Results improve solid ink density and laydown, as well as white opacity and smoothness. The job printed with minimum dot gain, cleaner screens and smooth fades to zero. We were able to automate and standardize screening and curve optimization to make for a more efficient pressroom.”

The job included split images, some Esko legacy screening and some Crystal Screens. It also incorporated curve optimization, highlight screens, support dots and highlight dots. No retouching to images was applied.

New Standard?

Summing it all up, Wright tackled a question from FLEXO Magazine. “What can it do for a product?”

His answer was both detailed and forward thinking. “All technologies vastly improve drop shadows, fades, screening and minimum dot. Each technology also helps with increased processing capacity and saturation. Each works as a next step in enhancing a printer’s competitive posture.” The Interflex team’s conclusion: State-of-the-art surface screening packages and/or prepress systems incorporating screening and plating are, “absolutely the next step in flexo. They will become standard practice.”