AURAIA DMS CASE STUDY:

Silber Druck, Germany

Auraia DMS for Increased Productivity and Reduced Waste

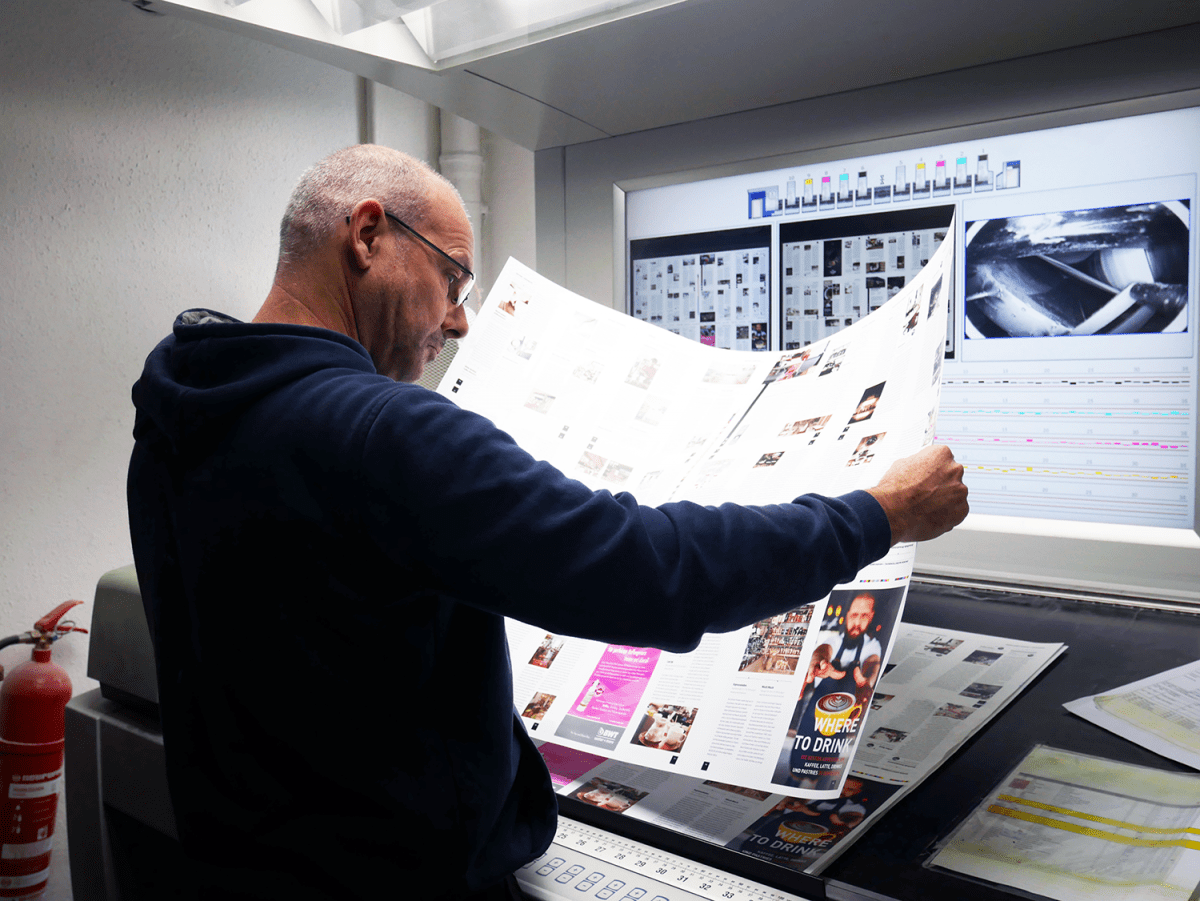

Located in Niestetal Germany, Silber Druck is a family owned offset printing business which has been in operation for over 50 years.

The business is now managed by the three Silber brothers: Wolfgang, Martin and Peter who took over operations from their father Heinrich Silber, who founded the business in 1965.

Silber Druck operates two KBA sheet-fed offset printing presses; one 8-color and one 10-color press and employs more than one hundred people including five in the prepress department and thirty in the press room.

The Problem

Silber Druck were producing printing plates using two Kodak Magnus 800 Platesetters, the plates were made using 200 lpi (80 lpcm) AM screening.

The press room team were experiencing difficulties with the on-press stability of the 200 lpi AM screen – colors were shifting, especially with the red tones, and they were having problems with grey balance.

Because of these problems, the make-ready waste was becoming a significant concern.

The Solution

In 2016 Silber Druck engaged in a project with their color consultant, Alfred Schmitz, of Schmitz At Work, to investigate how they could overcome the problems with the red tones and the grey balance. Schmitz At Work suggested they test Hamillroad Software’s Digitally Modulated Screening solution for offset – Auraia DMS.

The prepress and the press room team, worked closely with teams from Kodak and Hamillroad, to look at the overall process.

By including Auraia DMS as part of their prepress workflow, the team reported positive results: everything on press was stable, and the problems with the red tones and grey balance disappeared.

The Results

During the testing phase with Auraia DMS, they were quick to realise the benefits of the screening technology, the color problems had been resolved and they were able to achieve consistency and repeatability on press.

Impressed by the results demonstrated at Silber Druck, Kodak accredited Auraia DMS for use with the TH3 heads on the Magnus 800 Platesetter. In addition, Auraia DMS is now approved as part of the PSO, the Process Standard Offset, developed by Fogra in co-operation with the German Printing and Media Industries Federation.

The business benefits which Silber Druck reaped were significant: make-ready was reduced to 50 sheets, both KBA sheet-fed presses operate at full speed when Auraia DMS is used, and it is used on 98% of their printed jobs. For the past year, everything has been very stable, and the prepress and press room teams are very happy with the results.

Furthermore, Silber Druck have reduced waste during the post-print and binding stages; the ink drying time has been considerably shortened, and this has resulted in less paper curl and fewer jamming problems during the binding process. While Silber Druck don’t habitually measure their ink usage, they believe that, because the drying process has been reduced, they are using less ink than when they weren’t using Auraia DMS.

The prepress team are particularly happy with the smoothness of the flat tints they realise with Auraia - this wasn’t possible when using 200 lpi AM screening (80 lines per centimetre).

Having resolved their problems of instability and inconsistency, the company is now able to concentrate on growing its business. In 2019, Silber Druck will move into a new larger print facility and intend to add an additional press to their print operations, taking them from two to three KBA sheet-fed offset presses (2 x 8-color and 1 x 10-color). The managers are also planning to offer an e-commerce printing solution to customers.

Statement from customer:

Since we used GCR-backed data from Alwan ColorHub, our print production has stabilized tremendously. By combining Hamillroads Digitally Modulated Screening Auraia in conjunction with a sophisticated GCR, we are able to produce after about 20 startup sheets. We achieve a proof-faithful print quality over the entire run with a stable gray balance. Follow-up orders are easily reproducible. Production-related fluctuations, as e.g. caused by temperature fluctuations, different machine parameters, etc., are compensated by the use of Auraia DMS and GCR-computed data. Another significant advantage is the ink savings, the quick drying of the printed sheets and thus the possibility for immediate further processing of the respective printed product.Pressroom @ Silber Druck

Watch our Auraia DMS Heatset video:

The 5 Objections to Maximizing Heatset Profitability