BELLISSIMA DMS CASE STUDY:

Petropack, Argentina

An Exciting Future with Bellissima

The Company

With more than 30 years of experience producing flexible packaging, Petropack is a family-run printing business based in Paraná, Argentina.

A key industry leader in packaging technology, Petropack prides itself on meeting high-capacity customer demands without compromising results. Petropack ensures that customers receive the best quality standards from initial engagement through to product output.

"We want to be the best at what we do, "says Gustavo Rebaque, Production Manager, Petropack. "One of our key philosophies is continuous investment in cutting-edge technology which guarantees our products meet customer needs."

"We recognize the importance of being a mission-critical business in the supply chain, responding to the ever-increasing and changing demands of the FMCG market, ultimately making us the number one choice for flexible packaging print in Argentina."

"We want to be the best at what we do"

The Challenge

Petropack sought a solution to complement its existing print production without needing to make a large capital investment. "Our main challenge was to match the quality produced by rotogravure, but at a lower price point and with shorter lead times by using flexo."

"We identified the need to be agile and remain competitive in our market to retain and win business; we had to improve productivity and process stability while not increasing costs - this always seemed unattainable to us." Comments Gustavo.

The Solution

"Working closely with our trusted suppliers, Fotograbados Lynch and MacDermid Graphics Solutions, we found the solution to our problem!" states Ariel Botti, Inks, Mounting and Planning manager, Petropack.

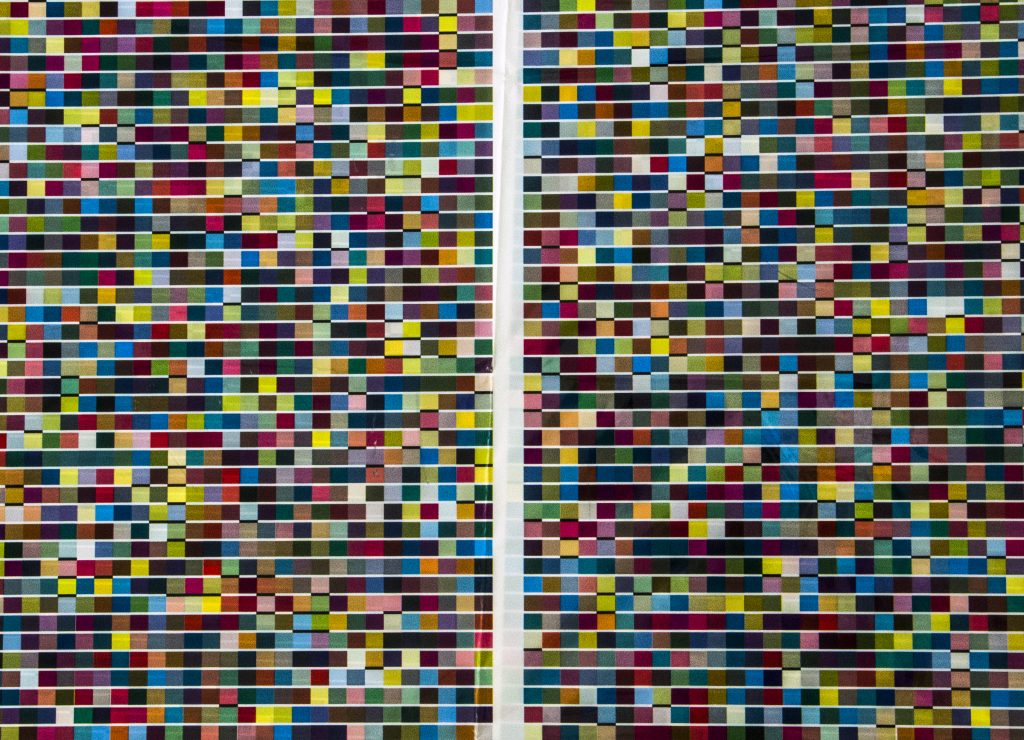

"In the past, we had experienced problems with high lpi screens; however, when Lynch and MacDermid presented us with an innovative solution in Bellissima (300-400lpi equivalent) on MacDermid Graphics Solution LUX ITP 60 plates, we immediately saw the potential to address the market demands of shorter runs while also reducing our costs."

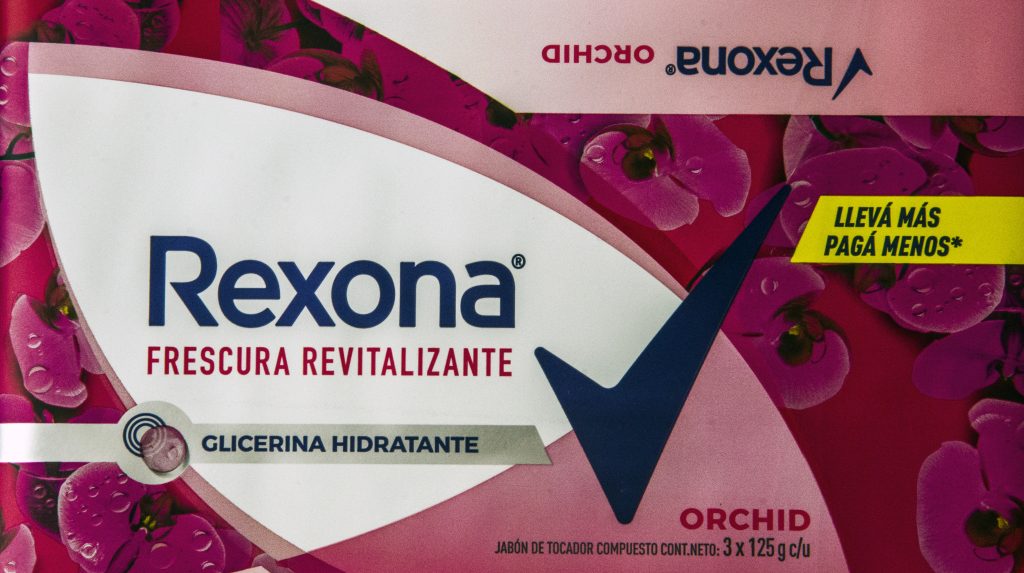

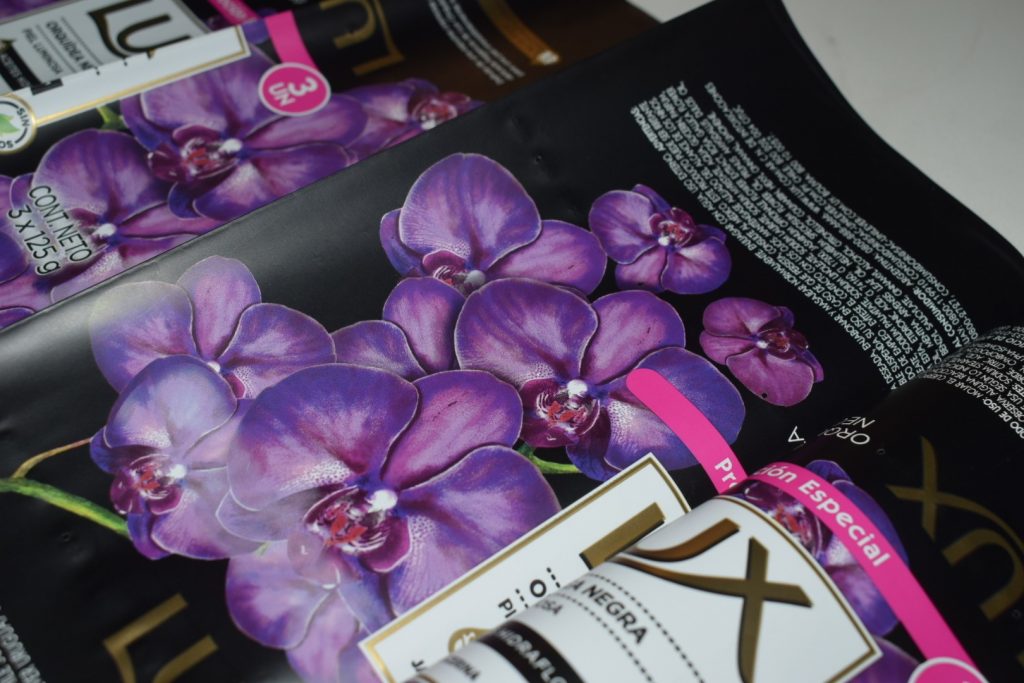

The discovery of Bellissima was a breakthrough for the business. "We received print samples of Bellissima on wide web flexibles and recognized that we had found a technology in flexo that would allow us to rival that of gravure production. It would also allow us to utilize our existing fleet of flexo printing presses, making the adoption process easier and cheaper to implement without the need to invest in any additional or specialized equipment. It was very simple!” Concludes Ariel.

Brand Owner Acceptance

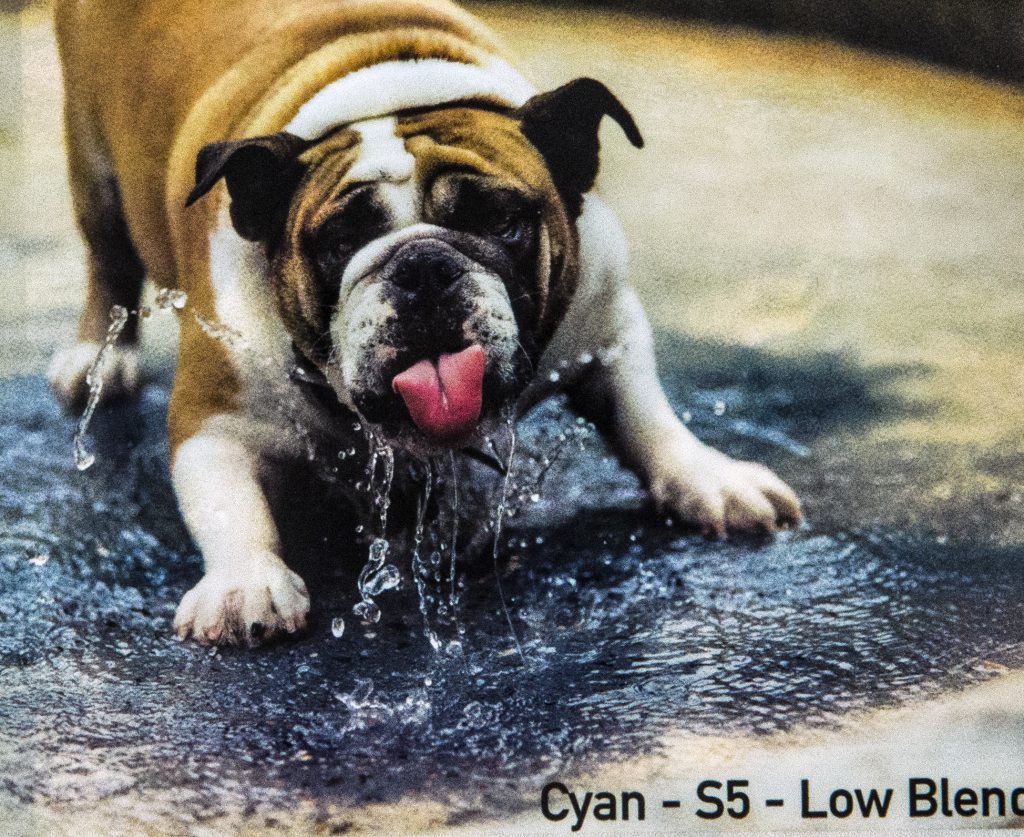

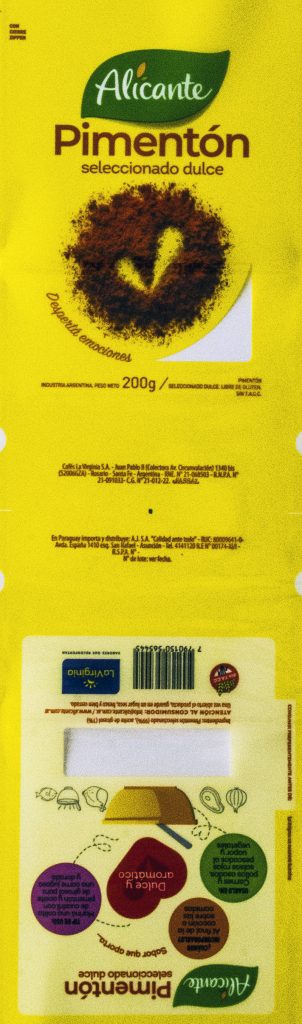

The outstanding result for Petropack was the positive feedback from their customers, both existing and new. Gustavo explains, "Once we started to show the brand owners the results, they were impressed. One particular brand owner had clear success criteria of objectives that had to be met – excellent fades to zero and the ability to hold fine details."

The brand owner and Petropack began a project to move a specific product line across from gravure to flexo. The project was a success and resulted in the brand owner agreeing to move additional SKUs across to flexo. "The customer was amazed at the results and happy that we could deliver the print faster than it would've been using gravure."

"The discovery of Bellissima was a breakthrough for the business."

Business Benefits

"As a business, we focus on keeping customers satisfied while also managing costs and expectations. One of Bellissima's benefits has been that the plates are very stable and last for long-runs; this has had a noticeable impact on reducing our production waste and keeping costs to a minimum."

Additional benefits of switching jobs from gravure include reducing its chemical use, which helped Petropack further enhance its company values of respecting the community and the environment and improving its service offerings.

Petropack also discovered they could make use of Extended Colour Gamut (ECG). "Using ECG helps us to reduce job set-up times, and the number of plate changes significantly. Using ECG alongside Bellissima, we can achieve constant print speeds and superior HD quality throughout the entire print run while also keeping make-ready time and waste to a minimum," concludes Gustavo.

"Undoubtedly, the most outstanding benefit has been the growth we achieved since adopting Bellissima. The flexo quality we now produce for some of our longest-standing customers is unrivaled, and as a result, they have been more than happy to assign more projects to us."

The happy customers, coupled with the overall reductions in costs and the environmental benefits, have created a successful flexo offering for Petropack.

"We've not looked back. We have staked a part in the future of flexible packaging and lead the way in Argentina – it's an amazing position to be in; we are excited for the future opportunities working with Bellissima."