Bellissima DMS – the difference a dot makes

Flexographic printing has historically been considered to be the poor cousin of offset and gravure; while they enjoyed the glamourous and heady heights of high-quality printed books, art, and wine labels, flexo was used for stamping patterns onto bags, corrugated boxes, simple labels, and wallpaper.

Over time, flexo plate-making moved from film-to-plate to direct-to-plate, but this change brought an unintended consequence: dots became round-topped rather than flat-topped due to the loss of the oxygen inhibiting film which is inherent only with film-to-plate.

MacDermid Graphics Solutions were the first to address this phenomenon with their LUX® laminate, followed by their ITP™ (‘In The Plate’) technology, which solved the problems of oxygen exposure by effectively putting a ‘film layer’ over the plate. Their unique technology generated polymer plates with flat-top dots, and the screening of smaller halftone dots too became possible.

Bellissima Digitally Modulated Screening (DMS) is imaged at 4000 dpi and requires the use of flat-top dot plates.

The combination of these complementary technologies now facilitates the delivery of ultra-High-Definition flexo print of 300-450 lpi on press across narrow web labels and wide web flexibles.

Which screen is right for me?

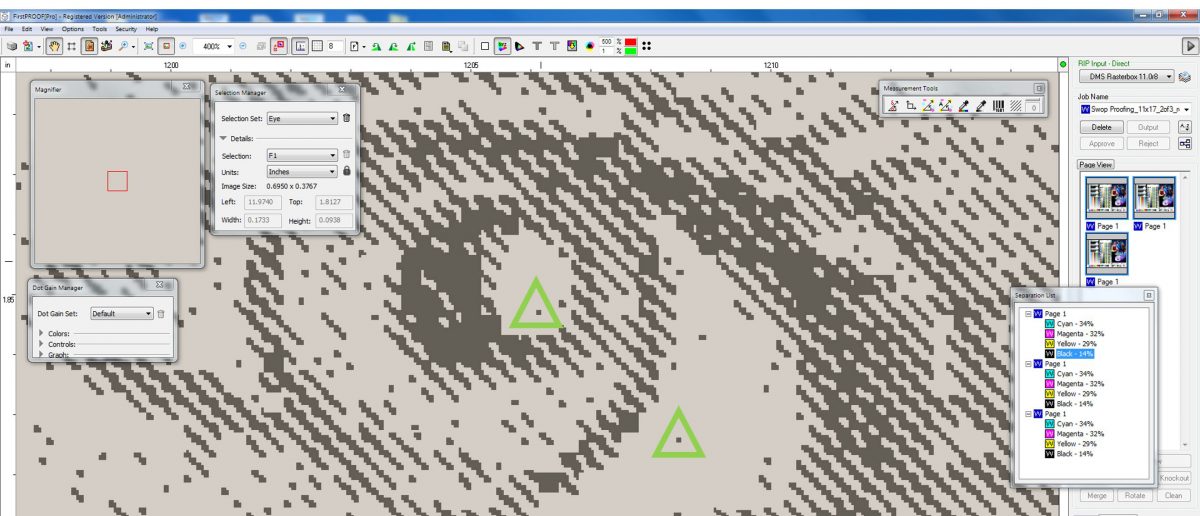

Bellissima is a set of Digitally Modulated Screens (DMS) developed and optimized explicitly for flexography. These screens are imaged at 4,000 dpi and provide a high level of image reproduction (greater than 300 lpi equivalent), which is screening and content moiré free. Bellissima mitigates typical printing and press issues such as dot bridging, dot rivering, barring, bounce and slur, making Bellissima very stable on plate and press.

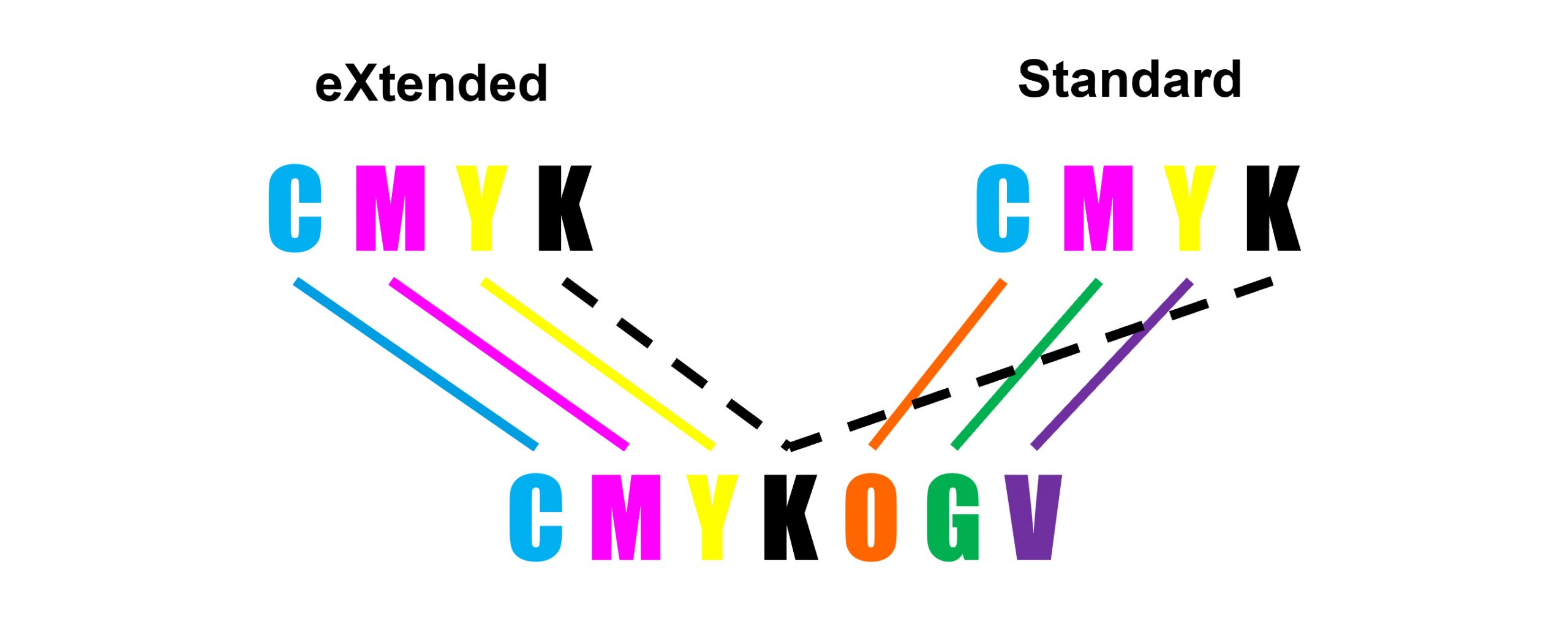

There are two primary DMS screens: a Standard screen with 300-400 lpi resolution, and an eXtended screen of 350-450 lpi resolution. The eXtended screen uses slightly smaller dots that are a little closer together, thereby enhancing fidelity, while the Standard screen has dots that are more robust.

Each screen uses a slightly different dot size, shape, and spacing in each color that ensures that they do not interfere with each other. The dot algorithm further interleaves the dots in one color with the dots in another producing what we call a ‘stochastic rosette’[1]. This eliminates screen angles and angle clashes, as well as moiré between the dots in the different colors.

Bellissima’s eXtended screen is helping flexo trade shops and converters win business from offset.

A label printer, based in Germany, was producing offset labels for a large European pharmacy brand. The printer was struggling to cope with increasing costs, in part due to 800 meters of offset make-ready waste each time he went on press with a particular job. The printer discussed his concerns with its trade shop, who suggested using flexo with Bellissima DMS screen plates instead.

The printer agreed, put the job on press, ran the job, and got to color much more quickly, reducing his make-ready waste down to 150 meters. The brand owner was more than happy and signed off on the labels. The label printer is now converting more of his offset work over to flexo with Bellissima, which is now his screening of choice.

Bellissima on wide web flexibles

The Bellissima Standard screen uses dots optimized for wide web printing and offers flexible packaging printers the ability to print at resolutions of 300-400 lpi.

Some printers may be concerned that the dots employed to produce such high fidelity may not be durable enough for use with long-run jobs.

The root cause of durability problems is unstable dots on a plate, and not small dots per se. Unstable dots can break off the plate, or they fatten up on press, causing dirty or muddy looking print. Bellissima DMS plates are capable of extremely long runs due to the underlying technology employed that created dots that are stable and durable.

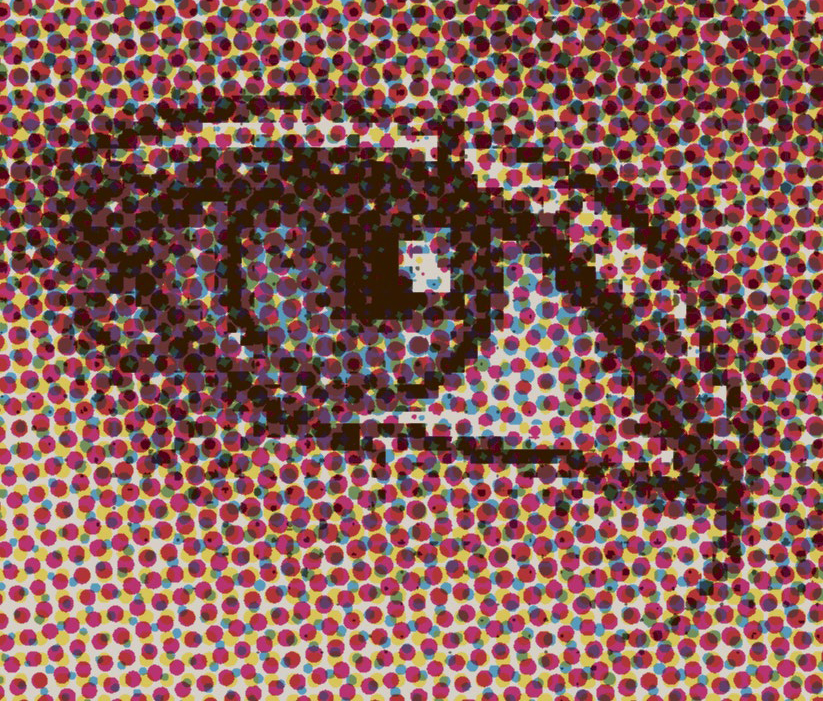

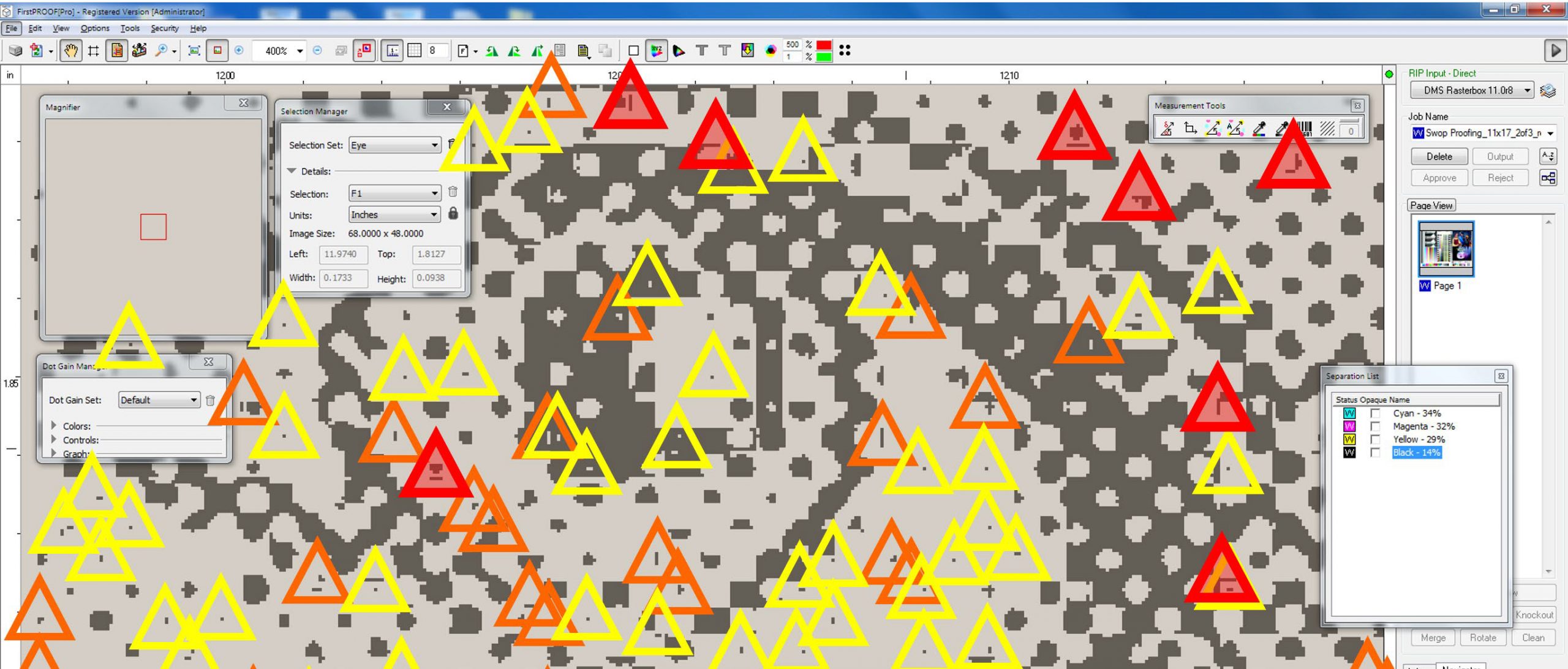

In the graphic shown below, many unstable (chopped) AM screened dots are visible, and during a print run, these can easily cause the problems already described.

Chopped dot removal tools can be used during repro in an attempt to reduce and remove some of these unwanted dots, but these tools only work partially, and the additional step in the overall process adds additional costs to the reprographics work.

The image above shows lots of chopped AM dots

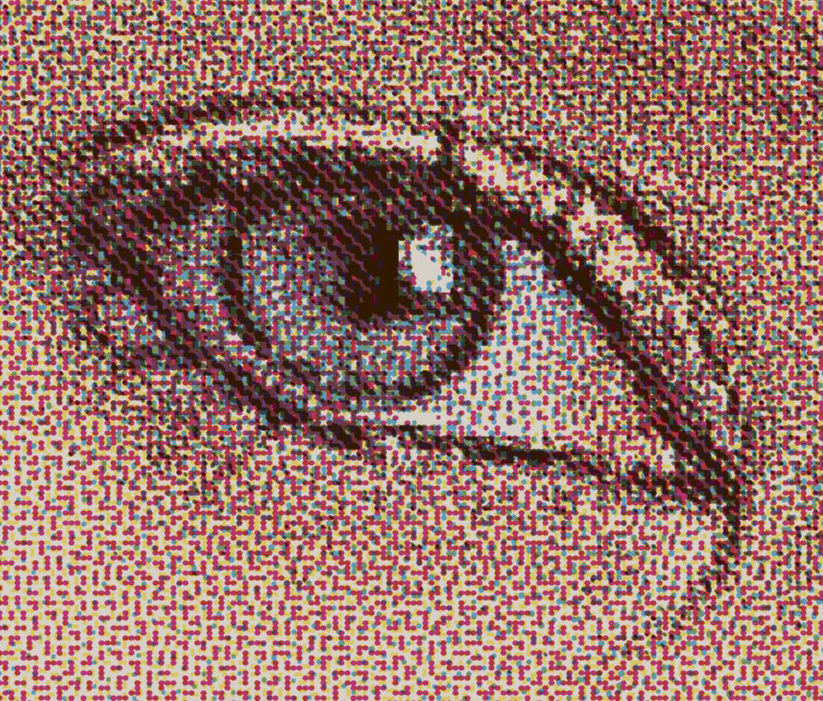

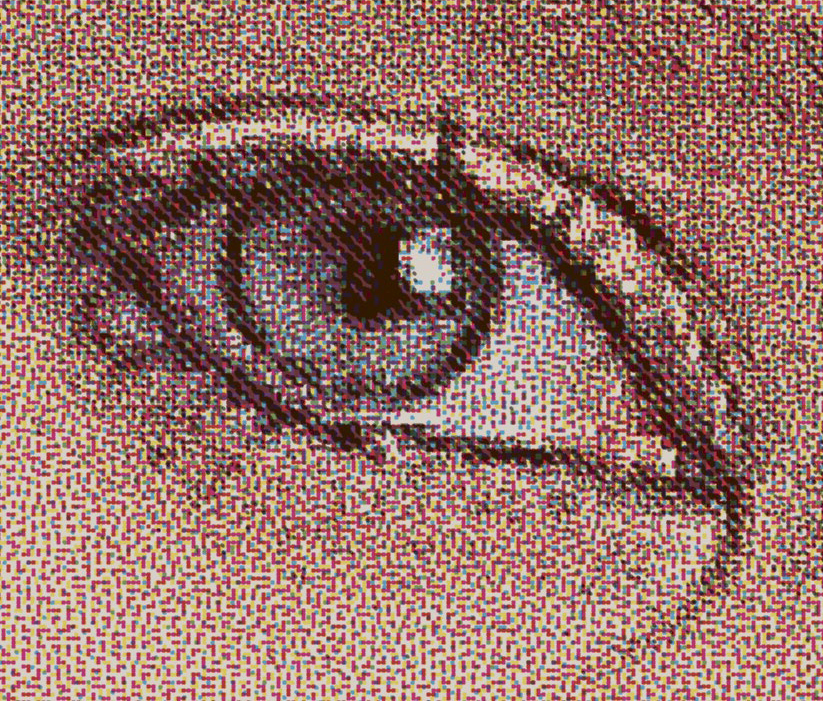

The Bellissima dot algorithm ensures that dots are more consistent in size and shape and are almost always supported by others to ensure that there are practically no lone, isolated dots or chopped dots to be imaged onto the plate. This provides stability on the press over long runs and reduces the work which the repro team needs to do, and this reduces costs.

Using Bellissima, we guarantee a minimum ‘base dot’ size (for example, a 3×3), which applies to almost all dots. The remaining ‘edge dots’ – these have a ‘white edge cutting through a ‘base dot’ – can be slightly smaller, but in this case, we have a second definition of a guaranteed minimum ‘edge dot’ (for example, a 2×2).

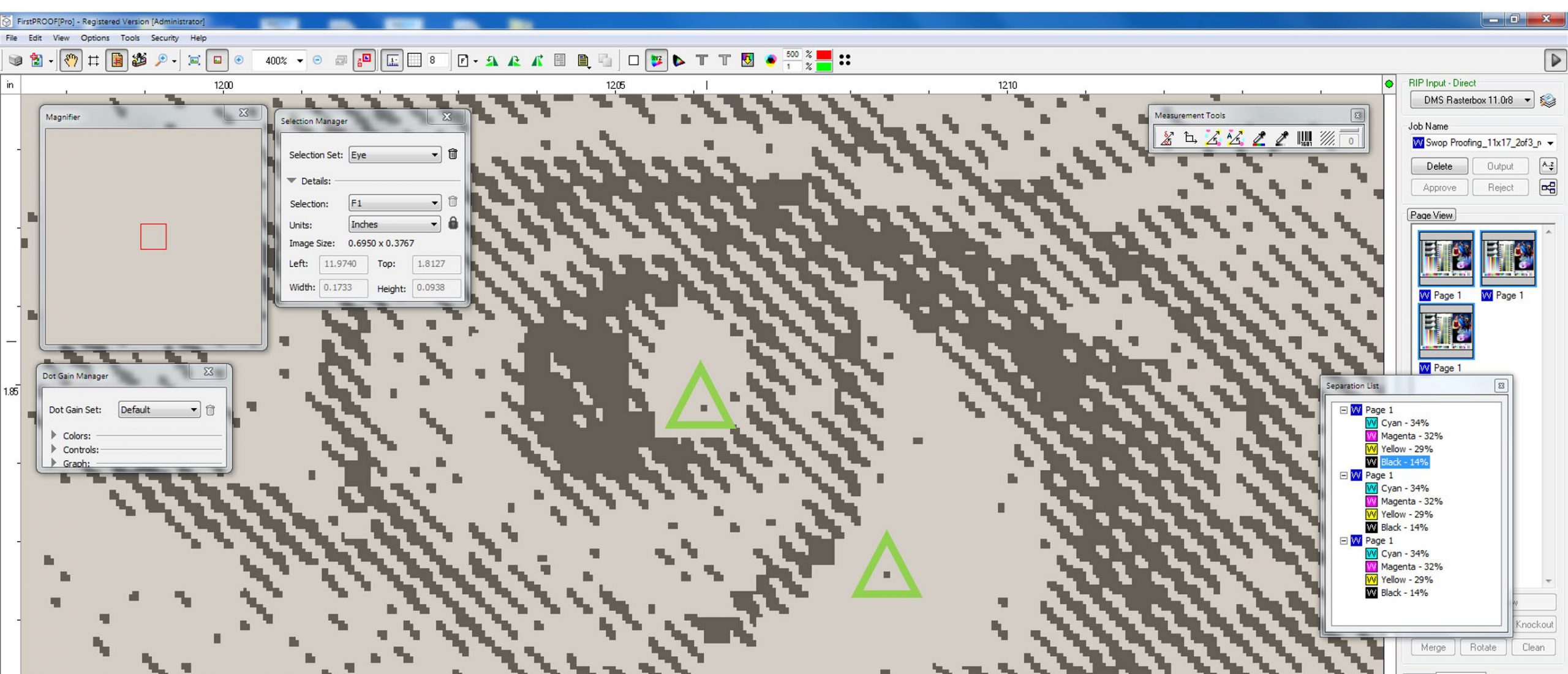

The next image shows precisely this. More than 95% of all dots shown in the image consist of guaranteed minimum ‘base dots’ (3×3), and a couple consist of guaranteed minimum ‘edge dots’ (2×2), the remainder being in-between (3×2 or 2×3).

These dots are known to image well and be stable on the plate; in turn, these factors ensure that printers using Bellissima plates can be successful over very long runs.

More than 95% of all dots shown in the image consist of guaranteed minimum ‘base dots’ (3×3), and a couple consist of guaranteed minimum ‘edge dots’ (2×2), the remainder being in-between (3×2 or 2×3).

One particular wide web flexibles printer has reported using a single set of Bellissima plates, imaged on MacDermid ITP60 material, for a job that ran at a full speed of 300 meters per minute for 1.6 million linear meters. The print results from the first pull to the last remained stable, consistent, and repeatable.

Extended Gamut / Fixed Palette

Utilizing a combination of the Standard and eXtended screens, Bellissima is a game-changer on the road to easy high-fidelity fixed palette/extended gamut printing.

Taking the CMY from the eXtended screen for CMY, and the CMY from the Standard screen for OGV and the K from either screen, printers can run seven-color prints on narrow and wide web very easily.

Bellissima’s patented stochastic rosette ensures that there is no interference between the dots in any of the colors and, therefore, no moiré. Bellissima delivers flat tints that are as smooth as spot colors and sharp tinted and reverse tinted text while exhibiting none of the limitations of conventional screens.

Bellissima has helped make one of FGS’s clients’ fixed palette vision a reality.

Flexographic Solutions S.L. (FGS) is a flexographic trade shop based in Barcelona, Spain. Specializing in the production and manufacture of photopolymers, ITR sleeves, and engraved elastomer plates, FGS has offered its pre-press services to printers of the flexible packaging market for more than 20 years.

Flexographic Solutions S.L. Spain

One specific customer of FGS, a wide web flexibles printer, was initially reluctant to print using more than four colors on its wide-web press and communicated its concerns to FGS regarding color stability when printing with fixed palette inks.

FGS discussed the benefits of Bellissima with the printer, who agreed to begin a test print.

Joan Rodriguez Cosano, Technical Director at FGS, comments: ‘The print test helped our customer to realize the results quickly, and after the test, he transitioned to running fixed palette jobs on the press full-time.’

‘Using Bellissima, the client has reduced the time on press by an hour per job due to the elimination of press wash-ups, shorter make-ready times, and reduced waste from misregistration issues. The printer has quantified this to be a 30% reduction in costs per job. This is excellent for the printer and FGS as it means that we can retain and grow the client.’

The printer is currently converting all its other printing presses to Bellissima DMS.

[1] Stochastic Rosette is protected by US Patents 9,508,031 and 9,787,872.

Click here to learn more about Bellissima DMS