Bellissima EVO

Evolved DMS Screening technology for beautiful,

greener packaging that saves printers time and money.

ULTRA HIGH-DEFINITION FLEXO

REDUCE TIME

& COSTS

“ The goal was to convert 32 brand spot colors to 4-color process to reduce printing costs. The result: the spot colors now converted to process appeared smooth and uniform. ”

Ken Pavett, CEO,

Flexografix

INCREASE PRINT

CAPACITY

“ The client has reduced the time on press by one hour per job due to faster make-ready times and removed the waste caused by misregistration. The printer has quantified this to be a 30% reduction in costs per job. ”

Joan Rodriguez Cosano,Technical Director, FGS

REDUCE INK

& WASTE

“ When using ECG alongside Bellissima, we can achieve constant print speeds and superior HD quality. We also see the benefit of keeping make-ready time and waste to a minimum. ”

Gustavo Rebaque, Production Manager, Petropack

STUNNING

SHELF APPEAL

“ Bellissima’s advanced screening ensures flawless ink laydown while maintaining exceptional detail and sharpness. The result is vibrant, high-impact packaging that brands have never seen before. ”

Steve Cooney, Graphics Manager, StarPak

BRANDS LOVE BELLISSIMA!

UNBELIEVABLE IMAGE FIDELITY - GIVE YOUR BUSINESS A COMPETITIVE EDGE

Achieve exceptional print quality that sets you apart. Bellissima achieves ultra-high-definition results with smooth vignettes, sharp detail, and unrivalled consistency, giving brands the confidence to choose flexo over other print processes. Request a sample and discover how Bellissima can help you win more business.

Significantly Increase Your Print Capacity

Bellissima enables fixed palette printing (CMYK + ECG), eliminating the need for spot colors and reducing press wash-ups. With faster job changeovers and improved press utliziation, you can significantly increase your press output and chargeable jobs.

Reduce costs by switching to Bellissima DMS

Give brand owners a point of difference, print more sustainablY

STUNNING SHELF APPEAL

Brands are no longer restricted with design options for labels and packaging. We’ve helped achieve what was previously impossible with conventional flexo screening, and we’ve won multiple production awards to prove it!

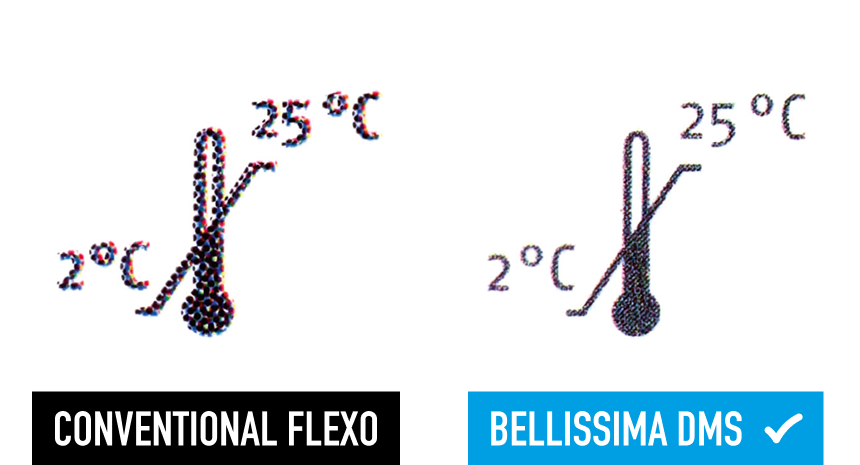

Smooth fades to zero

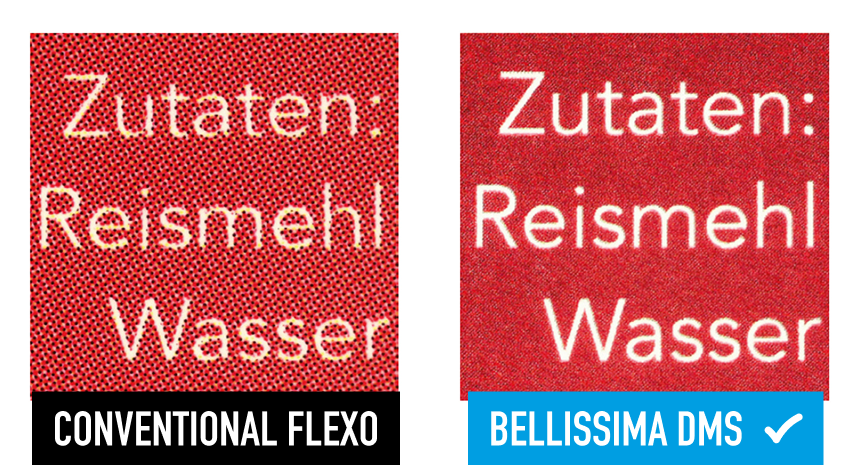

Sharper reverse/tinted text

Produce fine text and details without degradation

Reduced repro (time & cost)

Less work is required in reprographics to touch-up files

No screen moiré

No angles = no clashes = no moiré

Exceptional shadow depth & details

Printed shadow dots up to 99.5%

Ultra HD flexo – small elements

are clearly defined

Recreate flat tints moiré-free

Sharp, legible small text & clean fine

details with processed colors

Smooth multi-color blends

Fine elements and gradients

Smooth 7 Color ECG printing

with no degradation of fine details

PRESSROOM OPTIMIZATION

Our global network of Bellissima suppliers and reprographics experts are helping printers and converters to reduce costs and maximize efficiency in the pressroom.

We’re converting more jobs to expanded gamut; this is helping our converter customers reduce job setup times and waste – a typical example of this is from 2 hours, down to 20 minutes

Diego Zarlenga, General Manager,

Fotograbados Lynch

Faster

Make-Ready

Customers are impressed by the reduction in process costs – shorter setup times, coupled with increased productivity.

no color

shift

The dots in one color interleave with the dots in another color, which eliminates color shifts caused by misregistration.

use less

ink

Approximately 10% of ink can be expected for typical production jobs compared to printing with a traditional AM screen.

Longer

Runs

2.5 million linear meters reported on one set of plates - Wide Web flexibles using solvent ink.

FIXED PALETTE ECG PRINTING

Printed packaging often introduces a particular sustainability message to consumers by communicating how environmentally friendly the brand and product are; to be genuinely beneficial, the packaging must deliver more than a positive planet-friendly face and an eco badge of approval.

Looking closely at a product's packaging you will often see that a combination of process colors and spot colors are used.

The more spot colors used to print a job equates to more ink going into landfills, which means more processes and chemicals are required to recycle the packaging. In addition, the reality of print production is that more chemicals and solvents are required to wash up the press between production jobs where spot colors are used.

By switching to fixed palette printing and adopting a CMYK + OGV (Expanded Color Gamut ECG) environment, you can run job after job, covering an expanded gamut, reducing the number and frequency of ink station wash-ups, thereby reducing the amount of chemicals used in the process.

Land Juweel see this as a fantastic result as our production has reduced the use of inks and solvents to produce more environmentally friendly labels for the brand