BELLISSIMA DMS CASE STUDY:

Flexographic Solutions S.L. (FGS), Spain

Helping printers reduce costs and win new business

The Company

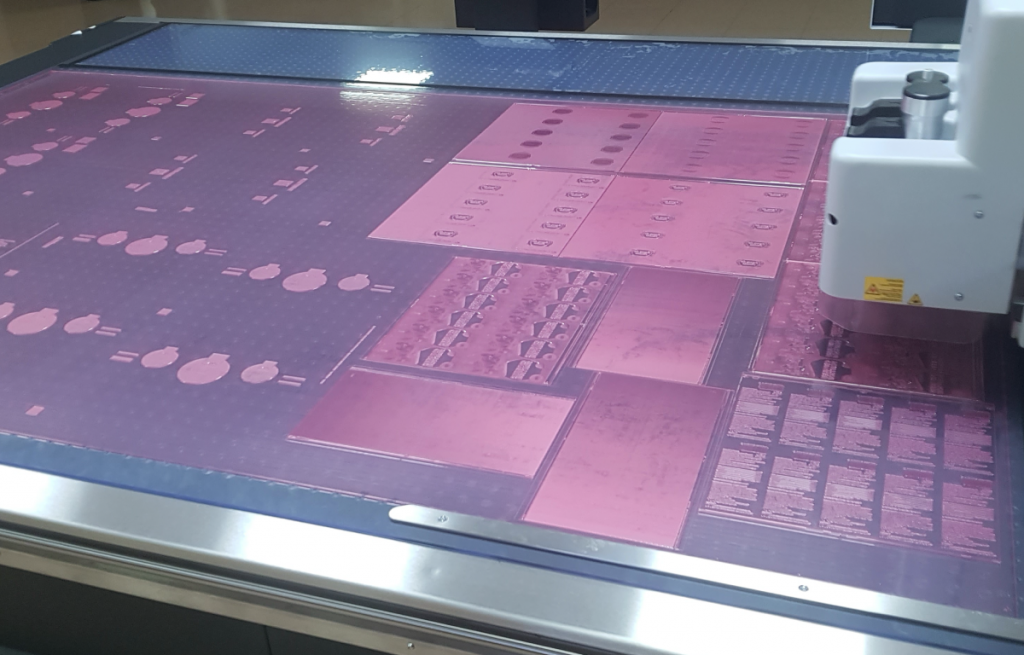

Flexographic Solutions S.L. (FGS) is a trade shop based in Barcelona, Spain, specializing in the production and manufacture of photopolymers, ITR sleeves, and engraved elastomer plates.

FGS has provided its prepress services to printers of the flexible packaging market for more than 20 years.

Joan Rodriguez Cosano is the Technical Director at FGS and a confessed image-quality enthusiast; ‘I am always looking for the best halftone screening. I believe that the screen is the secret to delivering the best images on press.’

‘Over the years, we have used different methods to enhance our customer’s print results, implementing various technology solutions, including MacDermid ITP 60 polymer plates, and investing in the latest CTP imaging solutions and CDIs.’ Rodriguez Cosano comments.

The Challenge

Rodriguez Cosano adds: ‘We’d been searching for the perfect screen to improve the high-lights, solids, and fades to zero; however, most of the screens that were available to us were developed around the existing AM screen.’

FGS was keen to differentiate its flexo plate making services in the Spanish and Portuguese markets. Joan and his team investigated many different options in the hunt for the right solution.

‘We knew that we needed to find a simple way of gaining an advantage over our competitors. The moment we identified Bellissima, and began tests, we were confident that we had found the key to successfully delivering the highest quality flexo print within the industry.’

We were confident that we had found the key to successfully delivering the highest quality flexo print

Making Expanded Gamut Printing a Reality

For one long-standing customer of FGS focussing on the flexible packaging market, their vision of moving to fixed palette printing has become a reality. They had been reluctant to use more than four colors on their wide-web presses because of concerns about color stability. Still, after discussing their concerns with FGS, they agreed to a print test using Bellissima DMS plates.

Joan comments: ‘The print test helped our customer to realize the results quickly, and, after the test, they transitioned to running fixed palette jobs on the press full-time.’

‘Using Bellissima, the client has reduced the time on press by one hour per job due to faster make-ready times and removed the waste caused by misregistration. The printer has quantified this to be a 30% reduction in costs per job. This is excellent for the printer and FGS as it means that we can retain and grow them as customers.’

That same flexible packaging printer is currently converting all other printing presses to Bellissima DMS.

When asked about the feedback from other people within FGS and customers, Joan states: ‘The team at FGS is incredibly positive about Bellissima; they see the difference it makes to our customers and is happy to see it helping us to attract new business.’

‘The feedback from our customers is varied – they are not always initially happy about any increment on the price. Many printers don’t consider that they had print quality problems in the first place; however, it’s when you can get on press with them and demonstrate the real tangible cost and time savings they become interested in Bellissima. The marginal cost increase concern rapidly evaporates once they realize the ROI benefits of Bellissima.’

No other screen ruling or technology available can compete with what we can deliver using Bellissima

The Business Benefits

Bellissima has started many new conversations and business opportunities for FGS.

‘Having a robust offering that delivers the highest flexo print quality while also helping printers reduce costs makes for a very compelling sales story,’ boasts Joan.

‘It offers a new print standard for the flexographic industry - it is now quicker and easier to achieve high-definition print reproduction with less effort in prepress. No other screen ruling or technology available can compete with what we can deliver using Bellissima,’

On the working relationship with Hamillroad as a supplier to FGS, Joan says: ‘Our relationship with Hamillroad has been excellent since the beginning. The support has been swift to help and answer our questions on the rare occasions we have had to ask. In my opinion, there is no supplier in the market like Hamillroad – their team works closely with us to achieve the excellent results for the client projects we fulfill.’

‘Hamillroad and Bellissima DMS are matched to FGS’ needs - as we continue to work together, we will further improve the technology. Hamillroad has demonstrated a willingness to receive feedback from the press room floor and take that information to develop new software features – this, in return, gives us more capabilities and benefits that we can pass onto our customers.’

‘I look forward to continued collaboration and support from Hamillroad as FGS is the exclusive partner for Bellissima DMS for the wide-web flexibles market in Spain and Portugal,’ concludes Joan.