How does the ideal printing company of tomorrow actually look like?

This is of course a speculative article and some of you may think that I have got a stroke due to the hot weather – however, the reason why I wanted to write this is mainly because most printing companies today are not in a position where you can start from scratch and just invest in an “ideal” 🙂

By Morten Reitoft · Editor INKISH.TV

First of all, this is a crazy thing to suggest because the setup, of course, will vary depending on applications, customers, size, volume and many other things. The reason I decided to write this anyway is that it could be interesting to see how setup could be and what kind of applications this setup would be able to produce.

First of all, we anticipate that we already got customers and employees. Any printing company is obviously worthless in case these things are not in place – that said I believe it’s truly important to emphasize on skills, education, incentives and work environment. This is sometimes forgotten when companies are struggling. To have well-motivated staff is probably one of the major important things to be successful and how to do this – well, let’s talk about that in a future article.

Before producing anything we would need files. The files can be delivered to our ideal printing company in practically anyway – channels. I believe we still from time to time receive USB sticks, CD’s, DVD’s and other physical media. I also think a lot of you get files per email, WeTransfers, DropBoxes and other file/cloud-based services and you will also get files from your web-to-print solution. Your web-to-print solution can handle both files based on upload of files but also using templates. Even print files based on order-based components (i.e., documentation, customer-specific variables etc.) can be delivered to our workflow.

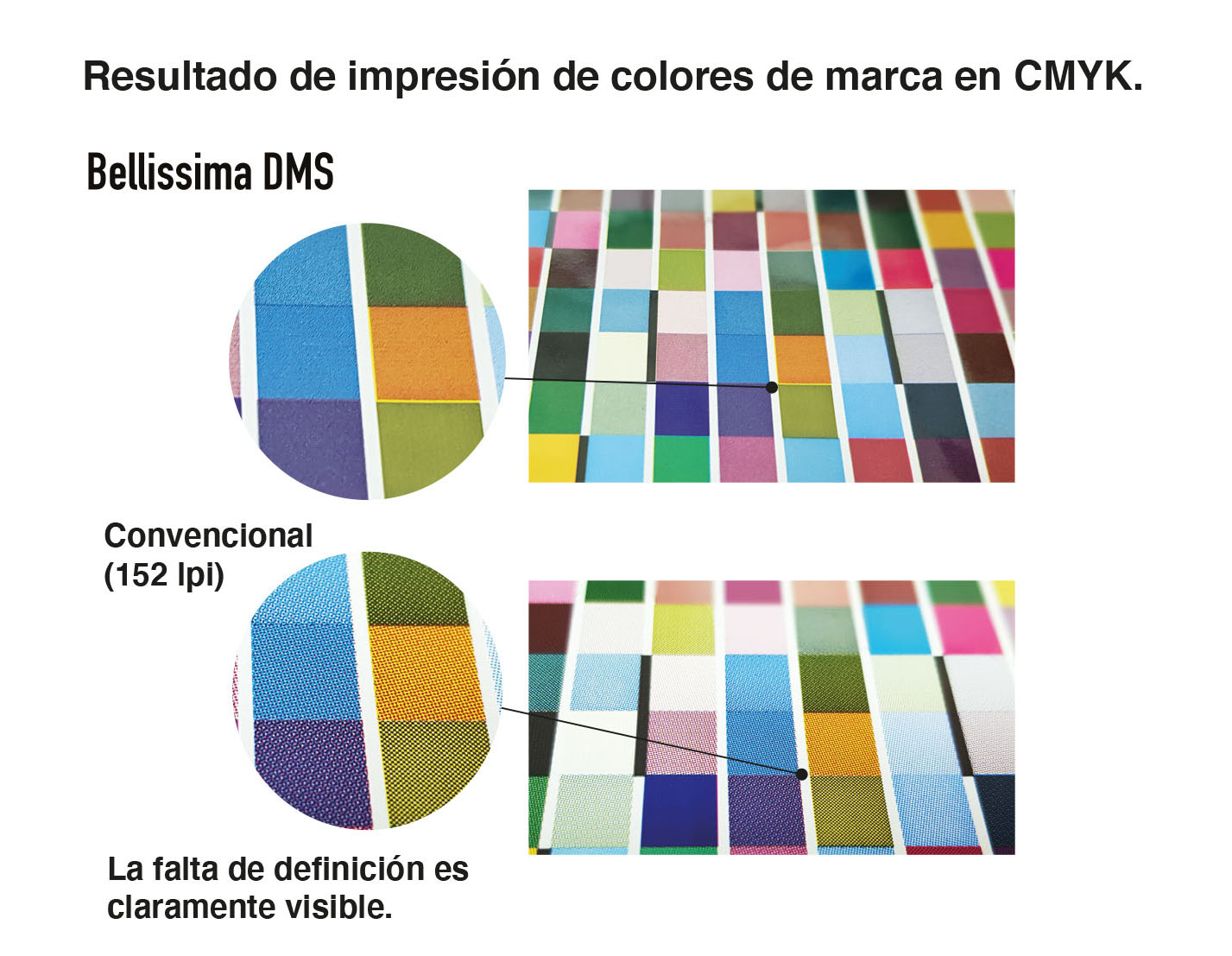

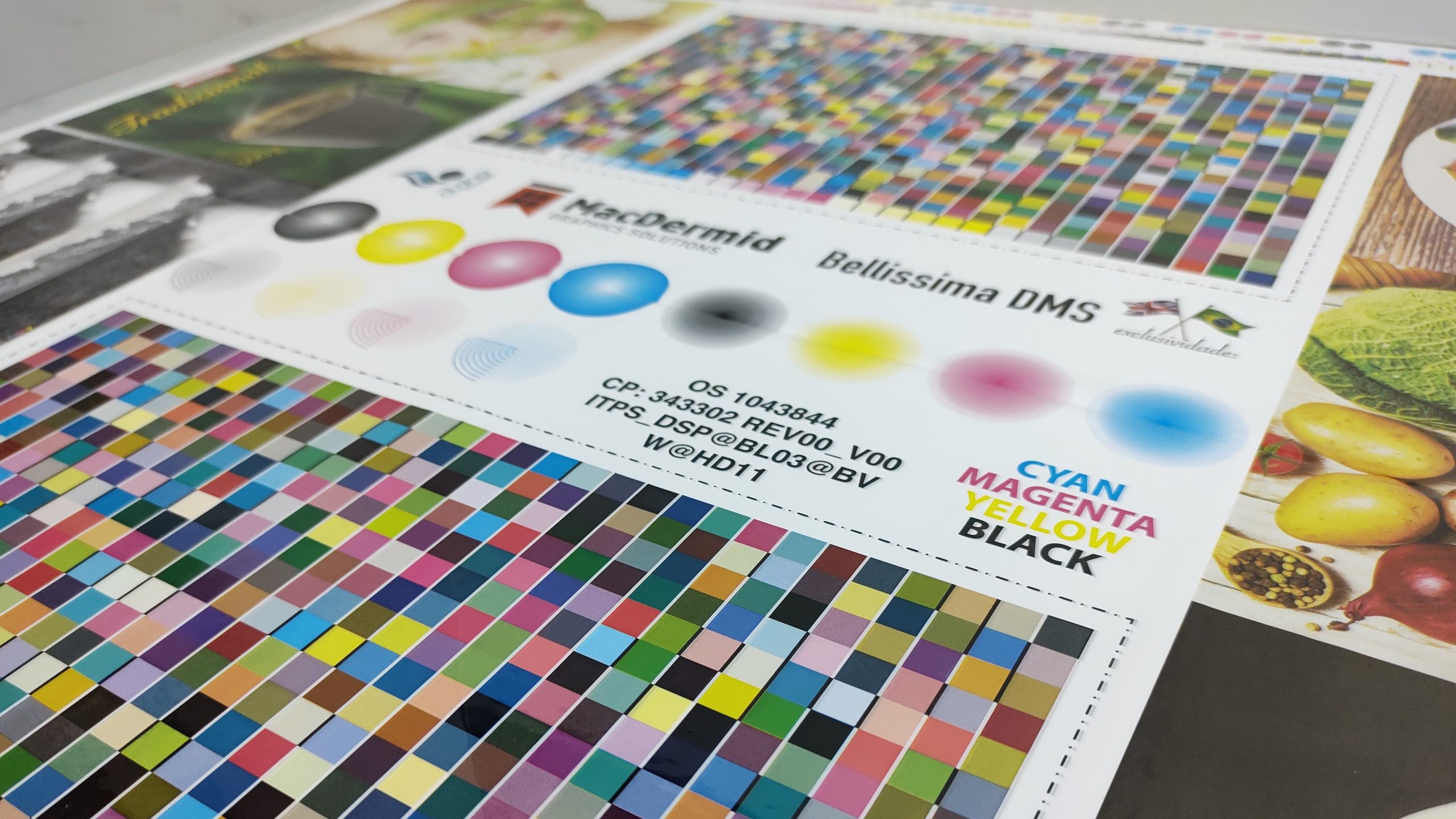

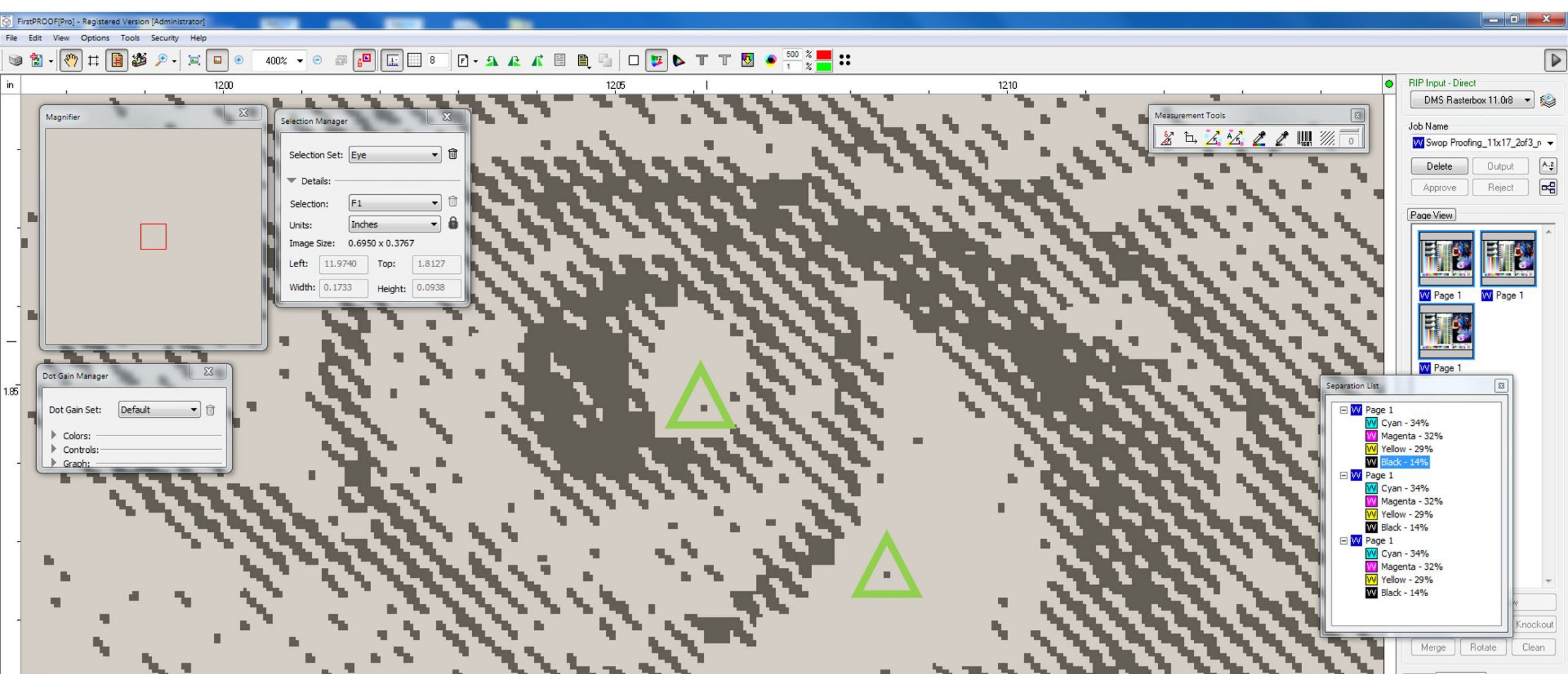

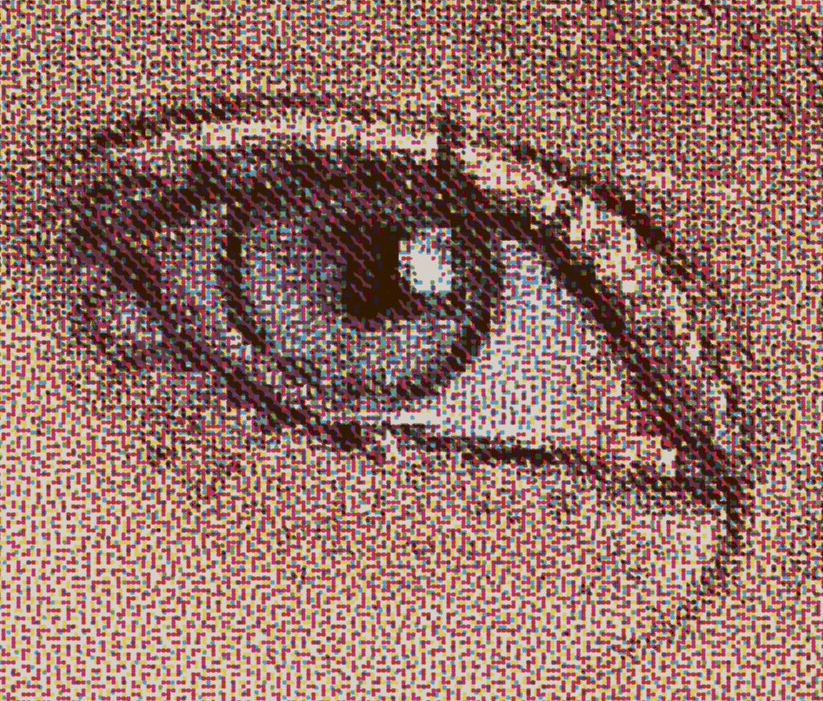

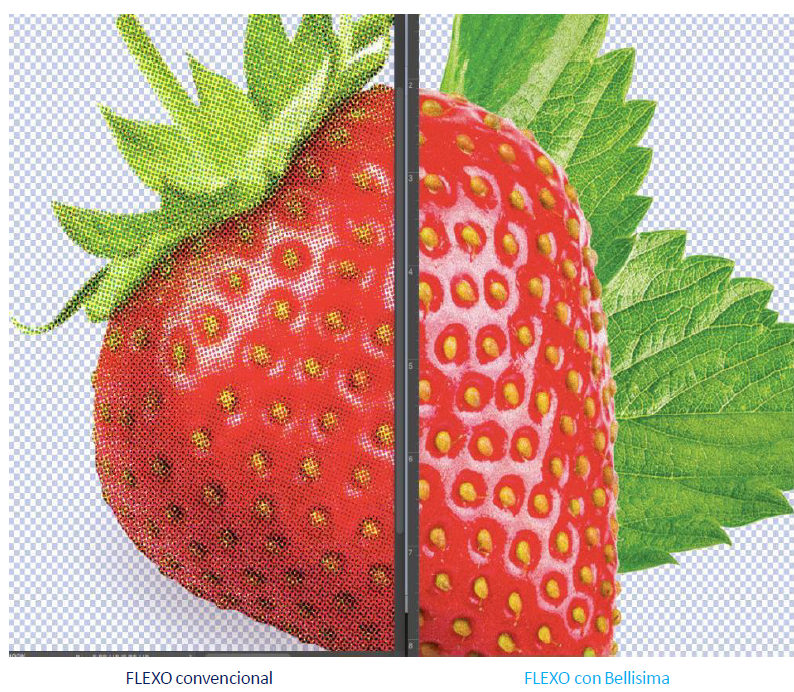

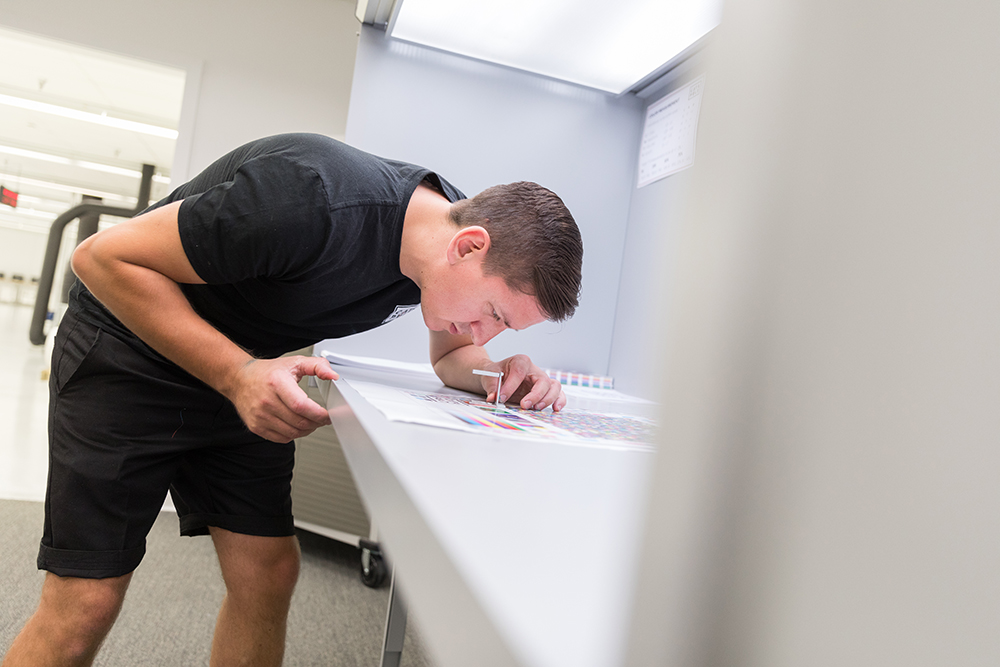

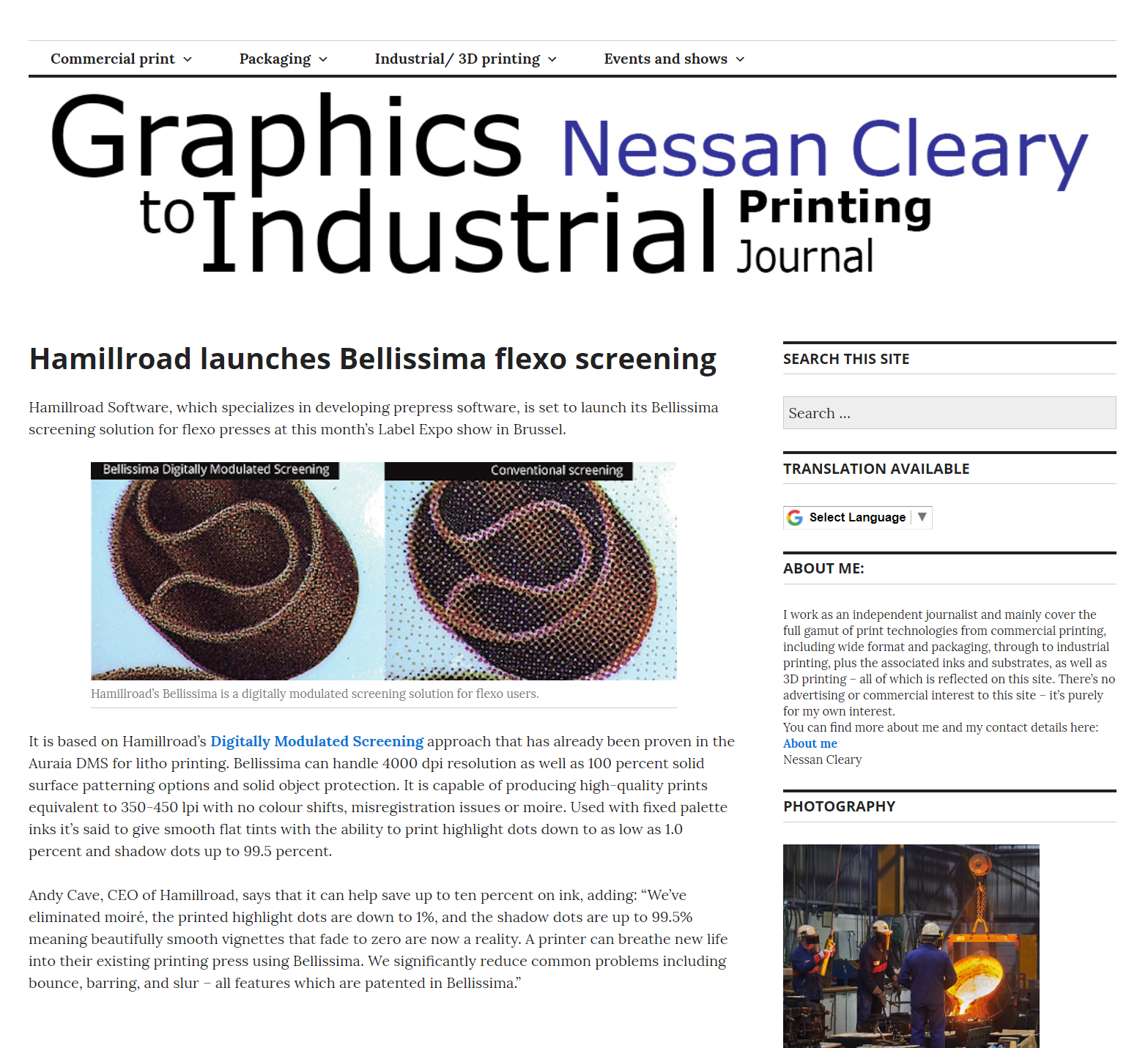

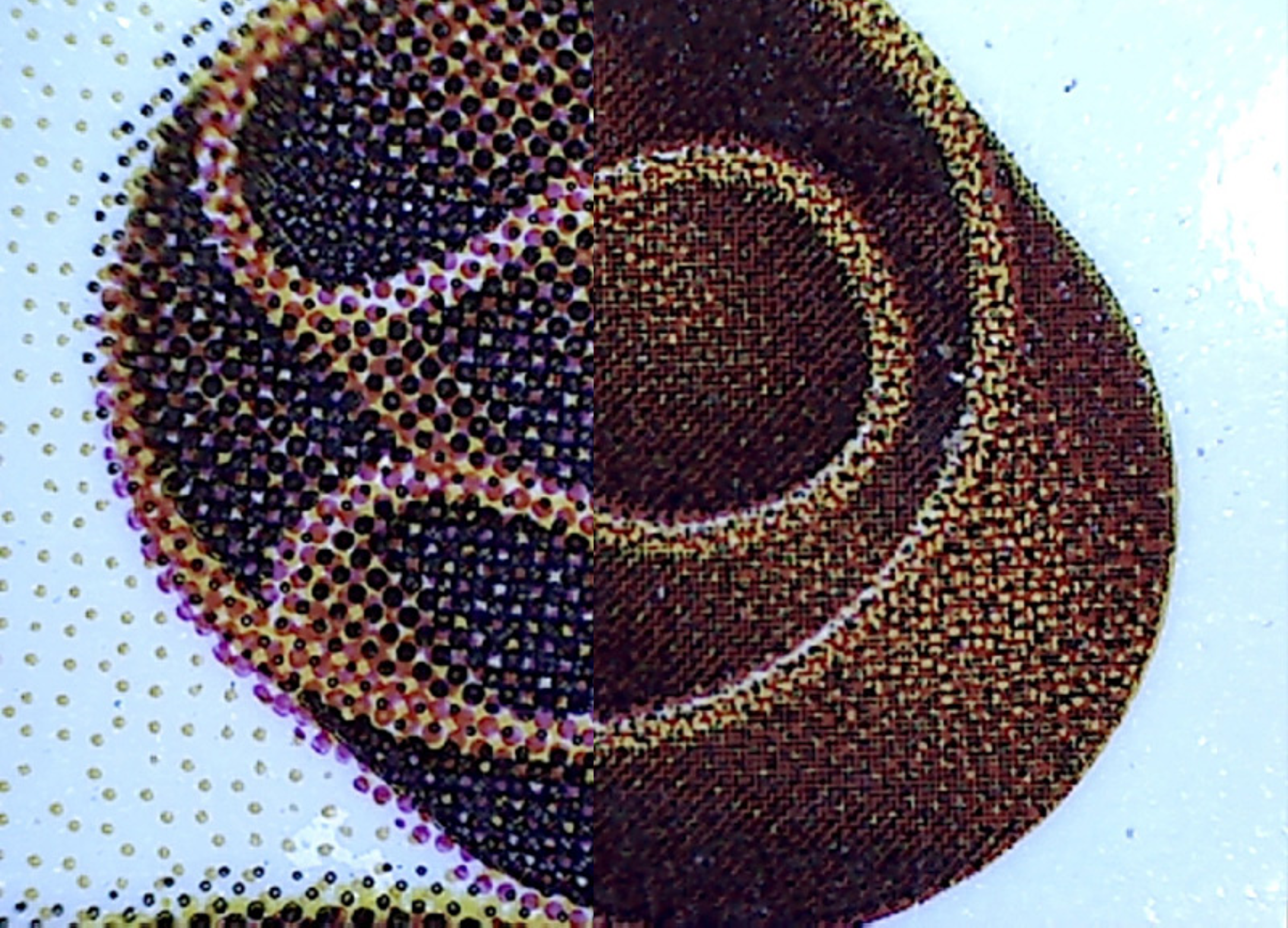

Files are received and handled in an Enfocus Switch solution that will process the files, create job-tickets and even manage color-workflows. Color Management is aligned with ISO 12647 and color corrections to jobs are done before the press (of course). To create ultimate quality I would also use Hamillroad Auraia for my screening – not sure about the implications at this stage – but the quality I have seen is just awesome!

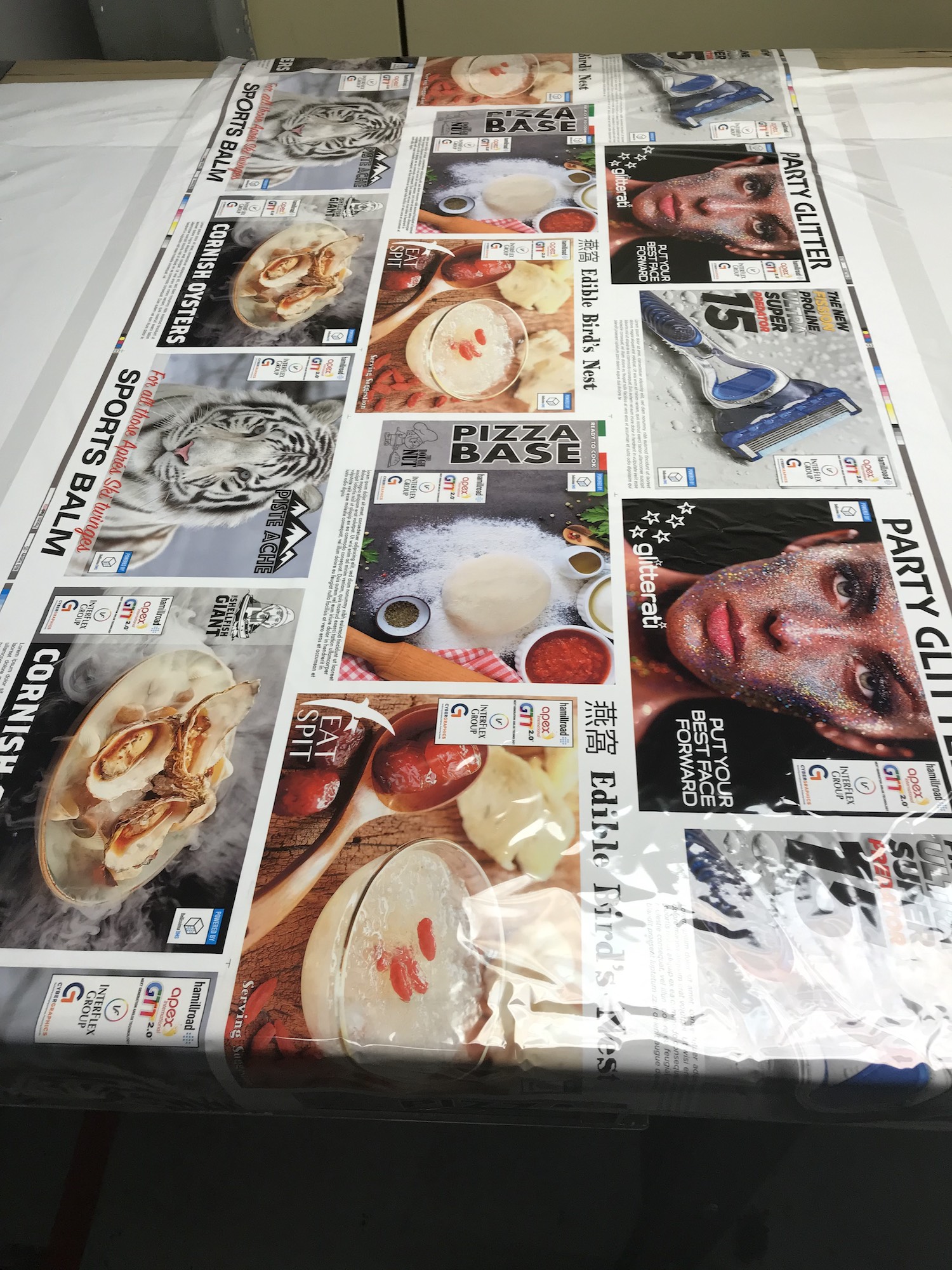

Using Tilia Labs Phoenix handle all imposition for both large-format, digital sheet and offset returning data for accurate cost calculations. The ERP system is custom made in order to accommodate all the needs our unique printing company have – this is controversial since it cost a lot of money but in my opinion most ERP/MIS systems are focusing more on the financial parts rather than the UI and the support for Sales, which in our company is the essential focus. Everything in the company is focusing on the customer and ability to do last-minute decisions. The ERP/MIS system calculate prices based on user-history, and capacity available on the requested date for production. This doesn’t mean that the customer can’t have agreed on prices in advance, but more a question to evaluate profit potential in relation to the equipment available. Prices in the public web-store-front are using automated calculation regimes based on time, variables, delivery place, time and history – similar to how airlines are operating. As far as I know no web-to-print solution today offer this flexibility.

All projects are ganged automatically and with Tilia Labs Phoenix our printing company can offer up-to-the-minute changes and choice of production equipment according to capacity.

The company offer both digital and offset capabilities, and for digital, the focus is on delivering a quality similar to the offset press. This means that the print is ink-jet based in a format that can use same binding equipment easily as the offset press. The offset press is a LED-UV equipped printing machine – probably a Komori or a König & Bauer – and of course equipped with flying plate change to ensure fast and efficient operation. I am not sure, but I find that both Komori and König & Bauer are more focused on the advantages of UV over Heidelberg – but to me it’s also bad that Heidelberg after its huge crisis to some extent have decided not to participate in the events that I believe support the future of the printing industry like Print18 and local events. Free-wheelers I am not so fond of!

For the digital its really difficult, since the obvious choice could be an HP T-series, however, I am not so happy with reel-based printing. I need the flexibility and the wide use and fast change of various substrates, so maybe a Konica-Minolta KM-1 – it has a great output, a great format and is sheet based – so that could be a choice.

For binding, I would like to have the best and if production ends up being reel-based anyway, of course, Hunkeler is the obvious choice – however, for cut-sheet, I need to have a lot of equipment since I expect over the next years to need as much flexibility as possible. Horizon could be a good choice, however, this is where I would need a lot of input.

I would for sure need to have both saddle stitch as well as perfect binding in-house and a small hardcover line from Colbus would be GREAT.

On the embellishment side I would choose Argos Solutions – not only do they deliver a high and consistent quality, but they also use a small amount of UV which is good and a cost-saver. Since they both deliver relative cheap models for UV-coatings and also for spot-UV’s I believe I can get more capacity in a high quality for the same price of the more expensive alternatives.

For refined jobs it could be great to have some kind of laser-cutter i.e. the Motion Cutter – however, this I am not sure about. In the bindery, I would for sure choose to have Scissor Hands on my side.

For paper- and substrates, in general, I would like my company to work closely with PaperSpecs and FoldFactory in order to educate my team to offer exclusive products. The commodity is no fun unless money is the only issue. To be specialized would be great and fun – and challenging at the same time.

I would probably also invest in some old Heidelberg Cylinders, but I would for sure also invest in gilding, side edge painting and a lot of the old almost forgotten technologies. Part of my offerings would be letterpress and my ideal printing company could be a supplier to a limited but exclusive audience.

Well – dreams are fun and whether this printing company could ever exist is only something that I can dream of as well, but it was fun. For the brands mentioned – these are some of the options I know of – so this was not supposed to endorse any of these, but more to put specific ideas in your head for inspiration or a cheap laugh – but comment below so we can get other perspectives on the “perfect” printing company!

Original post on Linkedin: https://www.linkedin.com/pulse/how-does-ideal-printing-company-tomorrow-actually-look-reitoft/