Auraia DMS – Reduce costs

Auraia DMS is proven to reduce costs compared to AM and FM screening, delivering real-world ink savings as well as a reduction in waste, water, and energy. Crucially, there is no compromise on quality. Auraia DMS is held in high regard by Publications for its ability to produce photo-real image fidelity in stunning magazines, catalogs and books, which results in a reduction in customer charge backs.

Attract new clients and compete on price...

12-18% Reduction in ink

Using Auraia DMS, your heatset printing business can expect to achieve ink savings in the region of 12-18% (up to 35% measured). These savings are in addition to any already achieved using GCR software.8-10% Reduction in water

Auraia DMS can lead to an 8-10% reduction in water usage by requiring a decrease in press water levels due to reduced ink placement on each dot.Reduction in energy costs

With less ink and water being used, the drying process is reduced meaning that less heat (gas) is required to dry the substrate.Reduction in waste

With Auraia DMS you will achieve reduced waste and a reported 50% faster make-ready times due to ease of registration.Testimonials

How is this possible?

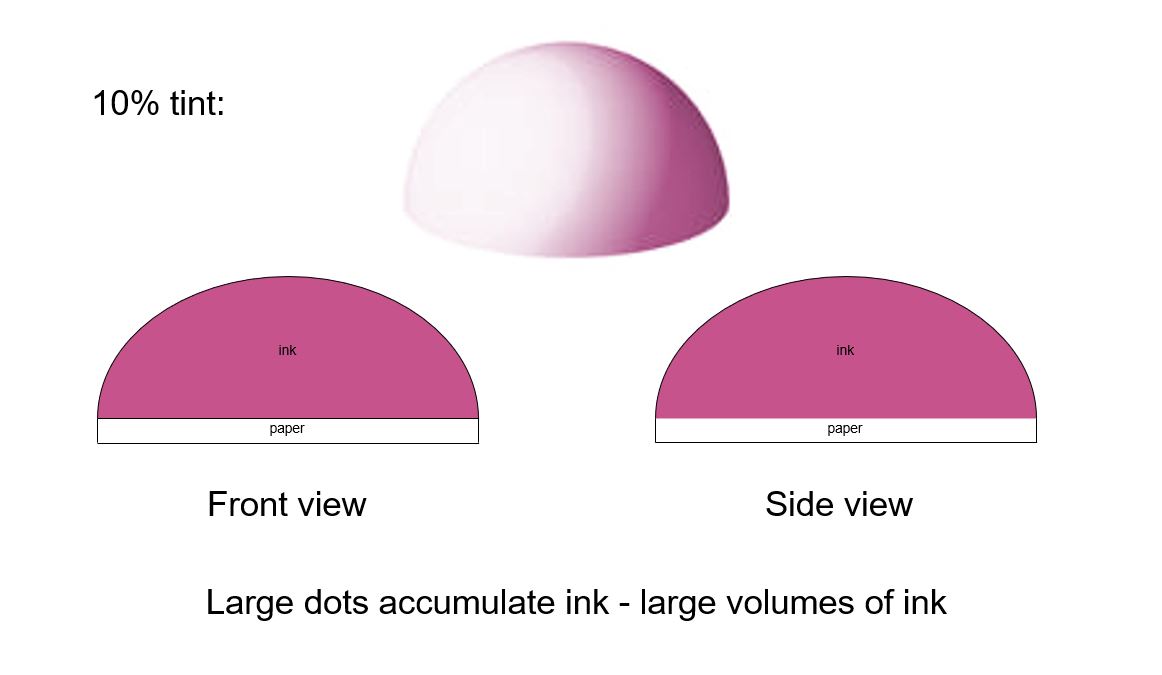

Our patented 'stochastic rosette' maximises the amount of ink-on-paper and minimises the amount of ink-on-ink.

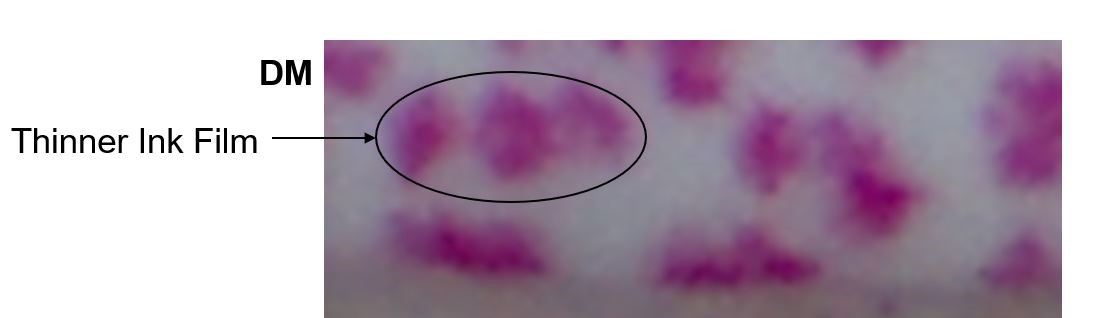

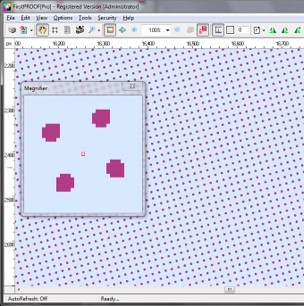

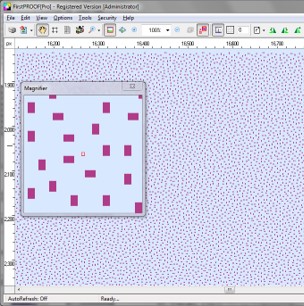

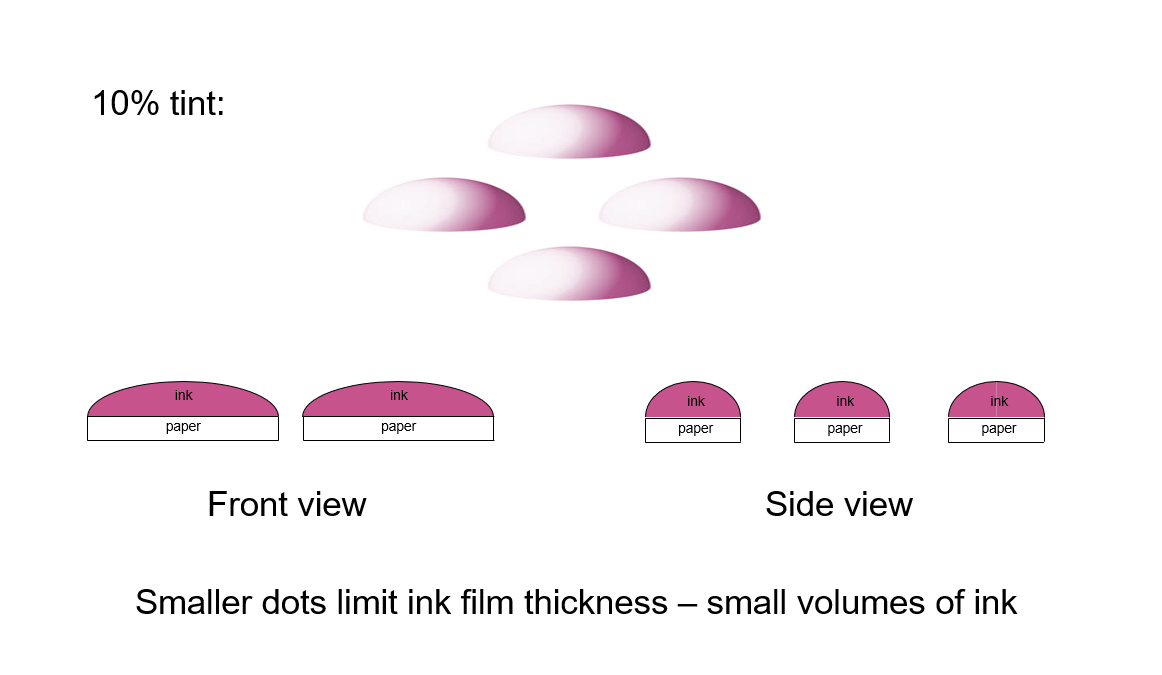

DM dot structure uses smaller dots than AM dot structure

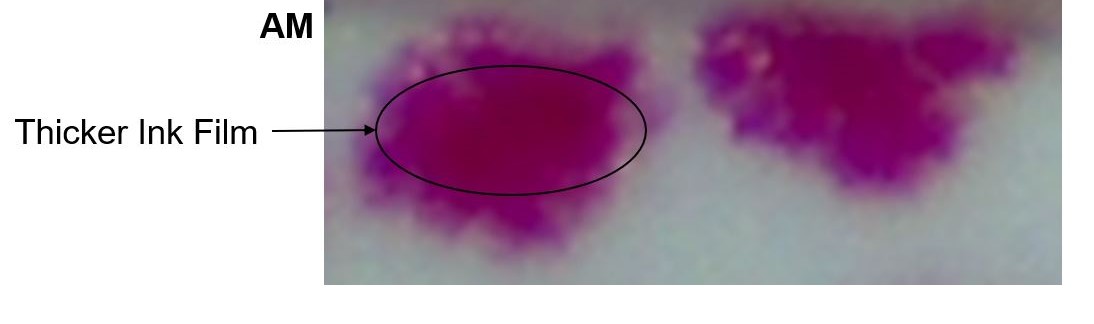

AM (Amplitude Modulated) dot structure

DM (Digitally Modulated) dot structure

AM ( Amplitude Modulated) Ink volume

DM (Digitally Modulated) Ink volume

Theoretical illustration of what ink volume look like on paper

AM (Amplitude Modulated) dot

DM (Digitally Modulated) dot